Preparation method of ammonolysis oxidized graphene-based 3D (Three-dimensional) nanoparticle modified organic separation membrane

A nanoparticle modification, graphene-based technology, applied in the field of membrane separation, can solve the problems of easy agglomeration of inorganic nanoparticles, uneven film formation, and poor particle dispersion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

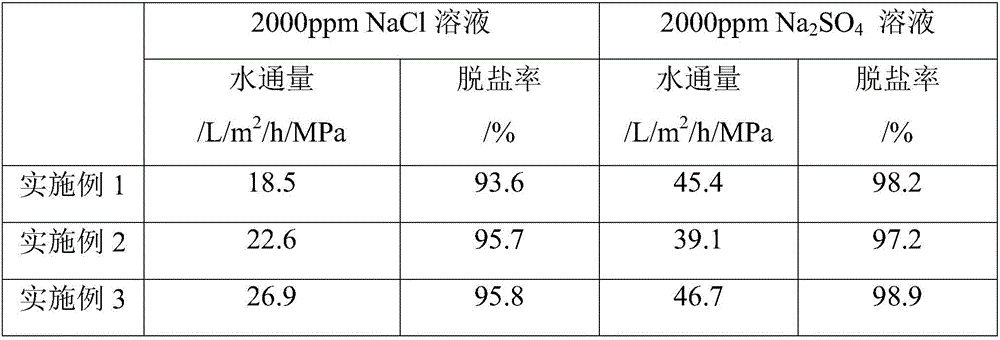

Examples

preparation example Construction

[0023] A method for preparing an ammoniated graphene oxide-based 3D nanoparticle modified organic separation membrane, comprising the steps of:

[0024] 1) Preparation of graphene oxide-based 3D nanoparticles: prepare a mixed solution of absolute ethanol and pure water with a concentration of 60-95wt%, and add 2-50 mg, 50-500 mesh graphene oxide powder into 1L of the mixed solution according to the mass ratio , adjust the pH value of the mixed solution to about 8.0-9.0 to obtain an alkaline solution, drop 0.5-5 mg of tetraethyl orthosilicate into 1L alkaline solution, ultrasonicate, store at room temperature, centrifuge, and wash repeatedly with absolute ethanol The filter cake was vacuum freeze-dried for 24 hours, and the obtained graphene oxide-based 3D nanoparticles were stored for future use;

[0025] 2) Preparation of ammoniated graphene oxide-based 3D nanoparticles: Disperse graphene oxide-based 3D nanoparticles in ethanol at a mass ratio of 1: (30-100), heat to 70-80°C,...

Embodiment 1

[0034] 1) Preparation of graphene oxide-based 3D nanoparticles: prepare a mixed solution of 60wt% absolute ethanol and pure water, add 2mg, 300 mesh graphene oxide powder to 1L mixed solution, and adjust the pH value of the mixed solution to 8.0, drop 0.5mg tetraethyl orthosilicate into 1L of alkaline solution, ultrasonicate, store at room temperature, centrifuge, and repeatedly wash the filter cake with absolute ethanol, vacuum freeze-dry for 24 hours, and store the obtained graphene oxide-based 3D nanoparticles for later use;

[0035]2) Preparation of ammoniated graphene oxide-based 3D nanoparticles: disperse 1 part of 3D graphene oxide-based nanoparticles in 30 parts of ethanol, and heat to 80°C, then add 1 wt% 3-aminopropane Trimethoxysilane (APS), the solution was refluxed for 2 hours, centrifuged, washed 4 times with a large amount of ethanol, and dried in an oven at 55°C for 12 hours to obtain amino-modified ammoniated graphene oxide-based 3D nanoparticles.

[0036] 3) ...

Embodiment 2

[0038] 1) Preparation of graphene oxide-based 3D nanoparticles: prepare a mixed solution of 70wt% absolute ethanol and pure water, add 10 mg, 500 mesh graphene oxide powder to 1L mixed solution, and adjust the pH value of the mixed solution to 8.5. Add 1mg tetraethyl orthosilicate dropwise to 1L of alkaline solution, sonicate, store at room temperature, centrifuge, and wash the filter cake repeatedly with absolute ethanol, freeze-dry in vacuum for 24 hours, and store the obtained graphene oxide-based 3D nanoparticles for later use;

[0039] 2) Preparation of ammoniated graphene oxide-based 3D nanoparticles: Disperse 1 part of 3D graphene oxide-based nanoparticles in 45 ethanol and heat to 80°C, then add 1 wt% 3-aminopropyl Trimethoxysilane (APS), the solution was refluxed for 2 hours, centrifuged, washed 3 times with a large amount of ethanol, and dried in an oven at 45°C for 12 hours to obtain amino-modified ammoniated graphene oxide-based 3D nanoparticles.

[0040] 3) Prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com