Method for preparing inorganic porous material from magma soil by alkali activation

A technology of inorganic porous materials and magma soil, which is applied in the production of clay products, ceramic materials, ceramic products, etc., can solve the problems of poor heat insulation and sound insulation effects, large capacity, etc., achieve high-strength heat insulation and sound insulation performance, and realize building energy saving , Good heat insulation and sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

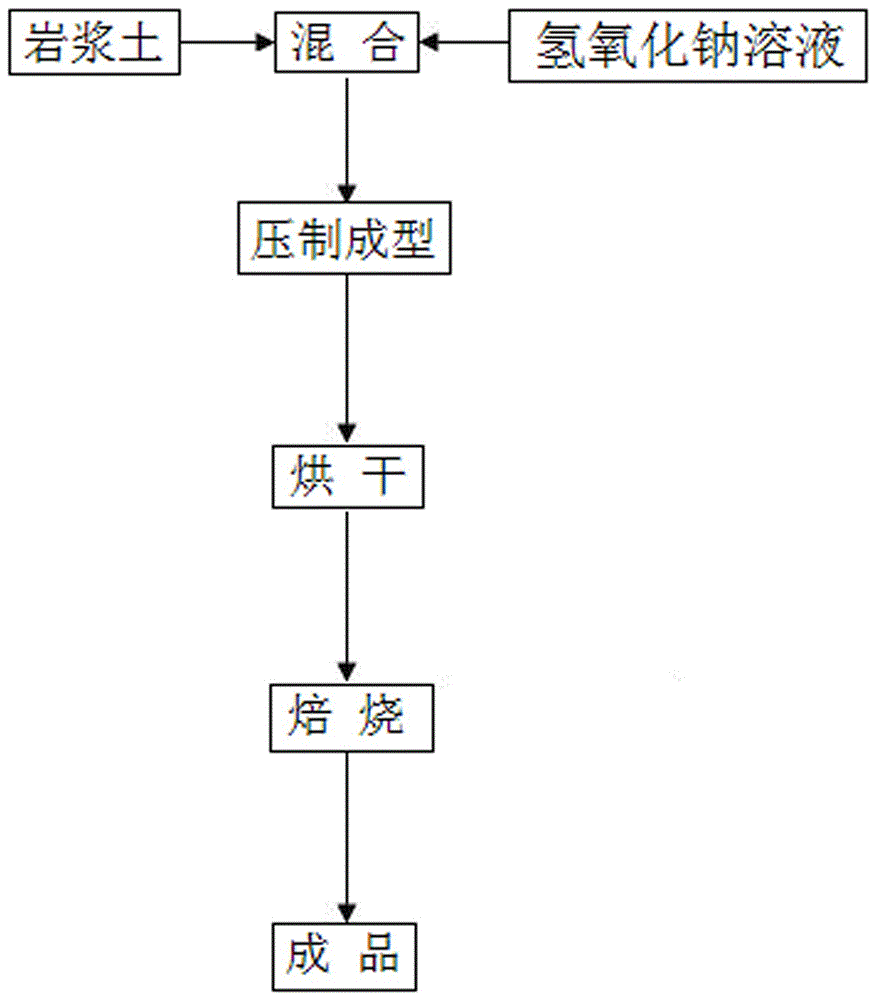

Method used

Image

Examples

Embodiment 1

[0030] The magma soil is used as the main raw material, and sodium hydroxide is used as the alkali activator. Weigh respectively: 200g of magma soil after removing impurities, and 100g of sodium hydroxide solution (4M).

[0031] The magmatic soil is crushed to pass through a 200 mesh sieve.

[0032] Put the above two raw materials into a kneader for thorough mixing.

[0033] The kneaded mixture is placed in a mold for compression molding, and the pressure is 5 MPa.

[0034] Put the molded sample belt mold in an oven and dry it at 115°C for 1 hour. After cooling, the sample is hardened and released from the mold.

[0035] The demolded samples were placed in a muffle furnace, treated at 350°C for 1 hour, and cooled down to room temperature naturally.

[0036] The bulk density of the sample prepared above is 1412 kg / m 3 , the compressive strength is 10.5 MPa, and the average pore diameter is 0.6~0.82mm.

Embodiment 2

[0038] The magma soil is used as the main raw material, and sodium hydroxide is used as the alkali activator. Weigh respectively: 200g of magma soil after removing impurities, and 100g of sodium hydroxide solution (4M).

[0039] The magmatic soil is crushed to pass through a 230 mesh sieve.

[0040] Put the above two raw materials into a kneader for thorough mixing.

[0041] The kneaded mixture is placed in a mold for compression molding, and the pressure is 5 MPa.

[0042] Put the molded sample belt mold in an oven and dry it at 105°C for 1 hour. After cooling, the sample is hardened and released from the mold.

[0043] The demolded samples were placed in a muffle furnace, treated at 500 °C for 1 hour, and cooled down to room temperature naturally.

[0044] The bulk density of the sample prepared above is 712 kg / m 3 , the compressive strength is 7.52 MPa, and the average pore diameter is 0.8~1.2mm.

Embodiment 3

[0046] The magma soil is used as the main raw material, and sodium hydroxide is used as the alkali activator. Weigh respectively: 200g of magma soil after removing impurities, 100g of sodium hydroxide solution (8M).

[0047] The magma soil is crushed to pass through a 270 mesh sieve.

[0048] Put the above two raw materials into a kneader for thorough mixing.

[0049] The kneaded mixture is placed in a mold for compression molding, and the pressure is 5 MPa.

[0050] Put the molded sample belt mold in an oven and dry it at 110°C for 1 hour. After cooling, the sample is hardened and released from the mold.

[0051] The demolded samples were placed in a muffle furnace, treated at 500 °C for 1 hour, and cooled down to room temperature naturally.

[0052] The bulk density of the sample prepared above is 612 kg / m 3 , the compressive strength is 4.7 MPa, and the average pore diameter is 3.6~4.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com