Super-hydrophobic material and preparation method thereof

A technology of super-hydrophobicity and coating additives, applied in the direction of coating, can solve the problems of complex process and difficult processing, and achieve the effect of simple process, strong operability and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

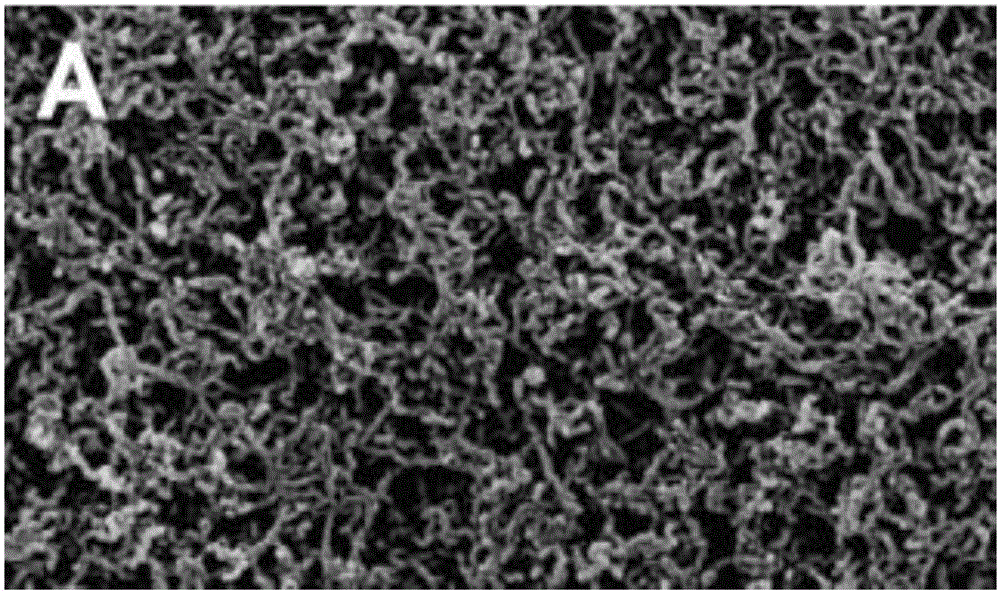

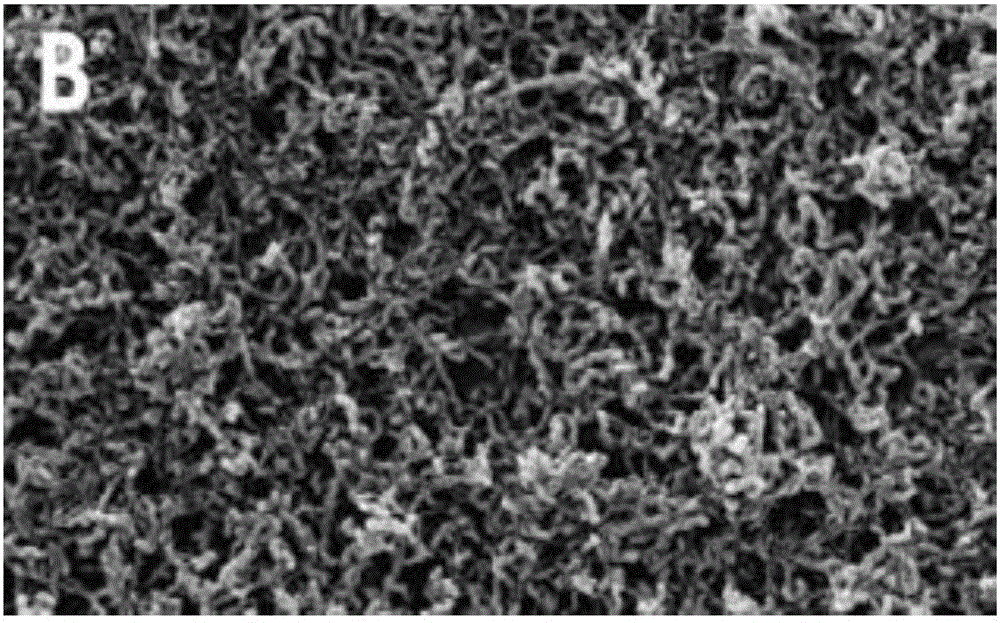

Image

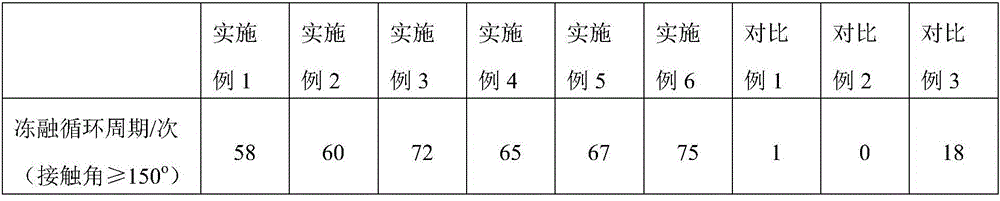

Examples

Embodiment 1

[0035] Embodiment 1 Preparation of superhydrophobic material of the present invention

[0036] 100g cyclohexane, 2.5g nano-silica (15nm), 2.5g nano-silica (50nm), 1g thermoplastic elastomer SBS, 0.05g compatibilizer AIBN, 0.1g antioxidant 1010, 0.1g light stabilizer Agent 770, mixed to form a solution, ultrasonicated in a 50W ultrasonic wave for 30 minutes, to obtain a coating solution.

[0037] Use a 10 μm coater to coat the surface of the aluminum alloy, treat it at 20°C and a humidity of 40% for 3 hours, and cure it in a vacuum oven at 80°C for 2 hours to obtain the superhydrophobic material of the present invention.

Embodiment 2

[0038] Embodiment 2 Preparation of superhydrophobic material of the present invention

[0039] With 2g absolute ethanol, 98g cyclohexane, 5g nano-silica (15nm), 20g nano-silica (50nm), 30g thermoplastic elastomer SBS, 3g compatibilizer DCP, 0.6g antioxidant 1330, 0.6g The light stabilizer 234 was mixed to form a solution, which was ultrasonicated in a 200W ultrasonic wave for 60 minutes to obtain a coating solution.

[0040] Use a 250 μm coater to coat the surface of the aluminum alloy, treat it at 35° C. and a humidity of 80% for 8 hours, and cure it in a vacuum oven at 140° C. for 8 hours to obtain the superhydrophobic material of the present invention.

Embodiment 3

[0041] Embodiment 3 Preparation of superhydrophobic material of the present invention

[0042] With 50g cyclohexane, 50 parts of toluene, 10g nano-silica (100nm), 15g nano-silica (300nm), 15g thermoplastic elastomer SBS, 1.5g compatibilizer BPO, 0.3g antioxidant 168, 0.3g Light stabilizer 770, mixed to form a solution, ultrasonicated in a 100W ultrasonic wave for 45 minutes, to obtain a coating solution.

[0043] Use a 100 μm coater to coat the surface of the aluminum alloy, treat it at 30°C and a humidity of 60% for 6 hours, and cure it in a vacuum oven at 120°C for 6 hours to obtain the superhydrophobic material of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com