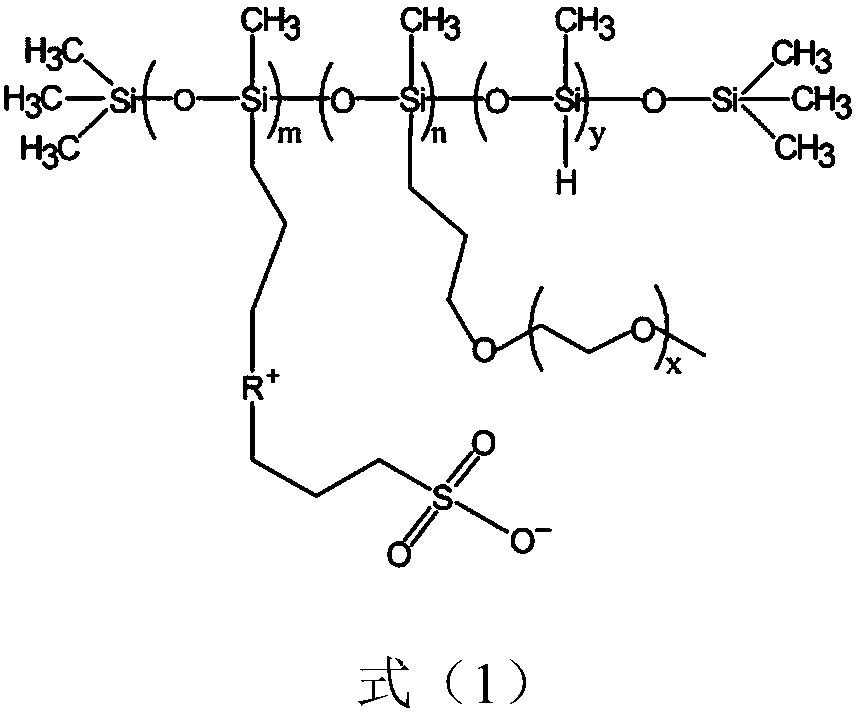

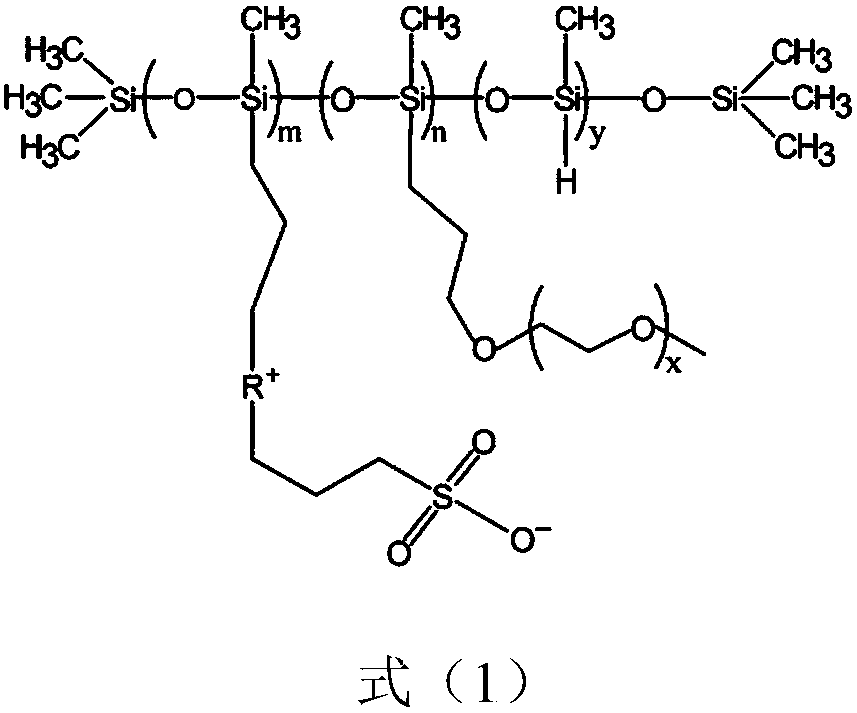

A kind of electrolyte membrane containing zwitterionic all-solid polymer and its preparation method and application

An all-solid polymer and amphoteric ion technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, electrolyte immobilization/gelation, etc., can solve the problems of low room temperature conductivity and low electrochemical window, and achieve the reduction of glass Change transition temperature, reduce crystallinity, and solve the safety problems of electrolyte leakage and decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The synthesis of embodiment example 1 polyether modified polysiloxane

[0026] Weigh a certain amount of polymethylhydrogensiloxane (PMHS), mix it with an appropriate amount of toluene and add it to a 50ml three-necked flask, move it to an oil bath for heating, and add an appropriate amount of allyl-terminated polyether (PEO) (m (PEO) :m (PMHS) =2), an appropriate amount of Speier catalyst is uniformly dispersed in toluene solvent and then added in the normal pressure funnel, under N 2 Under the atmosphere, the mixed solution in the normal pressure funnel was dropped into the three-necked flask drop by drop, first reacted at 50°C for a certain period of time, then heated to 80°C for a certain period of time, until the PEO reaction was complete, the product was washed with n-hexane to remove impurities, and spin The solvent was distilled off to obtain a polyether-modified polysiloxane (PEO-g-PMHS).

Embodiment 2

[0027] The preparation of implementation example 2 polymer lithium ion batteries

[0028] (1) Place the polyether-modified polysiloxane prepared in Example 1 in a 100ml round-bottomed flask, then add an appropriate amount of crosslinking agent and lithium bistrifluoromethylsulfonimide (LiTFSI), add lithium salt The amount satisfies [EO]:[Li + ]=20:1, fully stirred in acetonitrile solvent, and mixed evenly.

[0029] (2) Pour the mixed solution in (1) into a polytetrafluoroethylene mold, then place it in a vacuum oven, and dry it in vacuum to obtain an all-solid modified polymer electrolyte membrane.

[0030] (3) The positive electrode, the all-solid polymer electrolyte membrane and the negative electrode are stacked together, sealed in a button battery or aluminum-plastic composite packaging film, and compressed into an all-solid polymer lithium-ion battery.

Embodiment 3

[0031] The preparation of implementation example 3 polymer lithium ion batteries

[0032] (1) Weigh a certain amount of polymethylhydrogensiloxane (PMHS), mix it with an appropriate amount of toluene, add it to a 50ml three-necked flask, move it to an oil bath for heating, and mix allyl-terminated polyether (PEO) ( m (PEO) :m (PMHS) =2), N,N-dimethylallylamine (DMAA) (n (DMAA) :n (PEO) =1:20) and an appropriate amount of Speier catalyst are mixed uniformly in toluene and then added to the normal pressure funnel, followed by N 2 Under the atmosphere, the mixed solution in the normal pressure funnel was dropped into the three-necked flask drop by drop, first reacted at 50°C for a certain period of time, and then heated to 80°C for a certain period of time, the mixed solution changed from colorless and transparent to a light yellow transparent solution, and the product passed through Washing with n-hexane to remove impurities, rotary evaporation to obtain grafted DMAA and PEO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com