Ti4O7-coated modified lithium titanate composite material and preparation method thereof

A titanium oxide and composite material technology, applied in the field of lithium ion batteries, can solve the problems of poor cycle performance of lithium ion batteries, poor corrosion resistance of carbon materials, easy structural changes, etc., to improve rate performance and cycle stability. The effect of passivation and corrosion resistance passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

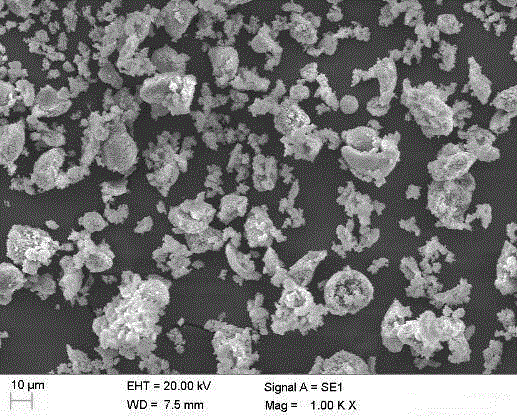

[0015] (1) Dry nanoscale lithium titanate powder at 200°C for 2 hours; (2) Mix butyl titanate and absolute ethanol at a volume ratio of 1:4 with a stirrer, and gradually add acetic acid and Deionized water, the volume ratio of acetic acid and butyl titanate is 1:5.5, the volume ratio of deionized water and butyl titanate is 1:10, stir for 3 hours to obtain a uniform sol solution; (3) according to the lithium titanate and titanium The molar ratio of butyl ester is 4.5:1. Add lithium titanate powder into titanium oxide sol solution, stir for 6 hours, vacuum filter, and vacuum dry at 30°C for 10 hours to obtain precursor powder; (4) The precursor powder was reduced in a hydrogen atmosphere furnace at 830°C for 6 hours, cooled to 100°C and released from the furnace to obtain titanium oxide-coated modified lithium titanate composite material.

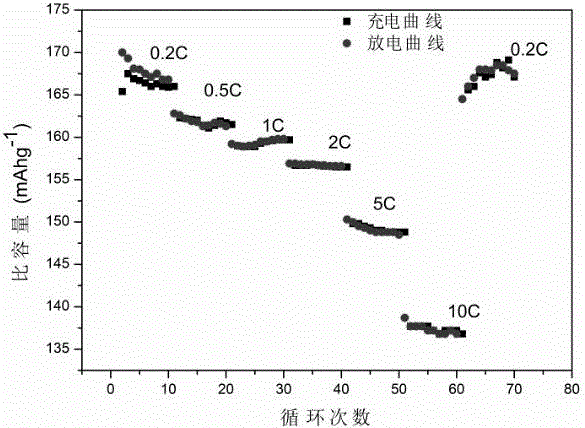

[0016] Using a lithium sheet as the negative electrode, make a button battery in a glove box filled with argon, and do a constant current c...

Embodiment 2

[0018] (1) Dry micron-sized lithium titanate powder at 30°C for 10 hours; (2) Mix butyl titanate and absolute ethanol at a volume ratio of 1:2 using magnetic stirring, and gradually add acetic acid and remove Ionized water, the volume ratio of acetic acid and butyl titanate is 1:2, the volume ratio of deionized water and butyl titanate is 1:10, stir for 24 hours to obtain a uniform sol solution; (3) according to the lithium titanate and titanate The substance ratio of butyl ester is 11:1. Add lithium titanate powder into titanium oxide sol solution, stir for 48 hours, vacuum filter, and vacuum dry at 150°C for 2 hours to obtain precursor powder; (4) Precursor The bulk powder was reduced in a hydrogen atmosphere furnace at 870°C for 3 hours, cooled to 100°C and released from the furnace to obtain a titanium oxide-coated lithium titanate composite material.

[0019] Using a lithium sheet as the negative electrode, make a button battery in a glove box filled with argon, and do a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com