Boride-modified glass-ceramic matrix composite high-temperature anti-oxidation coating and preparation method thereof

A high-temperature anti-oxidation and glass-ceramic technology, applied in the field of high-temperature refractory metal protection, can solve the problems of insufficient thermal erosion resistance and high preparation temperature of silicate glass-ceramic coatings, achieve improved thermal shock resistance, and simple preparation process , good heat erosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The boride-modified glass-ceramic-based composite high-temperature anti-oxidation coating of this embodiment is composed of ZrB with a mass percentage of 50%. 2 and silicate glass with a mass percentage of 50%; the silicate glass is composed of the following raw materials in mass percentage: B 2 o 3 11.5%, Al 2 o 3 8.5%, ZrO 2 6.5%, CaO 4%, KNO 3 5%, NaOH 7.5%, the balance is SiO 2 ; The composite high-temperature oxidation-resistant coating is coated on the surface of the C103 niobium alloy.

[0035] The method for preparing a boride-modified glass-ceramic matrix composite high-temperature oxidation-resistant coating in this embodiment includes the following steps:

[0036] Step 1, pickling after polishing the surface of C103 niobium alloy, then degreasing the metal surface after pickling; the acid solution used in the pickling is mixed by hydrofluoric acid solution and concentrated nitric acid solution in a volume ratio of 7:3.5 Formed, the mass concentratio...

