A kind of isolation medium slurry and preparation method thereof

A technology of isolating medium and slurry, applied in electrical components, insulators, circuits, etc., can solve the problems that the isolating medium slurry cannot meet the requirements, the adhesion of the isolating medium slurry is low, and the performance of the slurry is difficult to be improved, etc. The effect of improving the characteristics of easy agglomeration, reducing the hygroscopicity and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

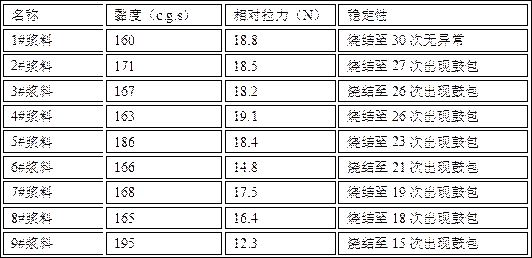

Examples

preparation example Construction

[0060] The preparation method of the isolation medium slurry according to the present invention is characterized in that it comprises:

[0061] The glass powder is soaked in sodium dodecylsulfonate solution for 20 to 24 hours, sieved and dried to obtain modified glass powder; the modified glass powder, the first carrier, the second The carrier, the cobalt oxide and the antioxidant are mixed, and after the mixing, rolling is carried out to obtain the isolation medium slurry.

[0062] The preparation method of the Ba-Si-Ca-P system glass powder is: mix barium oxide, calcium oxide, nano-silicon oxide, zinc oxide, and phosphorus pentoxide, and undergo smelting, quenching, ball milling, and drying to finally obtain a particle size D (0.5) Ba-Si-Ca-P system glass powder less than 1.0 μm.

[0063] The preparation method of the first carrier is as follows: after heating butyraldehyde oxime to 70 degrees Celsius, add attapulgite, lecithin, polyvinyl alcohol and ethyl cellulose, perfor...

Embodiment 1

[0065] Modified glass powder preparation method: according to the mass percentage of Ba-Si-Ca-P system glass powder, the composition is barium oxide 13%, calcium oxide 16%, nano-silicon oxide 35%, zinc oxide 32%, phosphorus pentoxide 4% The batching is 1 kg in total, the temperature is raised to 1400 degrees Celsius in a high-temperature resistance furnace for smelting, the holding time is 30 minutes, and the 5-liter corundum ball mill is used for refining, followed by drying for 24 hours to obtain Ba-Si with D(0.5)=0.9 μm -Ca-P system glass powder, the prepared Ba-Si-Ca-P system glass powder is soaked in 7% sodium dodecylsulfonate solution, sieved, dried, and the treatment time is 22 hours, marked as 1# glass powder.

[0066]The preparation method of the first carrier: according to the mass percentage of the first carrier, the composition is 72% of butyraldehyde oxime, 15% of ethyl cellulose, 8% of polyvinyl alcohol, 3% of lecithin, and 2% of attapulgite for batching a total ...

Embodiment 2

[0070] Preparation method of modified glass powder: according to the mass percentage of Ba-Si-Ca-P system glass powder, the composition is barium oxide 10%, calcium oxide 18%, nano-silicon oxide 35%, zinc oxide 33%, phosphorus pentoxide 4% The batching is 1 kg in total, and the temperature is raised to 1400 degrees Celsius in a high-temperature resistance furnace for smelting, the holding time is 30 minutes, and the 5-liter corundum ball mill is used for refinement, followed by drying for 24 hours to obtain Ba-Si with D(0.5)=0.8 μm -Ca-P system glass powder, soak the prepared Ba-Si-Ca-P system glass powder with 7% sodium dodecylsulfonate solution, sieve, dry, and process for 24 hours, marked as 2# glass powder.

[0071] The first carrier preparation method: according to the mass percentage of the first carrier, the composition is 80% of butyraldehyde oxime, 10% of ethyl cellulose, 5% of polyvinyl alcohol, 3% of lecithin, and 2% of attapulgite for batching a total of 25 kg; Sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com