Formation method of fin field effect transistor

A fin field effect tube and fin technology, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems that the electrical performance of the fin field effect tube needs to be improved, so as to improve the anti-penetration effect, avoid injection damage, electrical The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

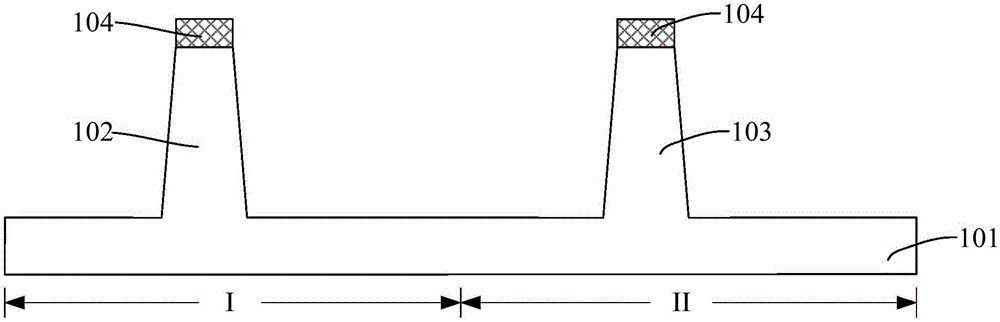

[0020] It can be seen from the background art that the electrical performance of the fin field effect transistor formed in the prior art needs to be improved.

[0021]It has been found through research that the distance between the bottom of the fin and the gate structure of the fin field effect transistor is relatively long, the ability of the gate structure to control the bottom of the fin is weak, and the doping concentration of the fin is small, and the channel The space charge region of the area is widened under the electric field, and the space charge region of the source region and the drain region are connected, resulting in a punch through phenomenon between the source region and the drain region at the bottom of the fin field effect transistor, resulting in a fin field effect The electrical performance of the tube is low.

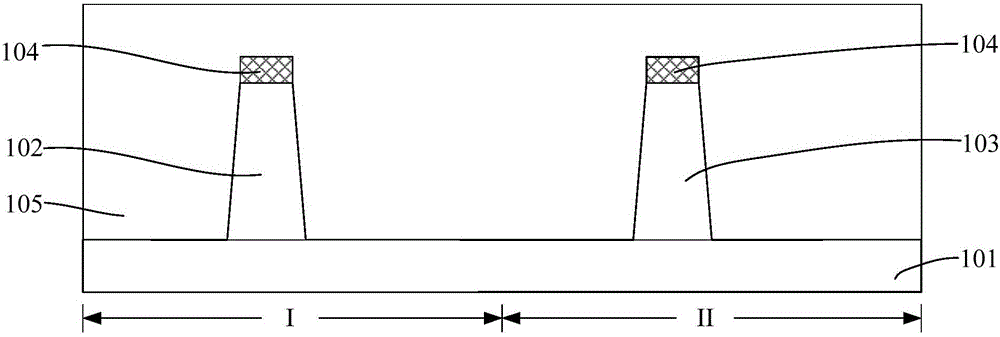

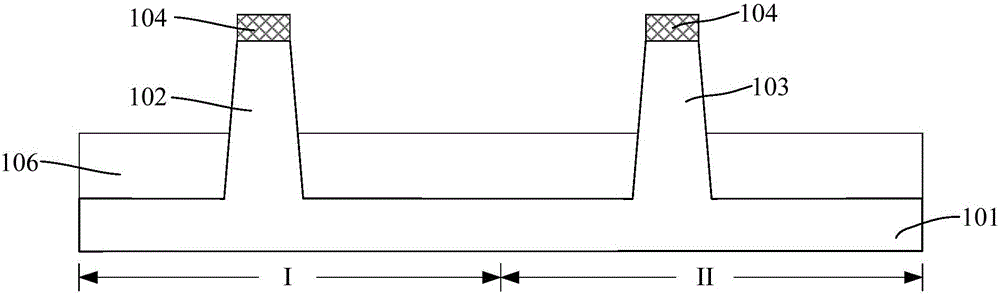

[0022] In order to prevent the punch-through phenomenon, a solution is proposed: forming an anti- punch-through layer at the bottom of the fin. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com