Method for preparation of semiconductor type sulfur-doped graphene film

A technology for preparing sulfur-doped graphene and thin films, which is applied in the fields of graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of cumbersome, unsuitable for mass production, consumables steps, etc., and achieves technological route innovation, excellent optoelectronics and The effect of luminescence modulation performance, equipment and process simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

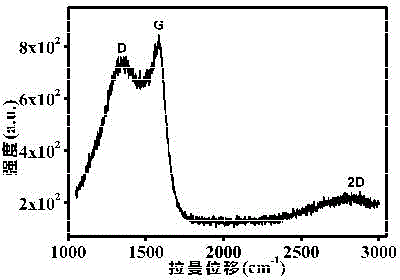

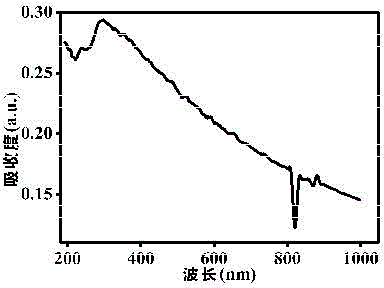

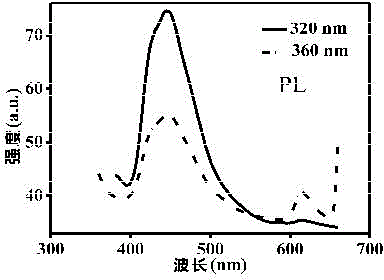

[0022] Example 1: A method for preparing a semiconductor-type sulfur-doped graphene film. The solution produced by the reaction of ethylene glycol and sulfuric acid in a certain molar ratio is spin-coated and annealed to form a sulfur-doped graphene film at one time, including liquid phase chemistry The three steps of reaction, spin coating and annealing are as follows:

[0023] 1) Liquid phase chemical reaction: Take 30 ml of ethylene glycol and 6 ml of sulfuric acid, place them in a 100 ml beaker, stir with a mechanical stirrer while heating on the heating plate, set the heating plate temperature to 200 ℃, until the mixed solution becomes uniform It is brown and does not continue to change color; filter the brown solution to remove the black carbonized precipitate in the solution, keep the uniform brown clear night, and put it in a brown sample bottle for later use;

[0024] 2) Spin coating: Use a disposable dropper to take an appropriate amount of the sulfur-doped graphene precu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com