Polycaprolactone-graphene oxide composite porous scaffold material preparation method

A graphene composite, polycaprolactone technology, applied in medical science, tissue regeneration, prosthesis, etc., can solve the problems of lack of biorecognizable sites, poor hydrophilicity, low mineralization activity, etc., to improve osteogenesis Cytocompatibility and osteogenic activity, high porosity, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

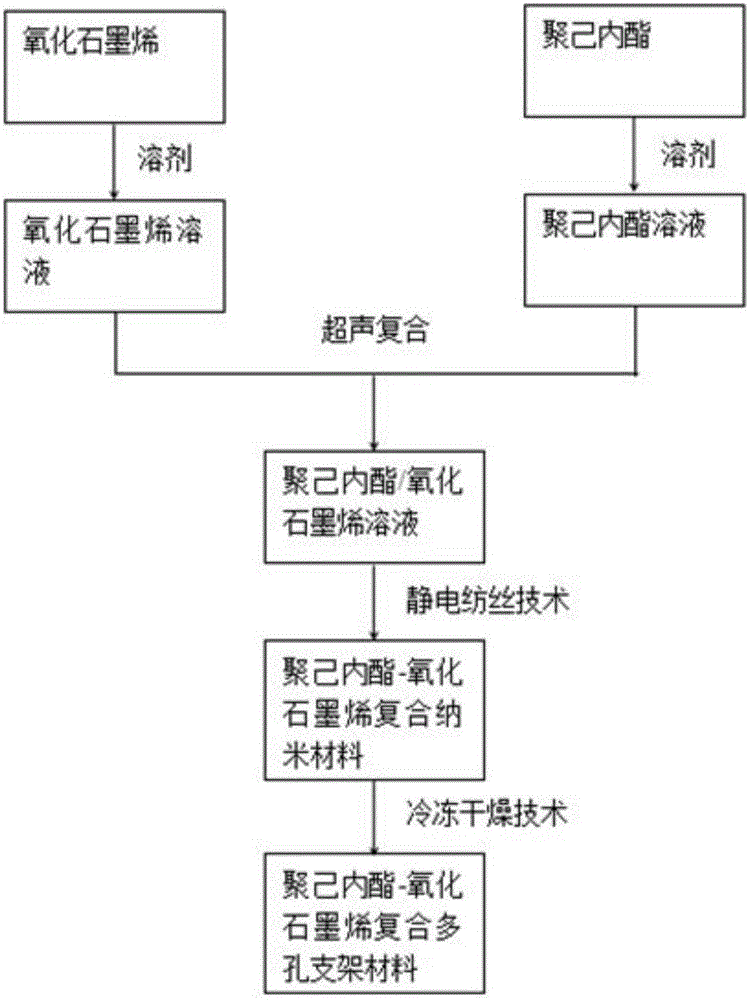

[0013] A preparation method of a polycaprolactone-graphene oxide composite porous scaffold material, the preparation method comprising the following steps:

[0014] (1) Dissolve graphene oxide and docusate sodium sodium salt in dimethylformamide at the same time, ultrasonically pulverize at room temperature until completely dispersed, and stir evenly to obtain a certain concentration of graphene oxide / docusate sodium sodium salt dispersion liquid;

[0015] (2) Polycaprolactone is dissolved in the mixed solution of dichloromethane and docusate sodium sodium salt, and magnetically stirred at room temperature until it is evenly mixed to obtain a certain concentration of polycaprolactone / (dichloromethane and docusate Sodium sodium salt) solution;

[0016] (3) Graphene oxide solution and polycaprolactone solution are mixed in proportion, stirred and mixed, obtain polycaprolactone-graphene oxide solution;

[0017] (4) After the above-mentioned mixed liquid is ultrasonically treate...

Embodiment 1

[0028] In this example, a graphene oxide solution was prepared using docusate sodium sodium salt as a surfactant, and a polycaprolactone-graphene oxide composite porous scaffold material was prepared by electrospinning technology:

[0029] Step 1: Dissolve 0.06g of graphene oxide and 0.005g of docusate sodium salt in 10ml of dimethylformamide at the same time, ultrasonically pulverize at room temperature until completely dispersed, and stir evenly to obtain a concentration of 6mg / ml graphene oxide / docusate sodium salt dispersion liquid;

[0030] Step 2: Dissolve 1.12g of polycaprolactone in 8ml of a mixture of dichloromethane and docusate sodium sodium salt (volume ratio 1:1), stir at room temperature until uniformly mixed, and obtain a concentration of 140mg / ml of polycaprolactone solution;

[0031] Step 3: mixing the graphene oxide solution and the polycaprolactone solution at a mass ratio of 0.2%, stirring and mixing to obtain a polycaprolactone-graphene oxide solution; ...

Embodiment 2

[0034] In this example, a graphene oxide solution was prepared using docusate sodium sodium salt as a surfactant, and a polycaprolactone-graphene oxide composite porous scaffold material was prepared by electrospinning technology:

[0035] Step 1: Dissolve 0.08g of graphene oxide and 0.006g of docusate sodium sodium salt in 10ml of dimethylformamide at the same time. At room temperature, ultrasonically pulverize until completely dispersed, and stir evenly to obtain a concentration of 8mg Graphene oxide / docusate sodium sodium salt dispersion liquid of / ml;

[0036] Step 2: Dissolve 1.28g of polycaprolactone in a mixed solution of 8ml of dichloromethane and docusate sodium sodium salt (volume ratio of 1:0.9), magnetically stir overnight at room temperature, and configure the concentration to be 160% ( W / V) homogeneous polycaprolactone / (methylene chloride and docusate sodium sodium salt) solution;

[0037] Step 3: mixing the graphene oxide solution and the polycaprolactone solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com