Molten salt method for preparing iron trioxide loaded platinum metal nanometer catalyst in situ

A technology of in-situ preparation and molten salt method, which is used in physical/chemical process catalysts, catalyst activation/preparation, chemical instruments and methods, etc., to achieve low cost raw materials, controllable product particle morphology and crystal structure, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

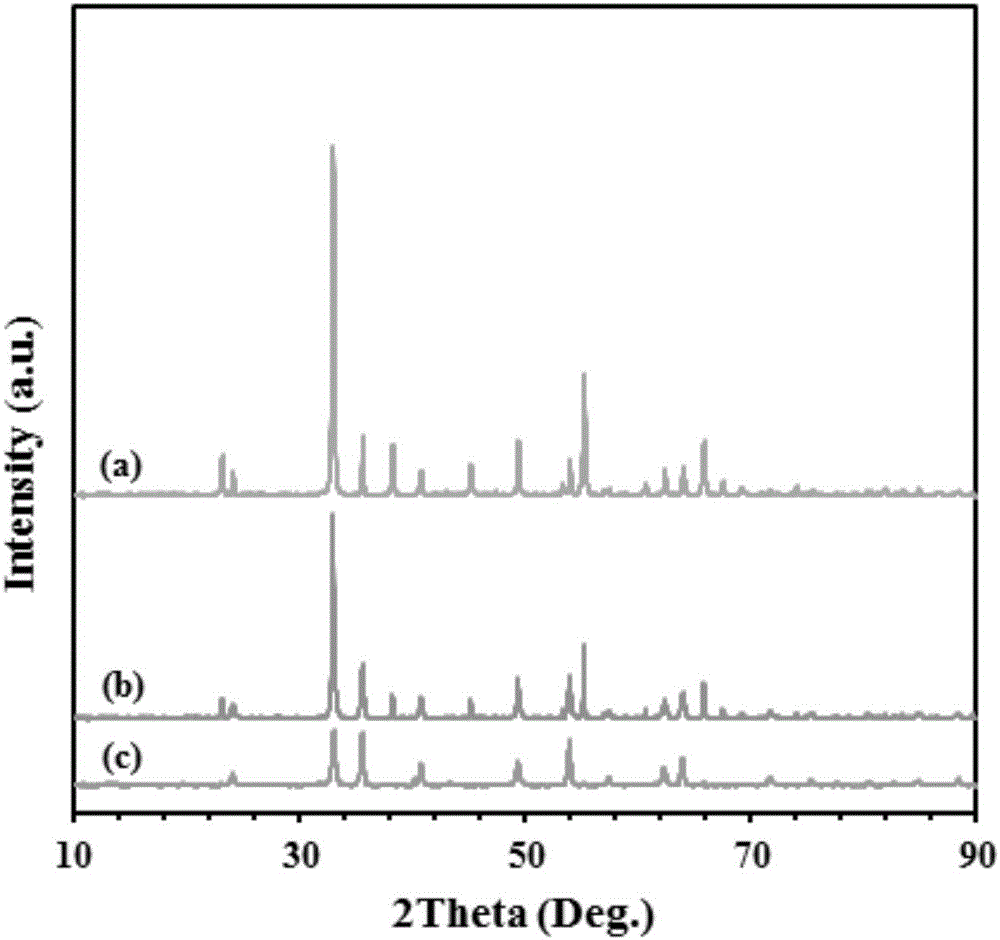

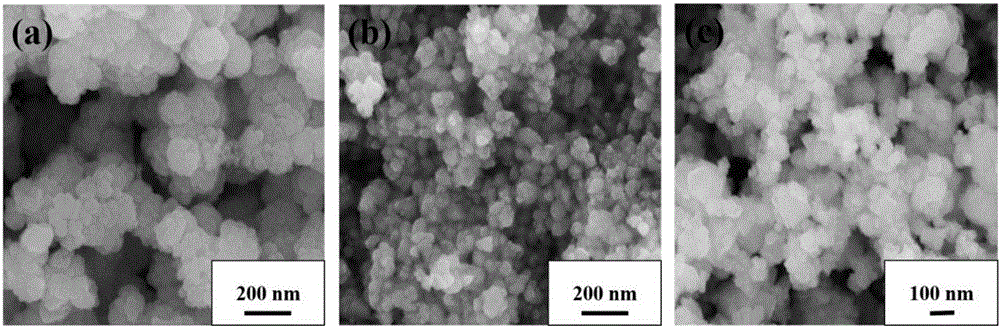

[0012] Example 1: Weigh 0.25g of tetraammine platinum nitrate, put it in a beaker, add 60.5ml of deionized water, stir for 10min to make it evenly mixed, and transfer it to a 200ml brown jar. A tetraammine platinum nitrate solution can be obtained, which is left to stand for use. Weigh NaNO 3 (29.4g), NaF (0.6g), Fe 2 (SO 4 ) 3 (2.0g) was placed in a 100ml crucible, and 1.031ml of the tetraammineplatinum nitrate solution prepared above was taken, added dropwise into the crucible, and dried in an oven at 80°C. After complete drying, ball mill in a ball mill for 20 minutes to mix evenly, then transfer to a muffle furnace for roasting, rise from room temperature to 350 °C at a rate of 3 °C / min, keep warm for 3 hours, cool naturally to room temperature, and dissolve , suction filtration, washing, and drying, a nanocatalyst with a theoretical noble metal loading of 0.5% can be prepared, that is, 0.5% Pt / Fe 2 o 3 nanocatalyst.

