Controllable topological structure for modularized high-voltage and high-capacity lithium battery pack

A lithium battery pack and topology technology, applied in the field of high-voltage and large-capacity lithium battery pack controllable topology, can solve problems such as unbalanced use, energy imbalance, and battery life decay, so as to improve production yield and reduce screening The effect of requesting and increasing the capacity used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

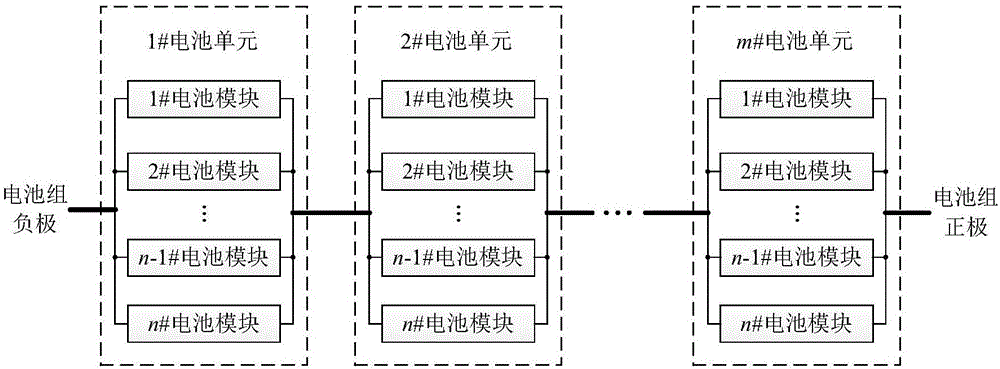

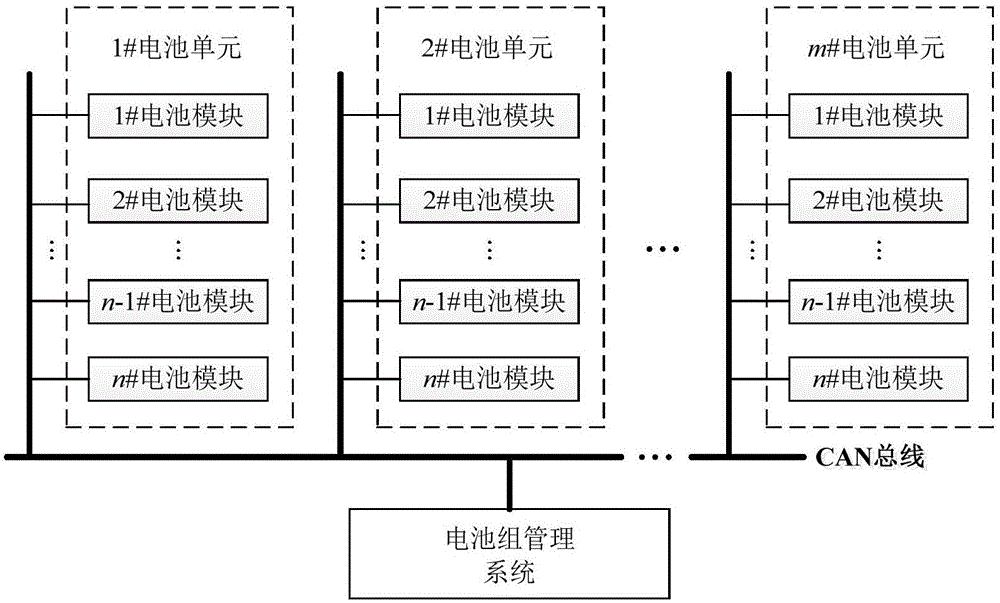

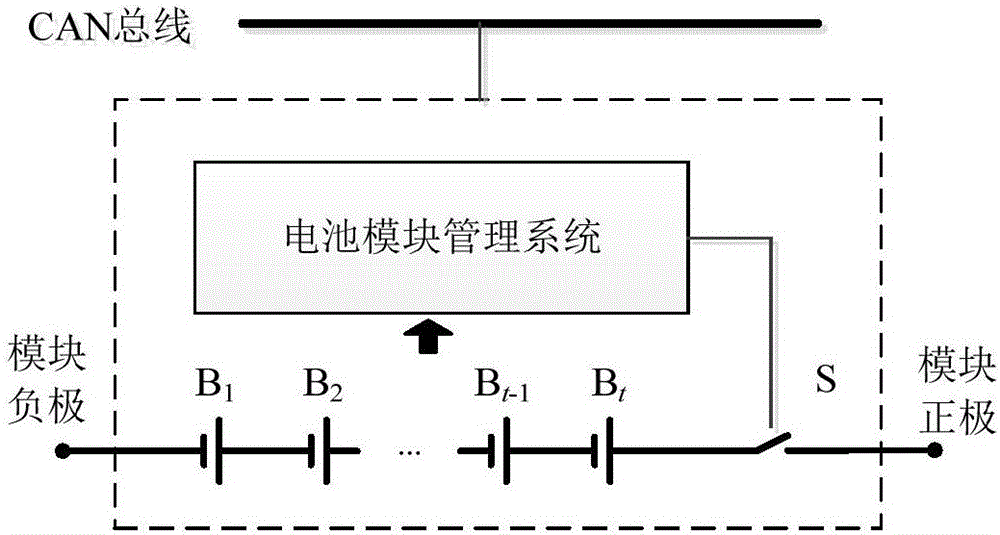

[0037] figure 1 It is a schematic diagram of the lithium battery pack structure and power wiring according to an embodiment of the present invention. Such as figure 1 As shown, the lithium battery pack topology in this embodiment includes m battery units 1# battery unit, 2# battery unit, ..., i# battery unit, ..., m# battery unit, wherein, i, m are Integer, i≤m, i represents any battery unit in 1~m, the internal structure of each battery unit is exactly the same, and the units are connected in series; each battery unit includes n battery modules 1# battery module, 2# battery module ,...,i#battery module,...n#battery unit, where i and n are integers, i≤n, i represents any battery module from 1 to n, each battery module has the same internal structure, and the same unit The modules inside are connected in parallel, and each module is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com