Gradient heating-temperature control method of end-pumped alkali vapor laser

A technology of end-pumping and alkali metal, applied in lasers, laser components, temperature control, etc., can solve problems affecting DPAL quality and light-to-light conversion efficiency, damage to vapor pool end windows, chemical deposition pollution, etc., to improve beam quality , Reduce the probability of damage, the effect of uniform absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

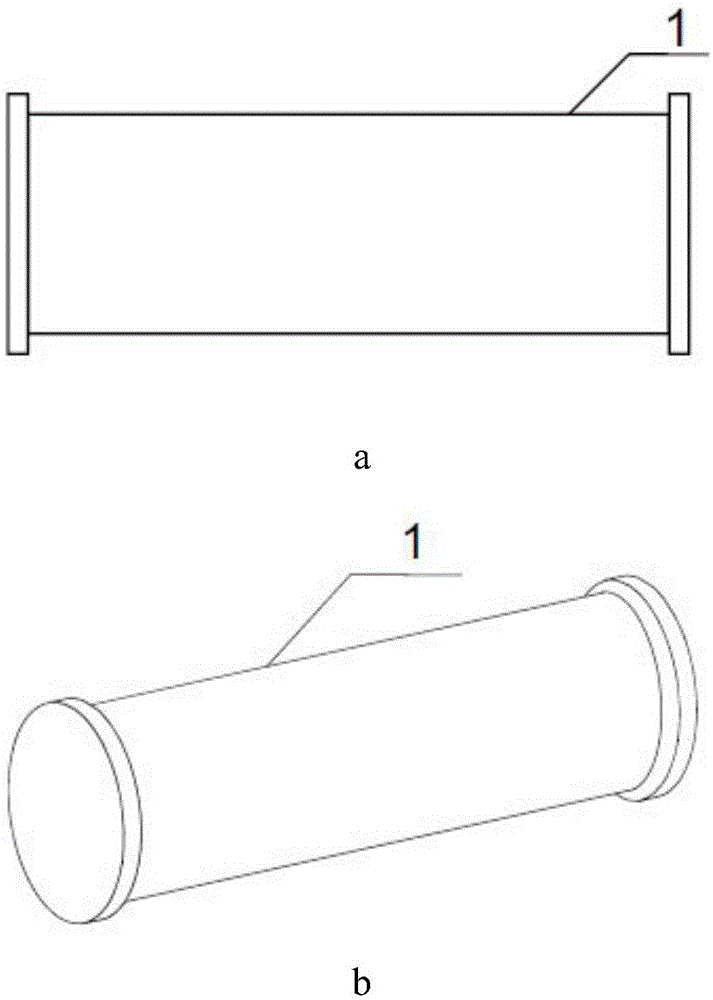

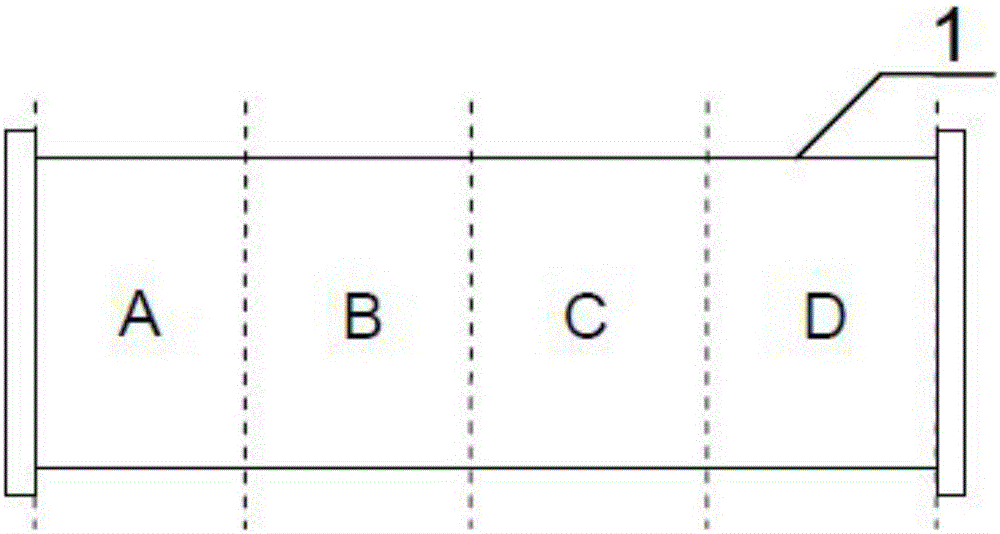

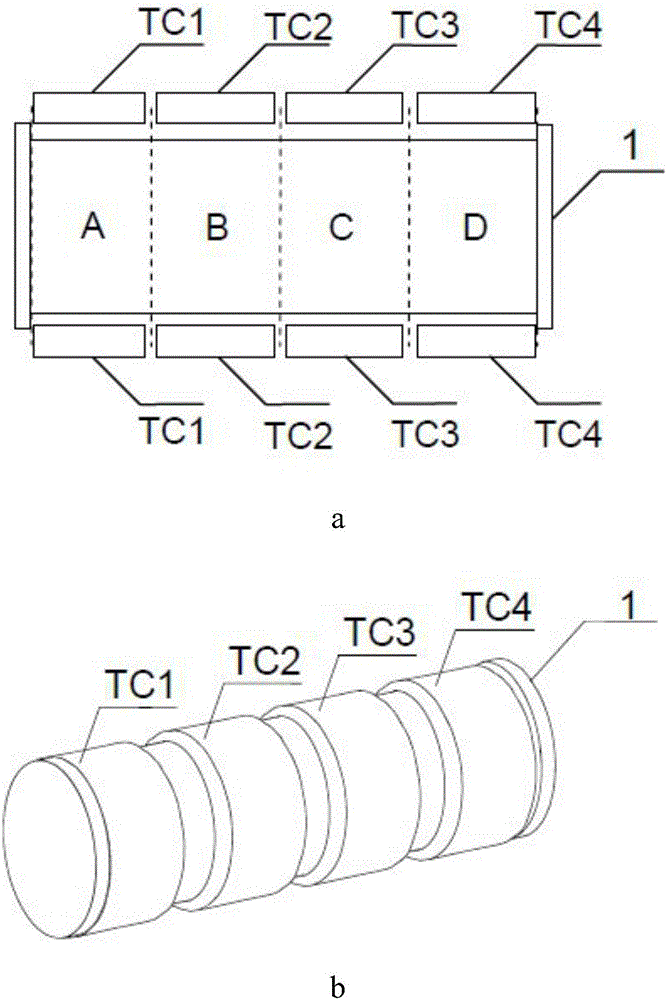

[0027] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] In order to solve the inhomogeneity of the gain distribution in the direction of the optical axis, the reduction of the laser beam quality, the reduction of the light-to-light conversion efficiency and the vapor To solve problems such as damage to the end window of the pool, the present invention provides a gradient heating-temperature control method for an end-pumped alkali metal vapor laser.

[0029] This method takes advantage of the fact that the saturated vapor density of alkali metals is closely dependent on the temperature of the vapor pool, and adjusts the particle number density distribution in the direction of the optical axis in the vapor pool through a non-uniform gradient heating-temperature control m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com