Embodiment 2

[0013] Embodiment 2: take by weighing NaNO 3 (29.4g), NaF (0.6g), Fe 2 (NO 3 ) 3 (2.0g) was placed in a 100ml crucible, and 1.021ml of tetraammine platinum nitrate solution prepared in Example 1 above was taken, added dropwise to the crucible, and dried in an oven at 80°C. After complete drying, ball mill in a ball mill for 20 minutes to mix evenly, then transfer to a muffle furnace for roasting, rise from room temperature to 350 °C at a rate of 3 °C / min, keep warm for 3 hours, cool naturally to room temperature, and dissolve , suction filtration, washing, and drying, a nanocatalyst with a theoretical noble metal loading of 0.5% can be prepared, that is, 0.5% Pt / Fe 2 o 3 nanocatalyst.

Embodiment 3

[0014] Embodiment 3: take by weighing NaNO 3 (29.4g), NaF (0.6g), FeCl 3 (2.0g) was placed in a 100ml crucible, and 1.527ml of the tetraammine platinum nitrate solution prepared in Example 1 above was taken, added dropwise to the crucible, and dried in an oven at 80°C. After complete drying, ball mill in a ball mill for 20 minutes to mix evenly, then transfer to a muffle furnace for roasting, rise from room temperature to 350 °C at a rate of 3 °C / min, keep warm for 3 hours, cool naturally to room temperature, and dissolve , suction filtration, washing, and drying, a nanocatalyst with a theoretical noble metal loading of 0.5% can be prepared, that is, 0.5% Pt / Fe 2 o 3 nanocatalyst.

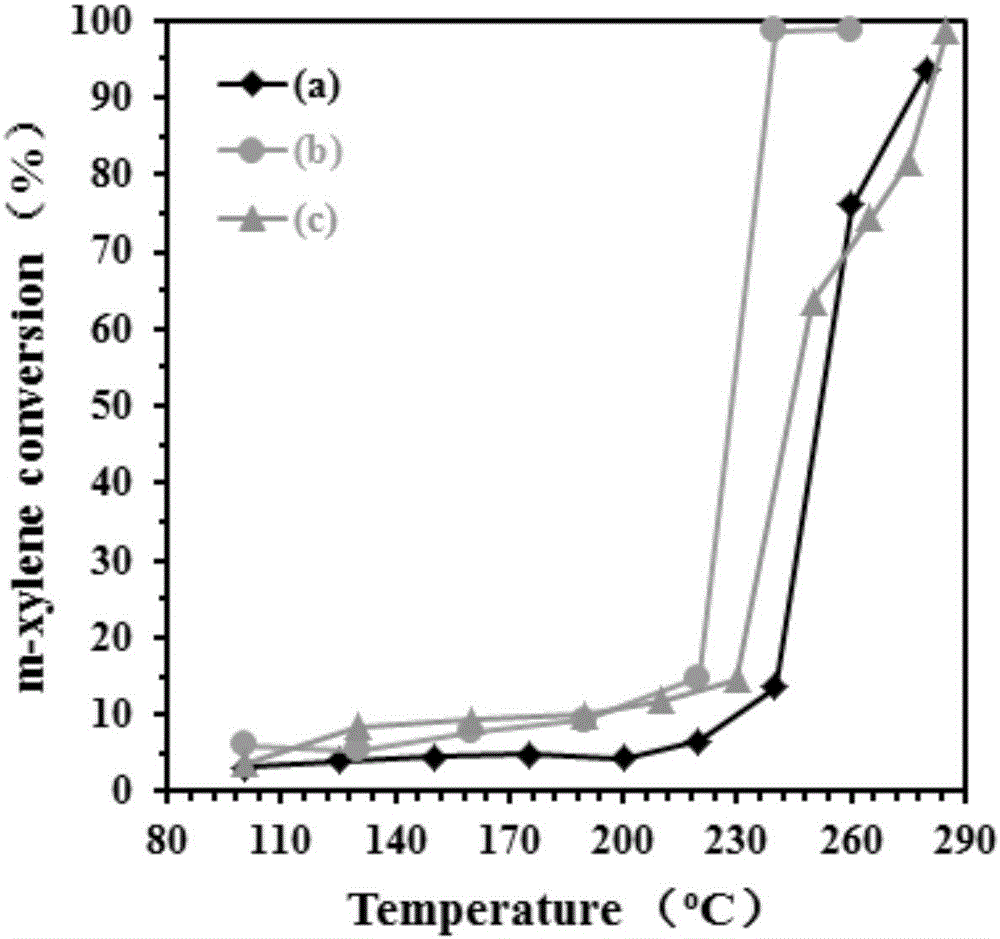

[0015] The preparation method of the present invention is novel, the raw material is cheap, the preparation process is simple, the particle shape of the product is controllable, and the yield is high. The obtained Pt / Fe 2 o 3 Nanomaterials have good catalytic properties for xylene oxidation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com