Treatment method and treatment apparatus for oil filed produced water

A treatment method and technology of produced water, which is applied in the fields of mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of backward produced water treatment technology, achieve good water production effect and reduce operating costs Low, stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

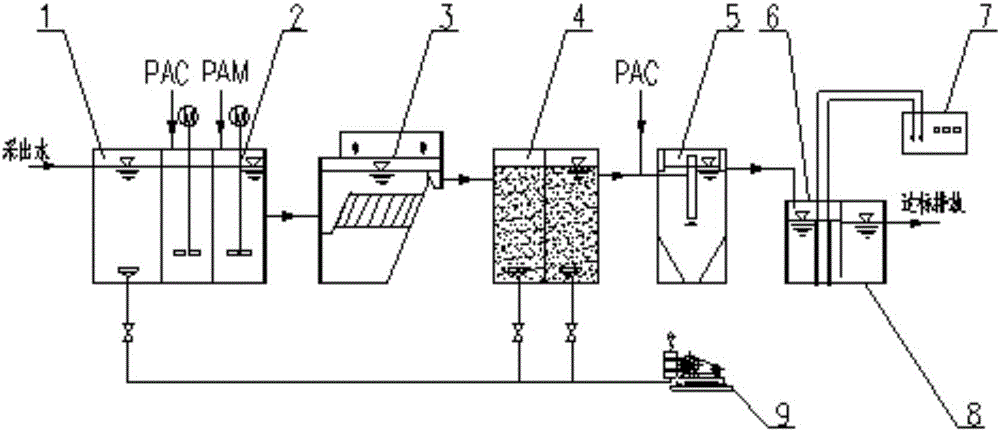

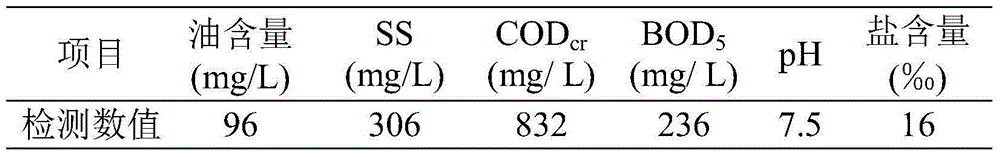

[0046] Example 1: Retrieve the activated sludge from the sedimentation tank of Station No. 72 of the No. 2 Oil Production Plant of Xinjiang Oilfield, and carry out film acclimation. After the system runs stably, a continuous experiment is carried out with produced water, with a treatment capacity of 1m 3 / hr. Air oxidation hydraulic retention time 2hr, coagulation tank PAC dosage 700mg / L, PAM dosage 1.5mg / L, multiphase air flotation hydraulic retention time 45min, vertical flow sedimentation tank PAC dosage 60mg / L, hydraulic retention The time is 1.5hr, the electrocatalytic oxidation current is 450A, and the hydraulic retention time is 50min. The experimental results are shown in Table 2, and the removal rate of the system is shown in Table 3.

[0047] Table 2 system process effluent water quality

[0048]

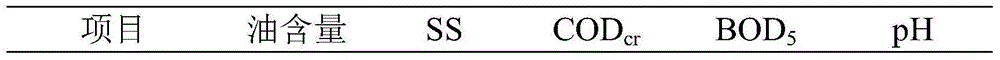

[0049]

[0050] It can be seen from the experimental results in Table 2 that all the oil was removed, the removal rate of suspended solids reached 99.3%, and the CO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com