Embodiment 2

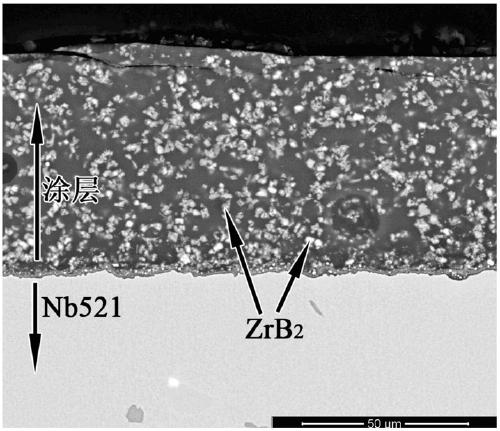

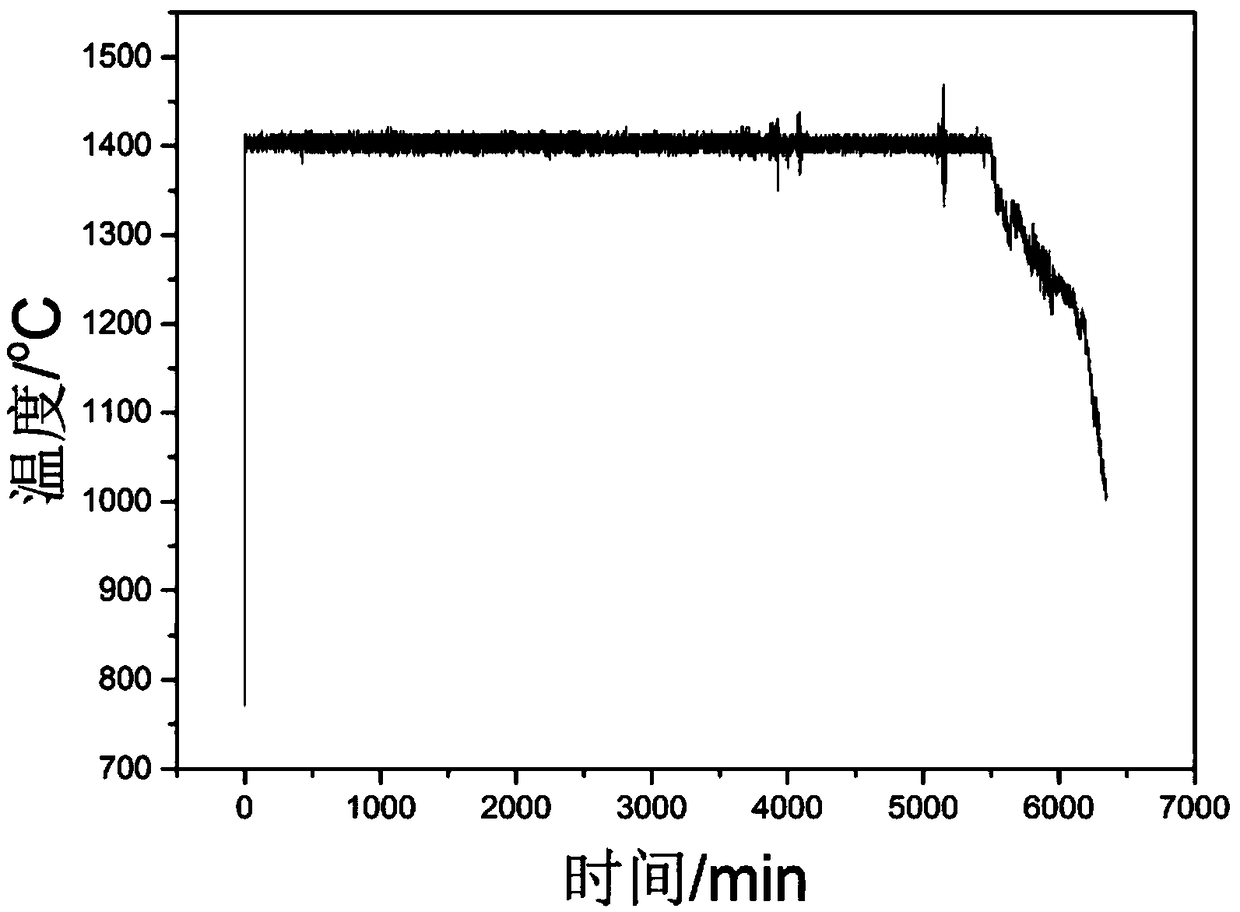

[0042] The boride-modified glass-ceramic-based composite high-temperature anti-oxidation coating of this embodiment is composed of ZrB with a mass percentage of 40%. 2 and silicate glass with a mass percentage of 60%; the silicate glass is composed of the following raw materials in mass percentage: B 2 o 3 3%, Al 2 o 3 2%, ZrO 2 3%, SrO 5%, ZnO 20%, the balance is SiO 2 ; The composite high-temperature anti-oxidation coating is coated on the surface of Nb521 niobium alloy.

[0043] The method for preparing a boride-modified glass-ceramic matrix composite high-temperature oxidation-resistant coating in this embodiment includes the following steps:

[0044] Step 1, pickling after polishing the surface of Nb521 niobium alloy, then degreasing the metal surface after pickling; the acid solution used in the pickling is mixed by hydrofluoric acid solution and concentrated nitric acid solution in a volume ratio of 6:3 Formed, the mass concentration of the hydrofluoric acid so...

