Reflective insulation coating and preparing method thereof

A technology for reflective and heat-insulating coatings and raw materials, which is applied in reflective/signal coatings, anti-corrosion coatings, fire-retardant coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

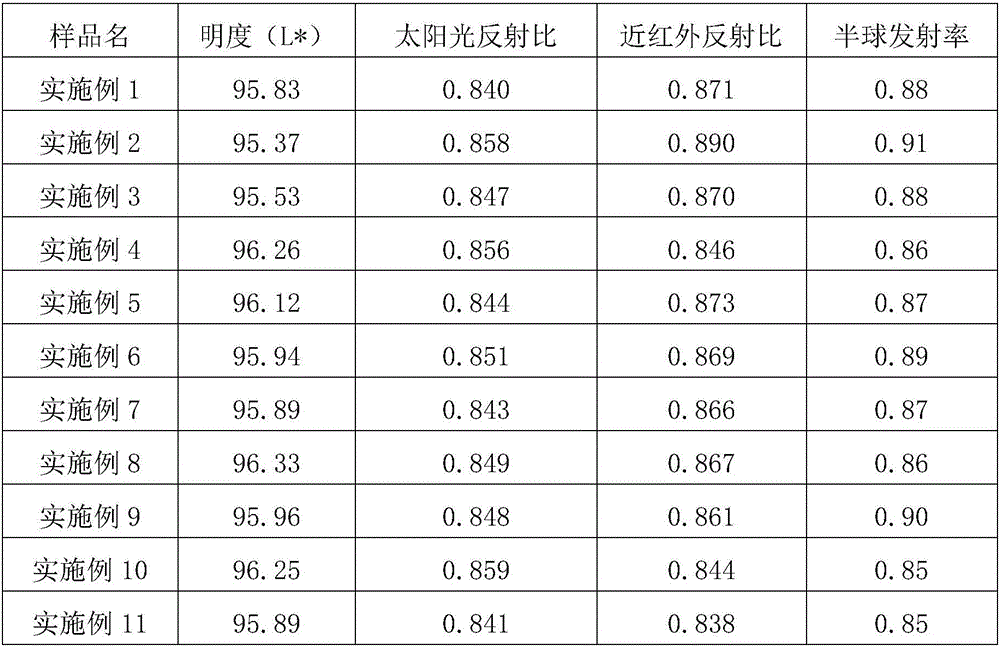

Examples

Embodiment 1

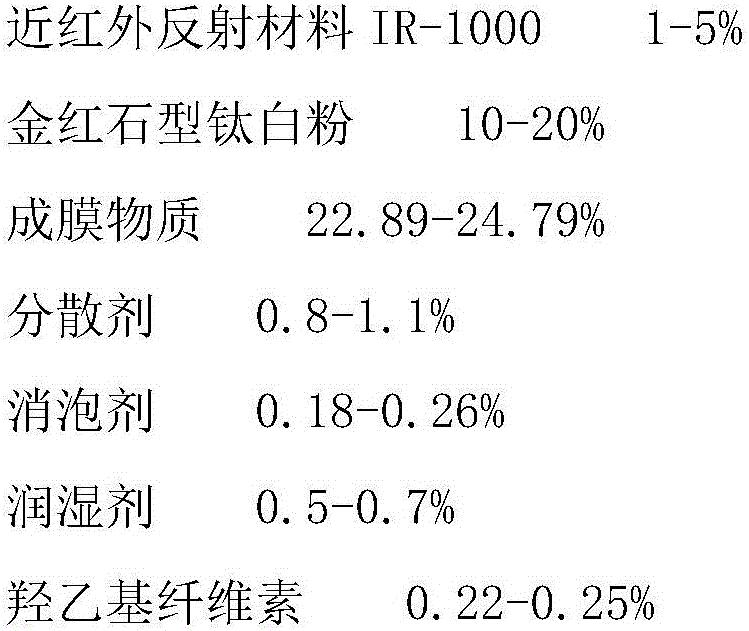

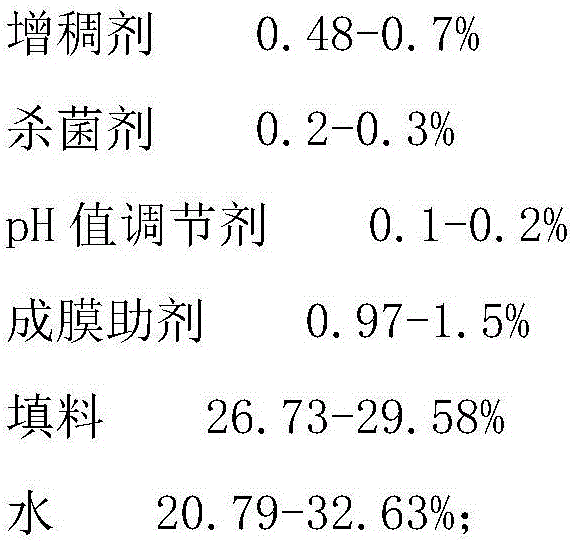

[0042] Embodiment 1: a kind of reflective heat-insulating coating, it comprises the raw material of following mass percent:

[0043] Near-infrared reflective material IR-1000 is 4%, rutile titanium dioxide is 11%, silicone acrylic emulsion RC-3677 is 22.89%, dispersant 5040 is 0.8%, defoamer NXZ is 0.18%, wetting agent PE-100 0.5% for hydroxyethylcellulose TA 3000, 0.22% for hydroxyethylcellulose TA 3000, 0.7% for thickener DSX 3551, 0.2% for fungicide 253, 0.2% for pH regulator HY-95, and 0.97% for film-forming aid EFC 300 %, talcum powder is 3.5%, kaolin is 3.47%, light calcium carbonate is 12.34%, heavy calcium carbonate is 10.27%, and water is 28.76%.

[0044] The preparation method of the reflective heat-insulating paint of embodiment 1, comprises the following steps:

[0045] Step (1): prepare the raw material of mass percent in embodiment 1; Be that the defoamer NXZ of 0.18% by mass percent is divided into two parts of 0.04% and 0.14%, divide the moisture of 28.76% by ...

Embodiment 2

[0050] Embodiment 2: a kind of reflective insulation coating, it comprises the raw material of following mass percent:

[0051] Near-infrared reflective material IR-1000 is 5%, rutile titanium dioxide is 10%, pure acrylic emulsion XY-208C is 24.79%, dispersant 5040 is 1.1%, defoamer Foamstar 309A is 0.26%, wetting agent Disponer W-20 is 0.7%, hydroxyethyl cellulose HS30000YP2 is 0.25%, thickener SN 636 is 0.48%, fungicide DGOS QB20 is 0.3%, pH regulator AMP-95 is 0.1%, film-forming aid EFC 300 is 1.5%, talc is 3.21%, kaolin is 2.86%, light calcium carbonate is 11.78%, heavy calcium carbonate is 8.88%, and water is 28.79%.

[0052] The preparation method of the reflective heat-insulating paint of embodiment 2, comprises the following steps:

[0053] Step (1): prepare the raw material of the mass percent among the embodiment 2; Be that the defoamer Foamstar 309A of 0.26% is divided into two parts of 0.08% and 0.18% by mass percent, be that the moisture of 28.79% is divided into...

Embodiment 3

[0058] Embodiment 3: a kind of reflective heat-insulating coating, it comprises the raw material of following mass percent:

[0059] Near-infrared reflective material IR-1000 is 3%, rutile titanium dioxide is 12%, styrene-acrylic emulsion TL-668 is 23.08%, dispersant 5040 is 1%, defoamer NEX is 0.21%, wetting agent PE-100 0.65% for hydroxyethylcellulose TA3000, 0.23% for hydroxyethylcellulose TA3000, 0.6% for thickener SN-636, 0.28% for fungicide 253, 0.15% for pH regulator C-950, and 1.3% for film-forming aid EFC 300 %, talcum powder is 3.31%, kaolin is 2.97%, light calcium carbonate is 11.87%, heavy calcium carbonate is 9.86%, and water is 29.49%.

[0060] The preparation method of the reflective heat-insulating coating of embodiment 3, comprises the following steps:

[0061] Step (1): prepare the raw material of the mass percent in embodiment 3; Be that the defoamer NXZ of 0.21% by mass is divided into two parts of 0.05% and 0.16%, divide the moisture of 29.49% by mass int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com