Spacing mechanism for novel penicillin bottle feeder

A technology of vials and feeders, which is applied to packaging bottles, types of packaging items, packaging, etc., can solve problems such as product damage, fragile bottles, instability, etc., to save floor space, break bottleneck restrictions, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

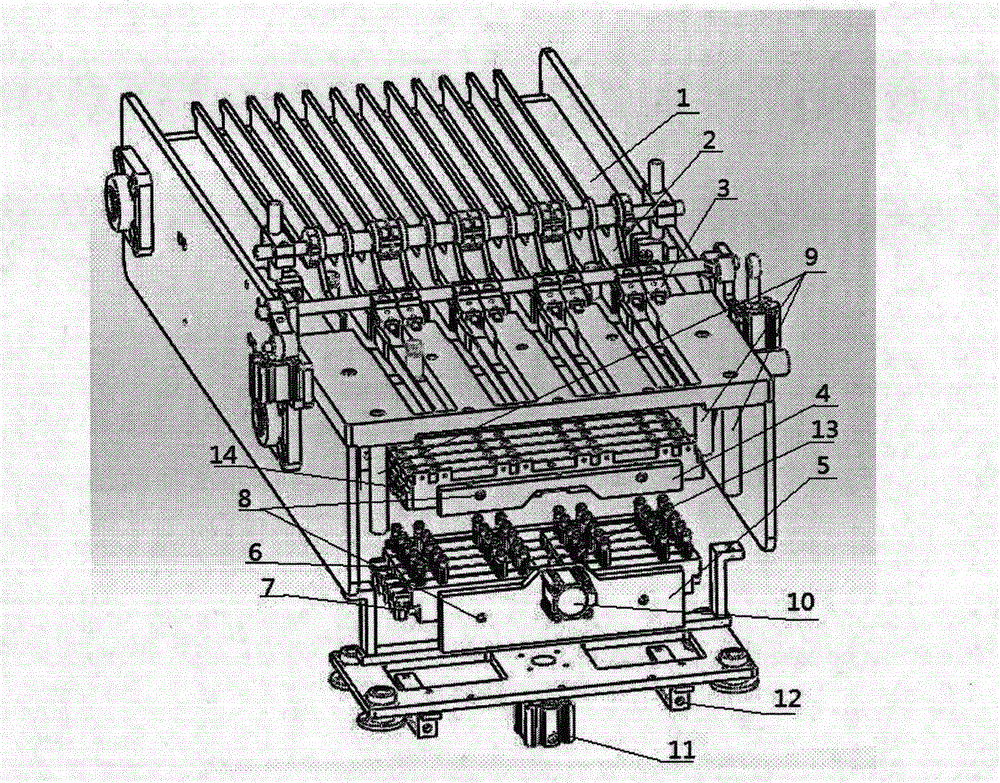

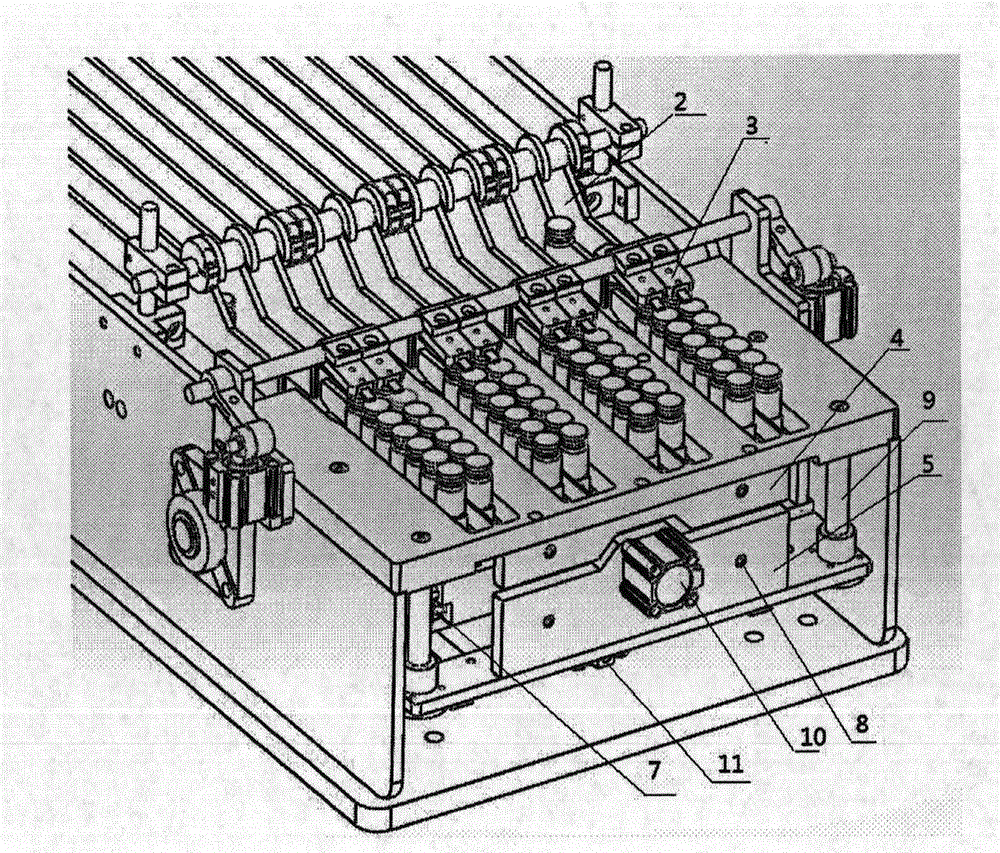

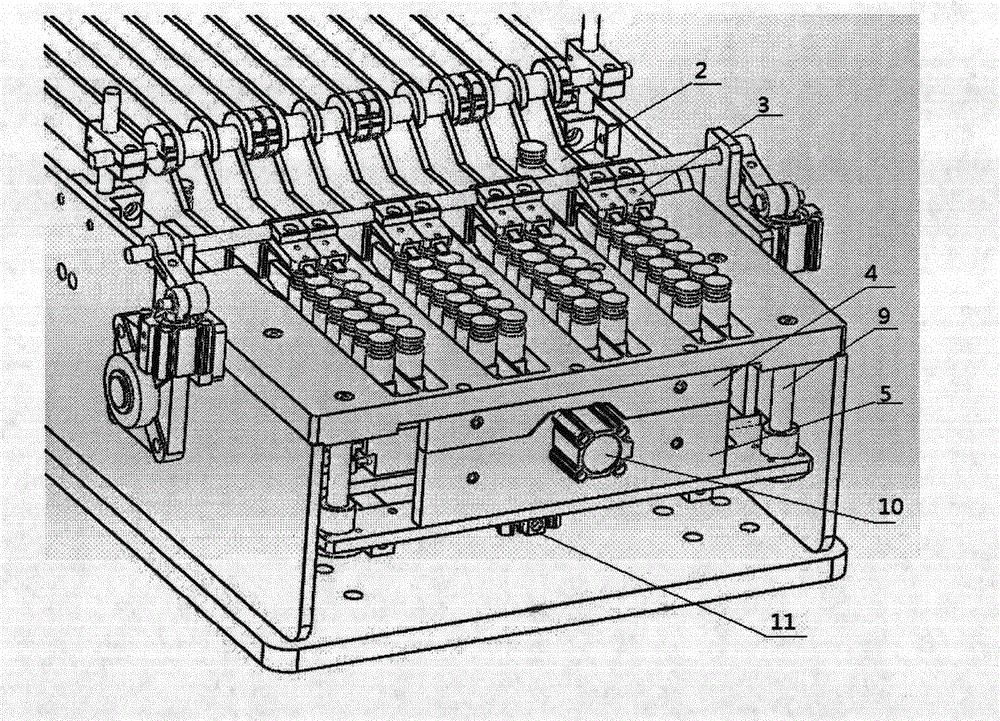

[0014] figure 2 , image 3 with Figure 4 Shown the embodiment of the novel feeder of the present invention, novel feeder multi-row horizontal spacing mechanism comprises upper horizontal spacing block (4), lower horizontal spacing block (5), suction head (6), horizontal guide Rod (8), upper and lower guide rods (9), horizontal spacing cylinder (10), upper and lower spacing cylinder (11), sliding rod (13), spacing locking buckle (7), spacing locking screw (14) . Cylinder diverter seat (12), the upper transverse distance division block (4) and the lower transverse distance division block (5) are penetrated by the transverse guide rod (8), and there are distance division locks (7) rings on both sides Interlocking, the upper horizontal spacing block (4) and the lower horizontal spacing block (5) are connected by a slide bar (13), the opening and closing have a fixed distance, and the power comes from the lower horizontal spacing block (5) The horizontal spacing cylinder (10) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com