Embodiment 3

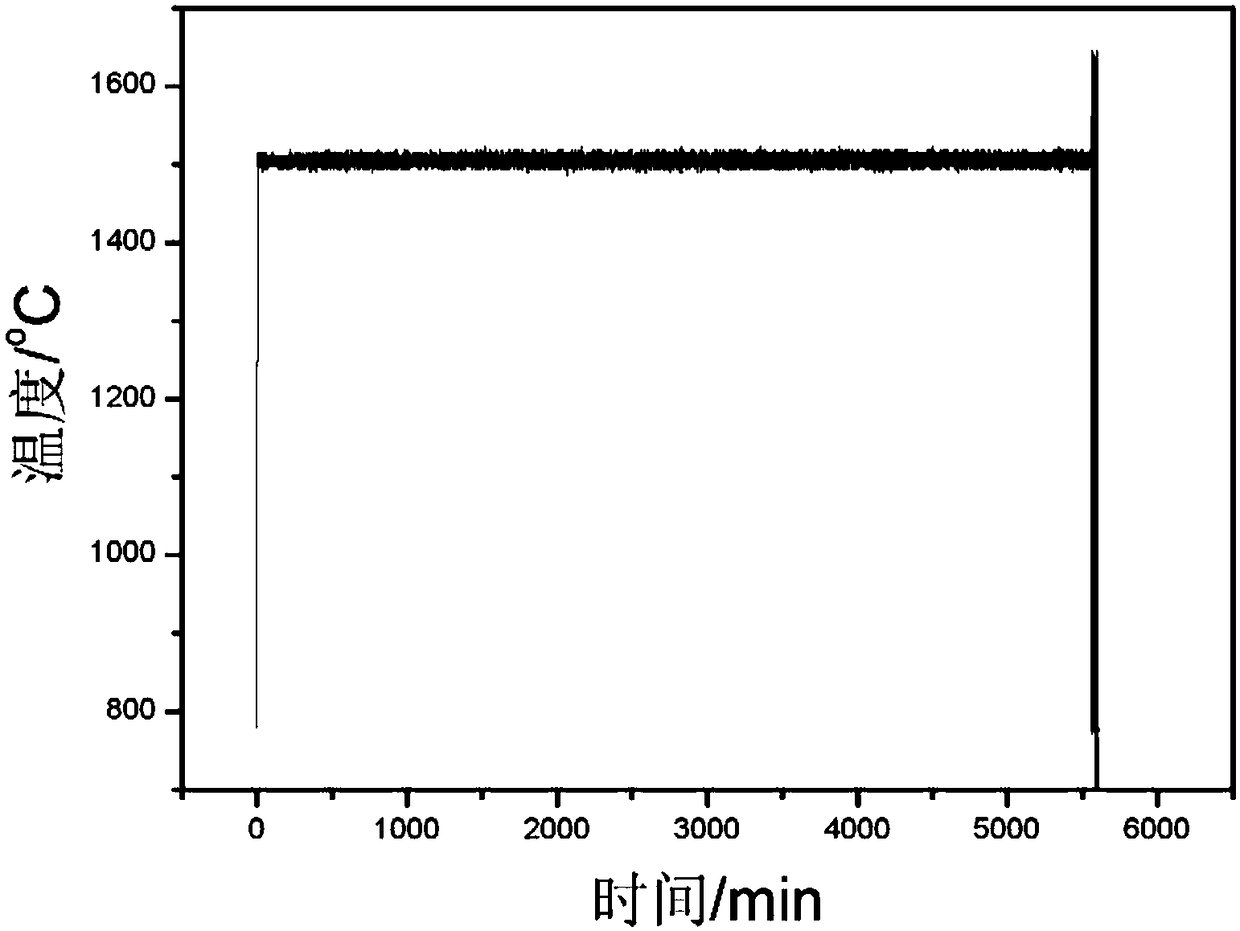

[0050] The boride-modified glass-ceramic-based composite high-temperature anti-oxidation coating of this embodiment is composed of TiB with a mass percentage content of 30%. 2 and silicate glass with a mass percentage of 60%; the silicate glass is composed of the following raw materials in mass percentage: B 2 o 3 20%, Al 2 o 3 15%, ZrO 2 10%, CaO 2 3%, KNO 3 5%, the balance is SiO 2 ; The composite high-temperature anti-oxidation coating is coated on the surface of Nb521 niobium alloy.

[0051] The method for preparing a boride-modified glass-ceramic matrix composite high-temperature oxidation-resistant coating in this embodiment includes the following steps:

[0052] Step 1, pickling after grinding the surface of Nb521 niobium alloy, and then degreasing the metal surface after pickling; the acid solution used in the pickling is mixed by hydrofluoric acid solution and concentrated nitric acid solution in a volume ratio of 6:4 Formed, the mass concentration of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com