Bootstrap diode structure based on P-type substrate and manufacturing process

A diode and substrate technology, applied in the field of semiconductor device structure and its manufacturing process, can solve the problems of increasing peripheral circuit connection, destroying circuit timing, increasing chip cost, etc., and achieving improved reliability, low cost and process difficulty, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

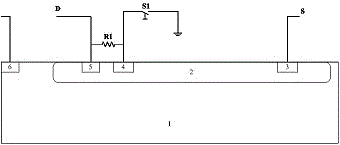

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] Such as image 3 As shown, the integrated circuit structure of the present invention includes a P-type lightly doped substrate 1; an N well region 2; 3 and 5 are N+ regions; 4 and 6 are P+ regions. 4 and 5 are connected through resistor R1, and 4 is connected with GND through switch S1. The switch of S1 is realized by the control signal; 6 is generally connected to the ground or the common terminal; 5, 4, 3, and 2 form a JFET, 5 is the drain terminal, 2 is the channel, 4 is the gate, and 3 is the source terminal ;

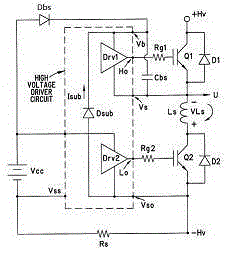

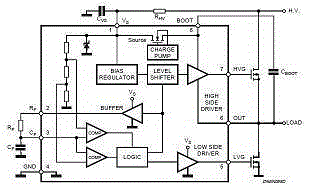

[0022] This structure is equivalent to a bootstrap diode and can replace figure 1 The function of Dbs in Dbs, where the D terminal (5) is connected to the positive pole of Vcc, and the S terminal (3) is connected to the upper plate of Vb and Cbs; it can also replace figure 2 The charge pump in and the connected MOSFET;

[0023] Realization function ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com