Quantum dot light-emitting layer and device and preparation method, light-emitting module and display device

A quantum dot luminescence and quantum dot technology, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of uneven luminescence, low performance, and uneven thickness of the device, so as to improve the uniformity and stability of luminescence and improve the luminescence Efficiency and luminous life, the effect of film stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

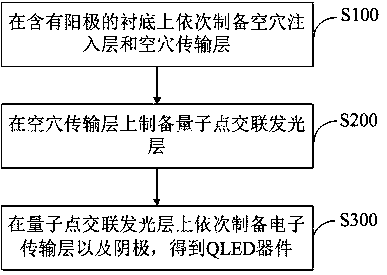

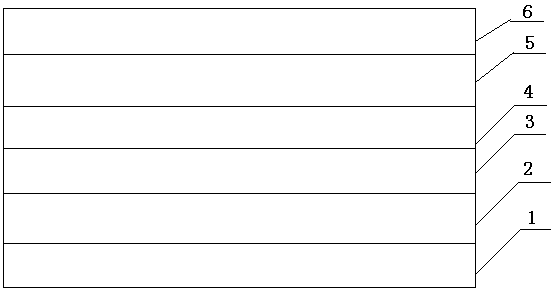

[0066] The preparation steps of the QLED device are as follows:

[0067] Spin-coat a layer of PEDOT:PSS thin film on the ITO substrate as the hole injection layer;

[0068] Spin-coat a layer of PVK on the PEDOT:PSS layer as a hole transport layer;

[0069] Spin-coat a layer of CdSe@ZnS coated with mercaptopropionic acid (MPA) ligands on the PVK layer as the quantum dot light-emitting layer;

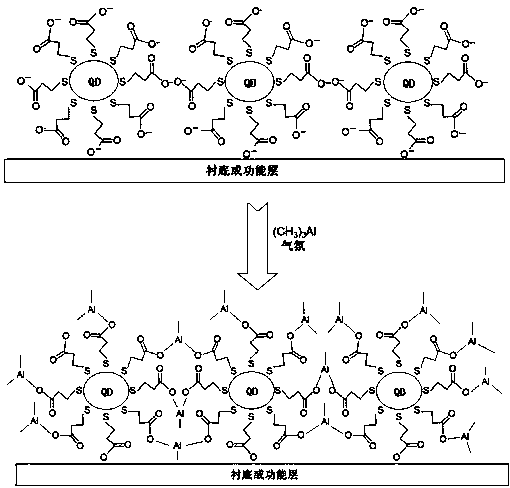

[0070] Next, the above-prepared CdSe@ZnS layer coated with mercaptopropionic acid (MPA) ligands was placed in a vacuum cavity, and trimethylaluminum ((CH 3 ) 3 Al) gas, where the internal pressure of the cavity is 0.05 mbar, the partial pressure of trimethylaluminum gas is 0.01 mbar, the internal temperature of the cavity is 16 °C, and the processing time is 5 min. Take it out after the processing to obtain the cross-linked quantum dots luminous layer;

[0071] Then, spin-coat one layer of ZnO on the quantum dot cross-linked luminescent layer prepared above as an electron transport la...

Embodiment 2

[0074] The preparation steps of the QLED device are as follows:

[0075] Spin-coat a layer of PEDOT:PSS thin film on the ITO substrate as the hole injection layer;

[0076] Spin-coat a TFB layer on the PEDOT:PSS layer as a hole transport layer;

[0077] Spin-coat a layer of CdSe@ZnS coated with mercaptopropionic acid (MPA) ligands on the TFB layer as the quantum dot light-emitting layer;

[0078] Next, the above-prepared CdSe@ZnS layer coated with mercaptopropionic acid (MPA) ligands was placed in a vacuum cavity, and trimethylaluminum ((CH 3 ) 3 Al) gas, where the internal pressure of the cavity is 0.05 mbar, the partial pressure of trimethylaluminum gas is 0.02 mbar, the internal temperature of the cavity is 18 °C, and the processing time is 10 min. Take it out after processing to obtain quantum dot crosslinking luminous layer;

[0079] Then, spin-coat one layer of ZnO on the quantum dot cross-linked luminescent layer prepared above as an electron transport layer;

[00...

Embodiment 3

[0082] The preparation steps of the QLED device are as follows:

[0083] Spin-coat a layer of PEDOT:PSS thin film on the ITO substrate as the hole injection layer;

[0084] A layer of TFB was spin-coated on the PEDOT:PSS layer as a hole transport layer;

[0085] Spin-coat a layer of CdSe@ZnS coated with oleic acid (OA) ligand on the TFB layer as the quantum dot light-emitting layer;

[0086] Next, the above-prepared CdSe@ZnS layer coated with oleic acid (OA) ligands was placed in a vacuum chamber, and triethylaluminum ((CH 3 CH 2 ) 3 Al) gas, where the internal pressure of the cavity is 0.05 mbar, the partial pressure of triethylaluminum gas is 0.01 mbar, the internal temperature of the cavity is 18 °C, and the processing time is 20 min. Take it out after processing to obtain quantum dot crosslinking luminous layer;

[0087] Then, spin-coat one layer of ZnO on the quantum dot cross-linked luminescent layer prepared above as an electron transport layer;

[0088] Finally, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com