Preparation method for detecting explosive sensitive thin-film

A technology for sensitive thin films and explosives, applied in material excitation analysis, fluorescence/phosphorescence, etc., can solve the problems of time-consuming, cumbersome process, and high raw material cost, and achieve the effects of improving preparation efficiency, good repeatability, and fast stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] a. Prepare polymer solution: Dissolve fluorescent polymer (such as MEH-PPV, coumarin, PPV derivatives, etc.) in chloroform or toluene at a concentration of 1-1.5mg / ml; b. Pretreatment: silicon wafers are cut into approximately 1 × 1cm-sized silicon wafers; silicon wafers and glass wafers are treated with hydrogen peroxide (H 2 o 2 ) Ultrasonic cleaning for 5 minutes, then ultrasonic cleaning with deionized water for 5 minutes, ultrasonic cleaning with ethanol for 5 minutes, and finally immersing it in ethanol for use; The spray gun blows off the dust and liquid droplets on the surface; the speed of the homogenizer is 400--700r / min, and the speed is kept for 6s; —80um fluorescent film material. d. Apply the obtained film to a small explosive detector (patent number: 20122066387.4), and detect explosives according to the phenomenon of fluorescence quenching.

Embodiment 2

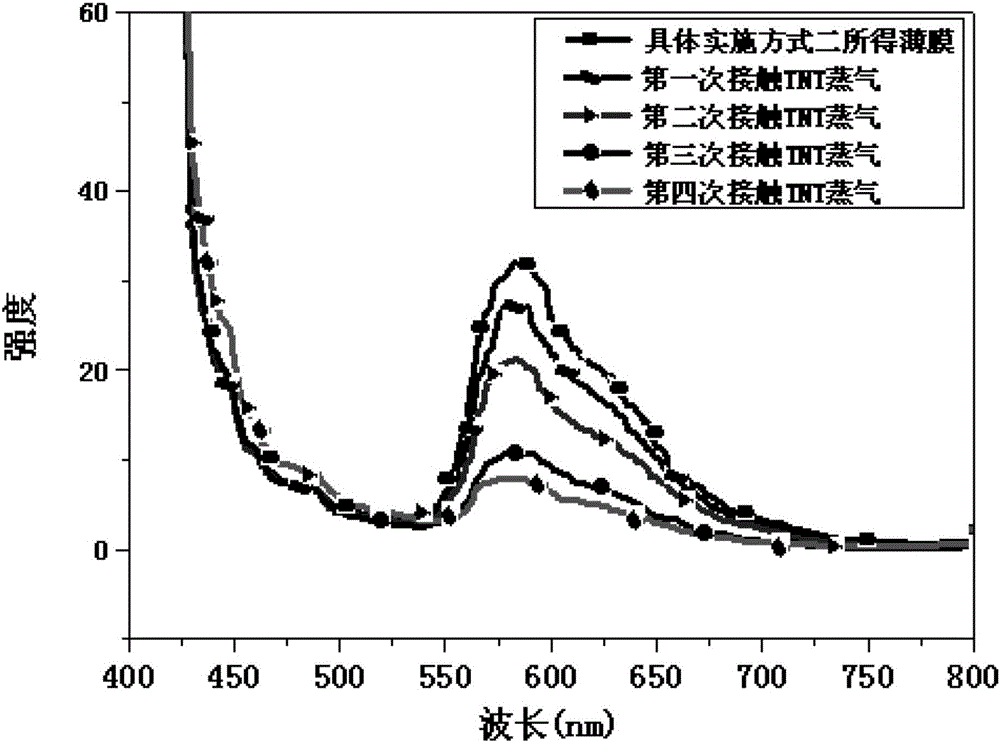

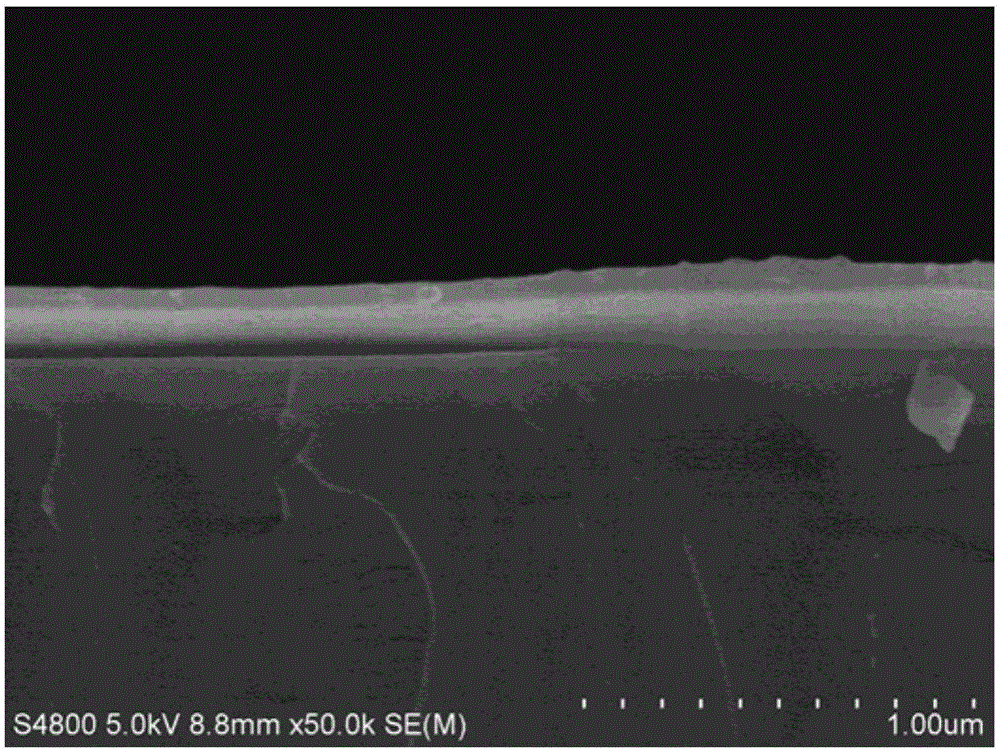

