Glass furnace air-fuel ratio adjustment method based on variable universe fuzzy rule iterative learning

A glass kiln, theoretical air-fuel ratio technology, applied in control/regulation systems, instruments, adaptive control, etc., can solve problems such as combustion efficiency, energy consumption, exhaust gas emissions, and adverse effects on glass product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

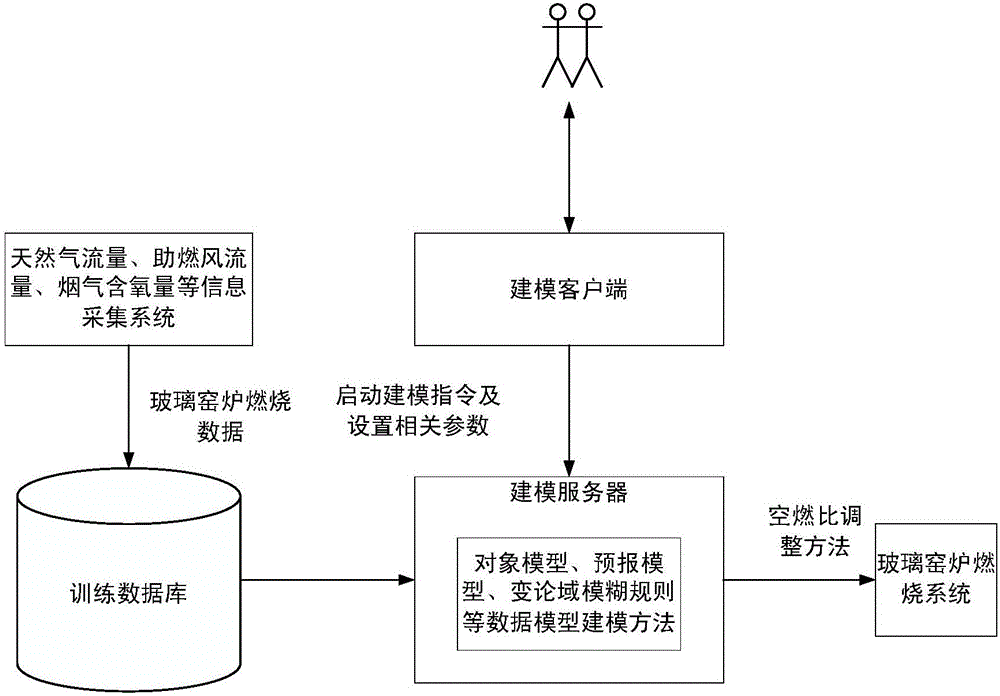

[0073] The dispatching method of the present invention relies on the relevant data acquisition system, and is realized by a modeling client and a modeling server. The schematic diagram of the hardware and software architecture of the present invention applied in the actual glass furnace is as follows: figure 1 As shown, the embodiments of the present invention are as follows.

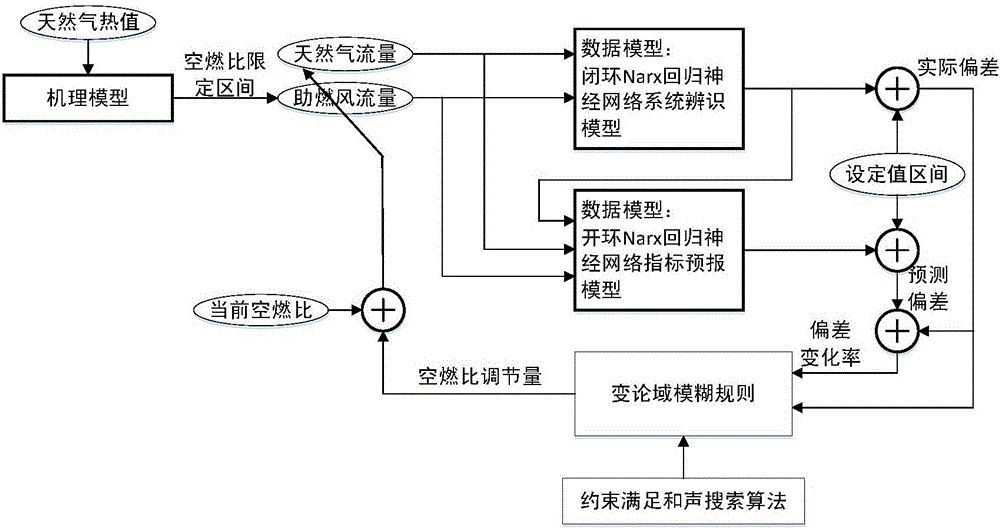

[0074] Step (1): Initialize, set the following basic variables

[0075] Set the problem variables:

[0076] x 1 (t): natural gas flow rate at time t

[0077] x 2 (t): Combustion air flow at time t

[0078] y(t): Oxygen content of flue gas at time t

[0079] [y min ,y max ]: Range of flue gas oxygen content setting value

[0080] △C: Air-fuel ratio adjustment amount

[0081] C: actual air-fuel ratio

[0082] CT: theoretical air-fuel ratio

[0083] CGas: Calorific value of natural gas

[0084] Step (2): Data Acquisition

[0085] Collect one or more production shifts including the above natur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap