High-wear-resistance Ti (C, N)-based metal ceramic cutter material and preparation method thereof

A ceramic tool and base metal technology, applied in the field of cermets, can solve the problems of poor hardness of cermet wear-resistant materials, and achieve the effects of improving macroscopic mechanical properties, good fluidity, and improving mechanical properties and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

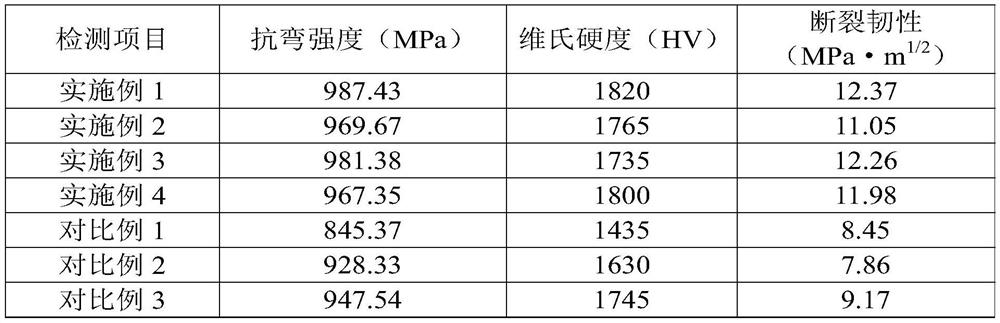

Examples

Embodiment 1

[0029] A kind of highly wear-resistant Ti(C,N)-based cermet tool material and its preparation method

[0030] The preparation method of highly wear-resistant Ti(C,N)-based cermet tool material comprises the following steps:

[0031] Step S10, put the tungsten carbide powder in the cleaning agent, raise the temperature to 72°C and perform ultrasonic treatment for 18 minutes, wash, filter, and dry, then put it in a nitric acid solution with a concentration of 58%, oscillate ultrasonically for 20 minutes, and wash until After neutralization, put it in an oven and dry at 56°C to obtain pretreated tungsten carbide powder; the formula of the above cleaning agent includes: sodium hydroxide 15g / L, sodium phosphate 9g / L, sodium carbonate 16g / L;

[0032] Step S20, prepare the plating solution: add 10g of boric acid to 100ml of water, heat and stir in a water bath at 65°C for 5 minutes to obtain a boric acid solution, dissolve 40g of cobalt chloride hexahydrate in 200ml of water, add the...

Embodiment 2

[0038] A kind of highly wear-resistant Ti(C,N)-based cermet tool material and its preparation method

[0039] The preparation method of highly wear-resistant Ti(C,N)-based cermet tool material comprises the following steps:

[0040] Step S10, put the tungsten carbide powder in the cleaning agent, raise the temperature to 65° C., perform ultrasonic treatment for 10 minutes, wash, filter, and dry, then put it in a nitric acid solution with a concentration of 55%, oscillate ultrasonically for 15 minutes, and wash until After neutralization, put it in an oven and dry at 50°C to obtain pretreated tungsten carbide powder; the formula of the above cleaning agent includes: sodium hydroxide 12g / L, sodium phosphate 6g / L, sodium carbonate 12g / L;

[0041] Step S20, prepare the plating solution: add 10g of boric acid to 100ml of water, heat and stir in a water bath at 65°C for 3 minutes to obtain a boric acid solution, dissolve 35g of cobalt chloride hexahydrate in 200ml of water, add the ...

Embodiment 3

[0047] A kind of highly wear-resistant Ti(C,N)-based cermet tool material and its preparation method

[0048] The preparation method of highly wear-resistant Ti(C,N)-based cermet tool material comprises the following steps:

[0049] Step S10, put the tungsten carbide powder in the cleaning agent, raise the temperature to 78°C for ultrasonic treatment for 25 minutes, wash, filter, and dry, then put it in a nitric acid solution with a concentration of 62%, oscillate ultrasonically for 25 minutes, and wash until After neutralization, put it in an oven and dry at 62°C to obtain pretreated tungsten carbide powder; the formula of the above cleaning agent includes: sodium hydroxide 18g / L, sodium phosphate 12g / L, sodium carbonate 20g / L;

[0050] Step S20, prepare the plating solution: add 10g of boric acid to 100ml of water, heat and stir in a water bath at 65°C for 8 minutes to obtain a boric acid solution, dissolve 45g of cobalt chloride hexahydrate in 200ml of water, add the boric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com