A kind of superhydrophobic fiber material and preparation method thereof

A fiber material and super-hydrophobic technology, applied in fiber treatment, liquid-repellent fibers, textiles and papermaking, etc., can solve problems such as difficult to reuse, complex preparation process, etc., and achieve the goal of changing the surface charge and reducing the surface energy of the material Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

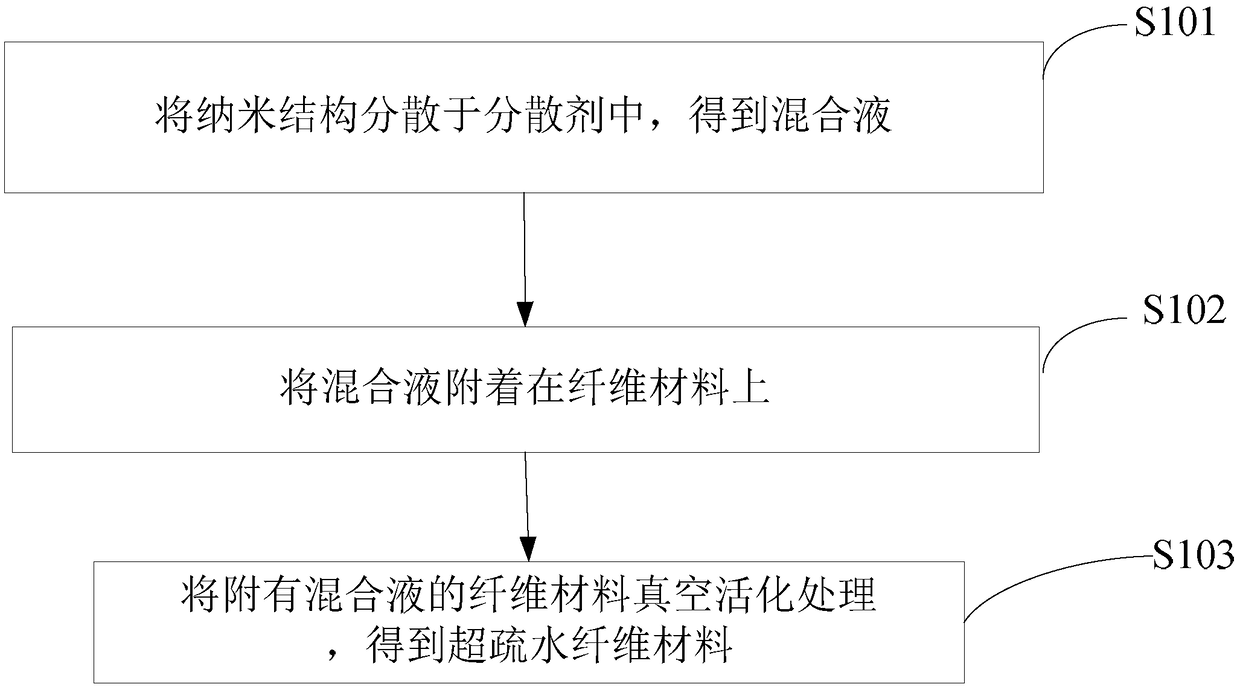

[0022] see figure 1 , the invention provides a kind of preparation method of superhydrophobic fiber material, comprises the steps:

[0023] Step S101, dispersing the nanomaterial in the dispersant to obtain a mixed solution;

[0024] Step S102, attaching the mixed solution to the fiber material;

[0025] Step S103, vacuum-activating the fiber material with the mixed solution to obtain the superhydrophobic fiber material, wherein the surface of the superhydrophobic fiber material is a superhydrophobic structure composed of nanomaterials, and the nanomaterial and fiber Materials are connected by van der Waals forces.

[0026] In step S101, the nanomaterials are dispersed in a dispersant to achieve uniform dispersion. It can be understood that the dispersing means can be stirring or ultrasound. The dispersant can be at least one of ethanol, methanol, ethylene glycol, acetone, and water. The dispersant is preferably a volatile solvent, such as ethanol, methanol, ethylene glyc...

Embodiment 1

[0042] Disperse 10 mg of titanium dioxide nanoparticles in 20 mL of a mixed solution of ethanol and water mixed in any volume ratio to obtain a mixed solution;

[0043] Attaching the mixed solution to the polyester fiber material;

[0044] The fiber material attached with the mixed liquid is vacuum activated to obtain the superhydrophobic fiber material. The temperature of the vacuum activation treatment is 180 degrees Celsius.

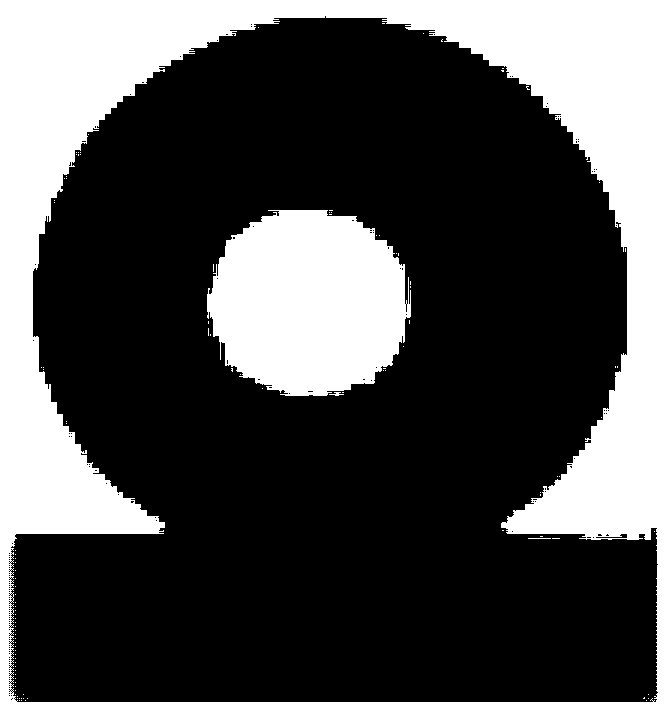

[0045] The obtained superhydrophobic fiber material was subjected to a hydrophobic experiment, and the result showed that the contact angle between the superhydrophobic fiber material and water was 160 degrees.

Embodiment 2

[0047] Disperse 10 mg of tellurium and carbon composite nanorods in 20 mL of a mixed solution of ethanol and water mixed in any volume ratio to obtain a mixed solution;

[0048] The mixed solution is attached to the polyamide fiber material;

[0049] The fiber material attached with the mixed liquid is vacuum activated to obtain the superhydrophobic fiber material. The temperature of the vacuum activation treatment is 200 degrees Celsius.

[0050] The obtained superhydrophobic fiber material was subjected to a hydrophobic experiment, and the result showed that the contact angle between the superhydrophobic fiber material and water was 160 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com