A method for preparing low-viscosity eva emulsion by controlling stirring rate

A stirring speed, low viscosity technology, applied in the field of preparation of low viscosity EVA emulsion, can solve the problems of poor particle shape and emulsion stability, limited application range, difficult storage of products, etc., to maintain particle shape and toughness strength, reduce system viscosity , the effect of reducing the number of micelles in the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

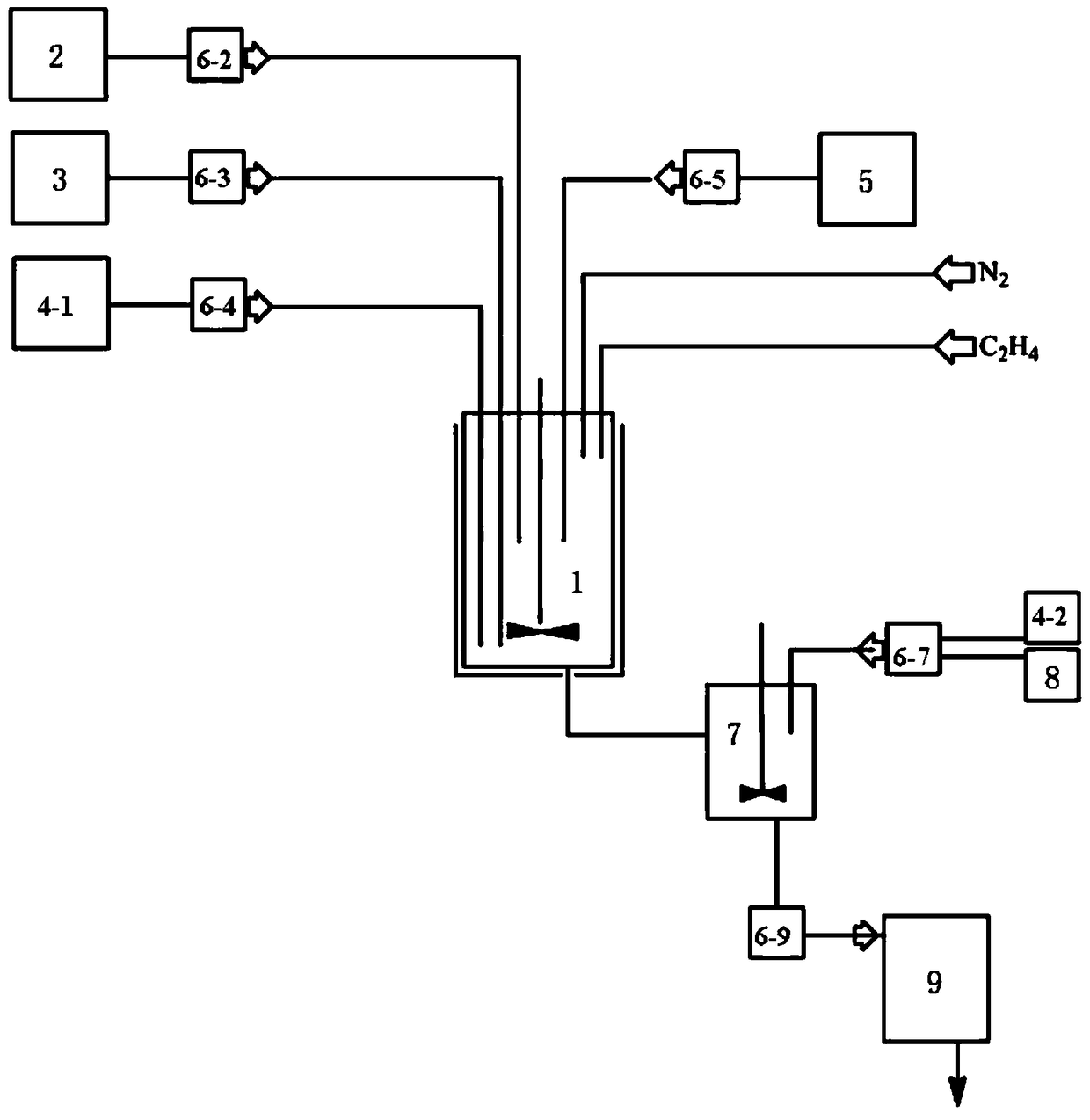

[0030] like figure 1 The shown copolymerization reaction device for the preparation of low-viscosity EVA emulsion. A single-pot batch operation is adopted, including a copolymerization reactor 1, a feeding mechanism and a product post-treatment part. Described copolymerization reactor 1 top is provided with emulsifier / colloid protective agent feed inlet, initiator feed inlet, pH value adjuster feed inlet and vinyl acetate liquid phase feed inlet, and N 2and ethylene feed port. The emulsifier / colloid protective agent tank 2 is communicated with the copolymerization reactor 1 through the high-pressure metering pump 6-2, the initiator tank 3 is communicated with the copolymerization reactor 1 through the high-pressure metering pump 6-3, and the pH value regulator tank 4-1 is communicated with the copolymerization reactor 1 through the high-pressure metering pump 6-3. The metering pump 6-4 communicates with the copolymerization reactor 1, and the VAc monomer tank 5 communicates ...

Embodiment 1

[0035] Using ammonium persulfate as initiator, the consumption is 0.3wt% of vinyl acetate; O / W system, the dosage of surfactant op-10 is 10.0wt% of the dosage of VAc monomer; the dosage of colloid protective agent PVA is the dosage of VAc monomer 3.0wt% of VAc; pH regulator sodium bicarbonate dosage is 0.5wt% of VAc monomer dosage; polymerization reaction temperature is 80 DEG C, ethylene reaction pressure is 75.0MPa, and the pH value of the reaction process is controlled at 6.5. The stirring speed in the pre-emulsification stage was 40r / min, the stirring speed in the polymerization stage was 80r / min, and the polymerization reaction time was 4.5h. Under these conditions, the content of VAc in the polymerization product was 61.9wt%, the viscosity of the emulsion was 146mpa.s, the stability of the emulsion was good, and the emulsion could be stored stably for 6 months.

Embodiment 2

[0037] Using ammonium persulfate as initiator, the consumption is 0.3wt% of vinyl acetate; O / W system, the dosage of surfactant op-10 is 10.0wt% of the dosage of VAc monomer; the dosage of colloid protective agent PVA is the dosage of VAc monomer 3.0wt% of VAc; pH regulator sodium bicarbonate dosage is 0.5wt% of VAc monomer dosage; polymerization reaction temperature is 80 DEG C, ethylene reaction pressure is 75.0MPa, and the pH value of the reaction process is controlled at 6.5. The stirring speed in the pre-emulsification stage was 45r / min, the stirring speed in the polymerization stage was 85r / min, and the polymerization reaction time was 4.5h. Under these conditions, the content of VAc in the polymerization product is 61.8wt%, the viscosity of the emulsion is 120mpa.s, the stability of the emulsion is good, and the emulsion can be stored stably for 7 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com