Preparation method and preparation system of cyclohexanone

A technology of cyclohexanone and cyclohexane, which is applied in the field of preparation of cyclohexanone, can solve the problems of difficulty in repeating the synthesis of TS-1 molecular sieve, difficult synthesis of catalysts, difficult and stable reaction activity, etc. The effect of new hydrogen consumption and plant space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

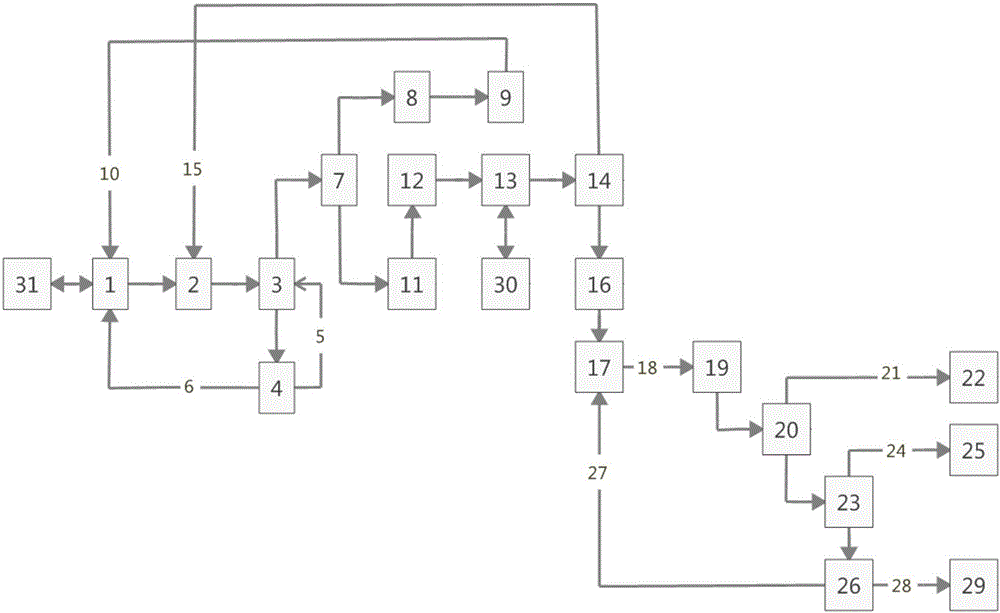

[0062] A method and system for producing cyclohexanone, which optimizes the traditional preparation process of cyclohexanone, and the specific processing method includes the following steps:

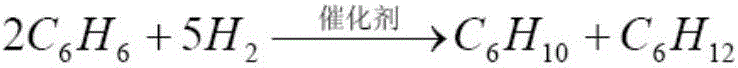

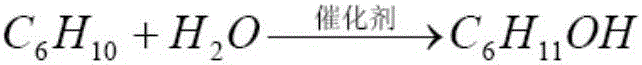

[0063] Step 1, benzene partial hydrogenation process

[0064] The raw material benzene sent from the tank group performs heat exchange with the benzene from the benzene preprocessor in the first, second and third heat exchangers of the benzene preprocessor. The preheated benzene is heated to about 150°C in the benzene pretreatment heater with medium-pressure steam and sent to the benzene pretreatment, where the benzene removes sulfur-containing impurities such as thiophene. The benzene from the benzene pretreatment is exchanged in the first, second and third heat exchangers of the benzene pretreatment, and then sent to the benzene pretreatment cooler to be cooled to 40°C with circulating water, and then sent together with the benzene recovered from the extraction and rectification proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com