A hydrogen peroxide synergistic biochemical treatment method simulating pva-containing printing and dyeing wastewater

A printing and dyeing wastewater and biochemical treatment technology, which is applied in textile industry wastewater treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem that wastewater is difficult to achieve the treatment effect, and the biochemical requirements of wastewater are high and difficult Large-scale application and other issues to achieve the effect of improving biochemical treatment efficiency, reducing pressure, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

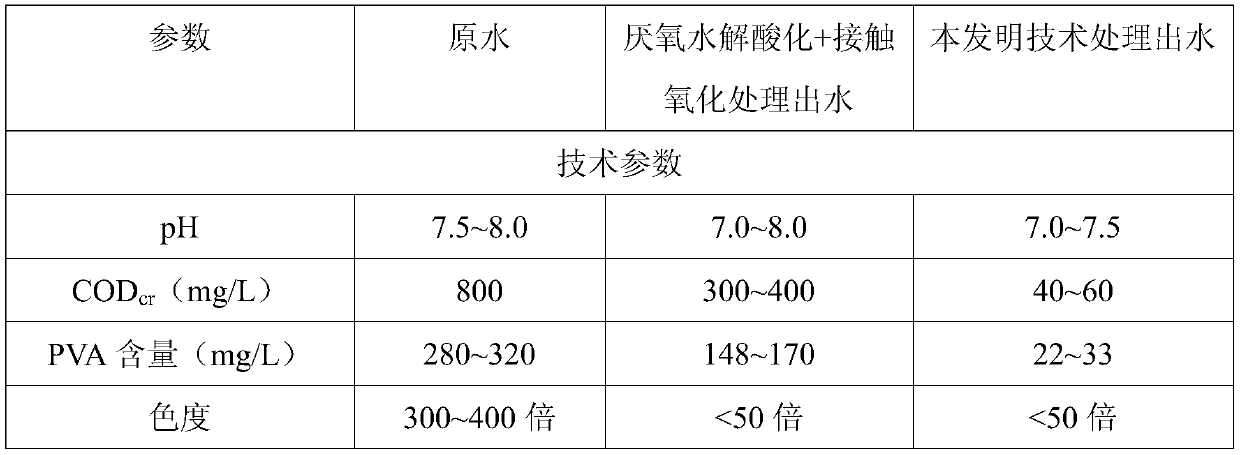

[0032] According to survey statistics, the PVA content in the actual desizing wastewater is about 1-5g / L, and this wastewater accounts for 5%-15% of the comprehensive printing and dyeing wastewater, that is, the average PVA content in the comprehensive printing and dyeing wastewater is 300mg / L, while in the actual printing and dyeing industry There are many kinds of dyes, but more than 50% are azo dyes. In addition, the actual printing and dyeing wastewater is generally alkaline, and the pH value generally does not exceed 11. Based on the above factors, configure simulated printing and dyeing wastewater with a PVA content of 280-320 mg / L, an overall COD concentration of 800 mg / L, a B / C ratio of 0.2-0.23, a pH value of 7.5-8.0, and an azo dye reactive black B150 content of 8 mg / L. L, chroma 300-400 times.

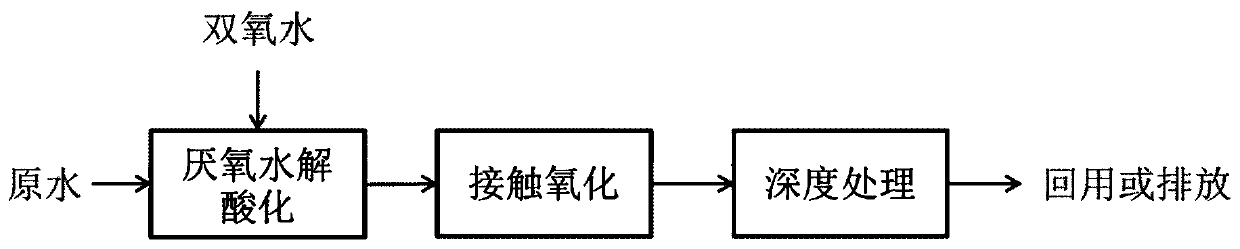

[0033] The present invention uses hydrogen peroxide to synergistically biochemically treat the simulated printing and dyeing wastewater containing PVA, and its technological...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com