Antistatic polyamide composite material and preparation method thereof

A composite material and polyamide technology, applied in the field of polymer material synthesis, can solve the problems of reduced antistatic effect, poor fluidity, poor mechanical properties, etc., and achieve the effects of improving antistatic properties, reducing production costs, and reducing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

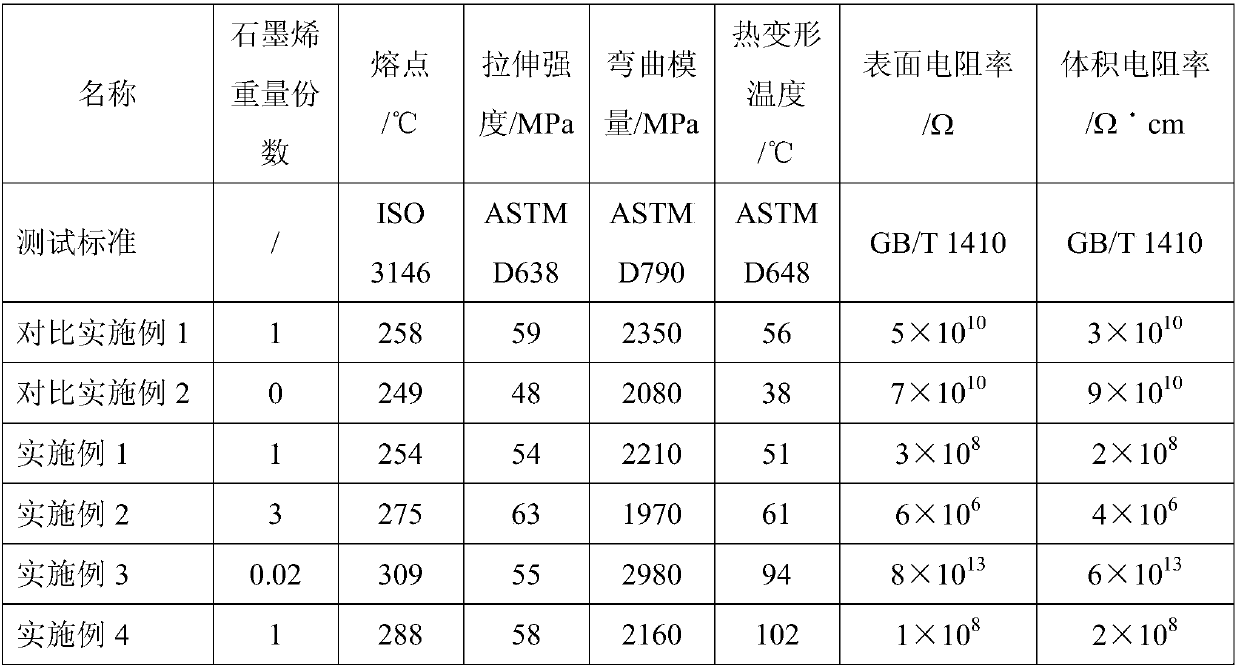

Examples

preparation example Construction

[0072]

[0073] A kind of preparation method of antistatic polyamide composite material, it comprises the following steps:

[0074] (1) 20-80 parts of aliphatic / aromatic dibasic acids, 0.2-10 parts of dibasic acids containing sulfonate groups, 20-80 parts of aliphatic dibasic amines, 2-30 parts of graphene aqueous solution, Add 0.1-0.4 parts of end-capping agent, 0.01-0.06 parts of catalyst, and 30-160 parts of deionized water into the autoclave in sequence;

[0075] (2) Vacuumize the autoclave and fill it with nitrogen to replace the air in the autoclave, then feed nitrogen until the pressure reaches 30-50kPa,

[0076] (3) Heating the autoclave, heating up to the first temperature, and reacting at constant temperature for 1-3 hours;

[0077] (4) Continue to heat up to the second temperature, and the pressure is raised to 1-3MPa thereupon, and the pressure is maintained at 1-3MPa by releasing water vapor in the autoclave;

[0078] (5) Slowly raise the temperature for 1-3 h...

Embodiment 1

[0101] The preparation method of the antistatic polyamide composite material of the present embodiment, it comprises the following steps:

[0102] (1), take by weight and be 54 parts of adipic acid, 44 parts of hexamethylenediamine, 2 parts of sodium succinic acid sulfonate, 20 parts of graphene mass fractions are 5% graphene aqueous solution, 0.25 parts of capping agent acetic acid , 0.03 parts of catalyst sodium hypophosphite, 100 parts of deionized water, and adding the above components into the autoclave;

[0103](2) Vacuumize and fill nitrogen three times to replace the air in the autoclave, and then feed nitrogen until the pressure reaches 40kPa, so that the reaction is always carried out under the protection of inert gas. After that, continue to heat up to 220°C, and the pressure will rise to 2MPa. At this time, the pressure will be kept at 2MPa by releasing the water vapor in the reactor, and the pressure will be released after slowly raising the temperature for 1.5 ho...

Embodiment 2

[0106] The preparation method of the antistatic polyamide composite material of the present embodiment, it comprises the following steps:

[0107] (1), taking by weight is 54 parts of adipic acid, 36 parts of butanediamine, 10 parts of isophthalic acid-5-sodium sulfonate, 30 parts of graphene content is 10% graphene aqueous solution, 0.4 part of sealed Terminal agent benzoic acid, 0.06 part of catalyst sodium phosphate, 40 parts of deionized water, and the above components are added in the autoclave;

[0108] (2) Vacuumize and fill nitrogen three times to replace the air in the autoclave, and then feed nitrogen until the pressure reaches 50kPa, so that the reaction is always carried out under the protection of inert gas, heat the autoclave to 80°C, and react at a constant temperature for 3 After that, continue to heat up to 180°C, and the pressure will rise to 1MPa. At this time, the pressure will be kept at 1MPa by releasing the water vapor in the reactor, and the pressure wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com