[0018] a. prepare polymer solution: dissolve fluorescent polymer (such as MEH-PPV) in chloroform or toluene, concentration is 1.2mg / ml; b. pretreatment of silicon wafer and glass wafer: silicon wafer is cut into about 1 ×1cm silicon wafer; silicon wafer and glass wafer with hydrogen peroxide (H 2 o 2 ) Ultrasonic cleaning for 5 minutes, then ultrasonic cleaning with deionized water for 5 minutes, ultrasonic cleaning with ethanol for 5 minutes, and finally immersing it in ethanol for use; The spray gun blows off the dust and liquid droplets on the surface; set the glue leveling machine speed 1 to 0r / min and the glue leveling speed 2 to 1000r / min to keep the parameters for 40s. During the glue leveling speed 2, drop 2 The polymer fluorescent material is dropped to obtain a fluorescent thin film material with uniform thickness.

Embodiment 3

[0020] a. prepare polymer solution: dissolve fluorescent polymer (such as MEH-PPV) in chloroform or toluene, concentration is 1.2mg / ml; b. pretreatment of silicon wafer and glass wafer: silicon wafer is cut into about 1 ×1cm silicon wafer; silicon wafer and glass wafer with hydrogen peroxide (H 2 o 2 ) Ultrasonic cleaning for 5 minutes, then ultrasonic cleaning with deionized water for 5 minutes, ultrasonic cleaning with ethanol for 5 minutes, and finally immersing it in ethanol for use; The spray gun blows off the dust and liquid droplets on the surface; set the glue leveling machine speed 1 to 0r / min and the glue leveling speed 2 to 2000r / min to keep the parameters for 40s. During the glue leveling speed 2, drop 2 The polymer fluorescent material is dropped to obtain a fluorescent thin film material with uniform thickness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com