Preparation method of water-soluble high-molecular cyclodextrin polymer

A technology of cyclodextrin polymer and water-soluble polymer, which is applied in the field of preparation of water-soluble polymer cyclodextrin polymer, can solve the problems such as the inability to apply drug compatibilization, and achieves high practical value, high water solubility, and inclusion. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

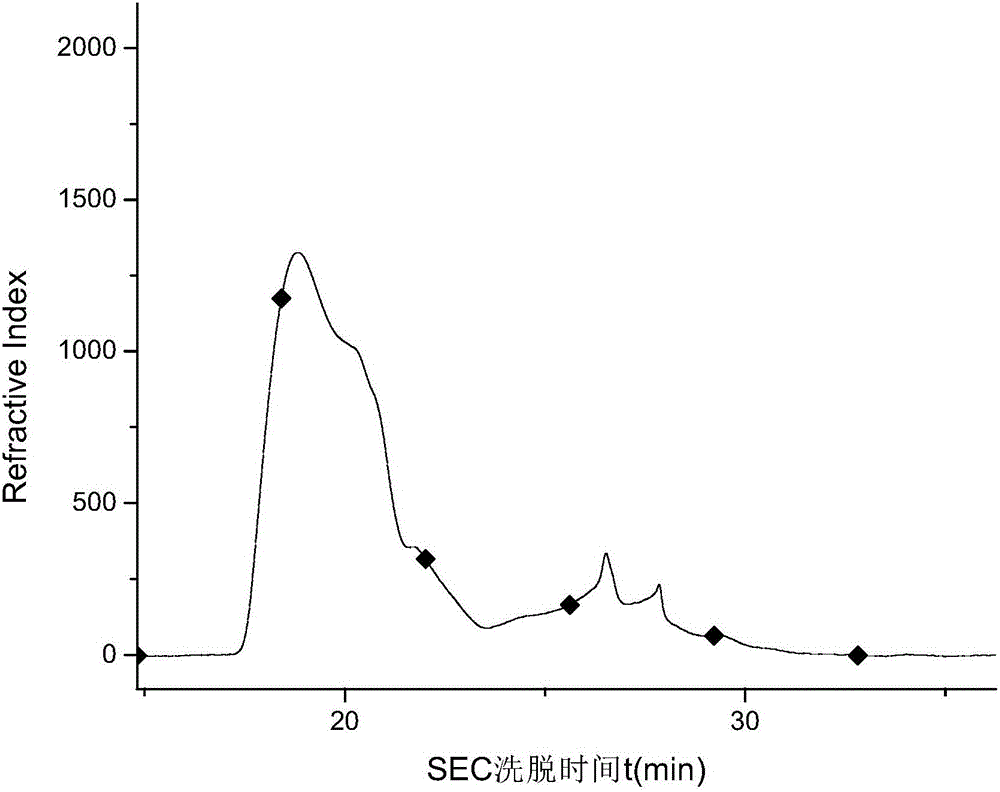

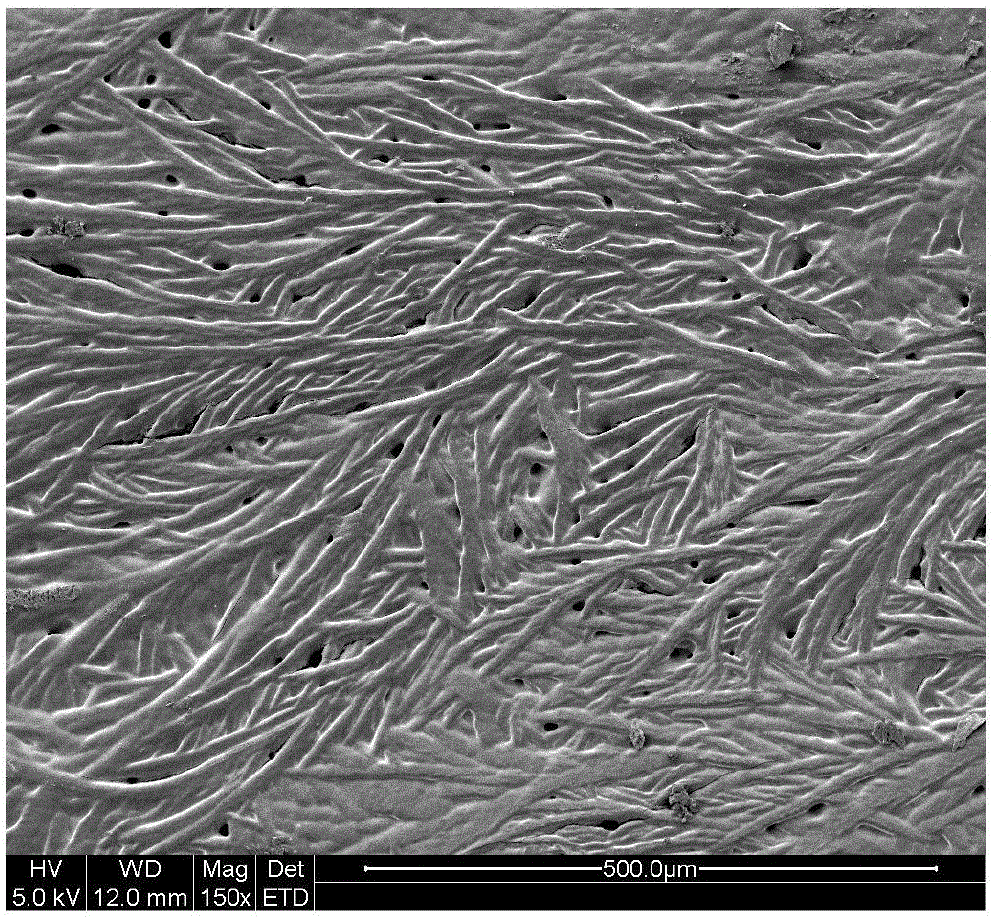

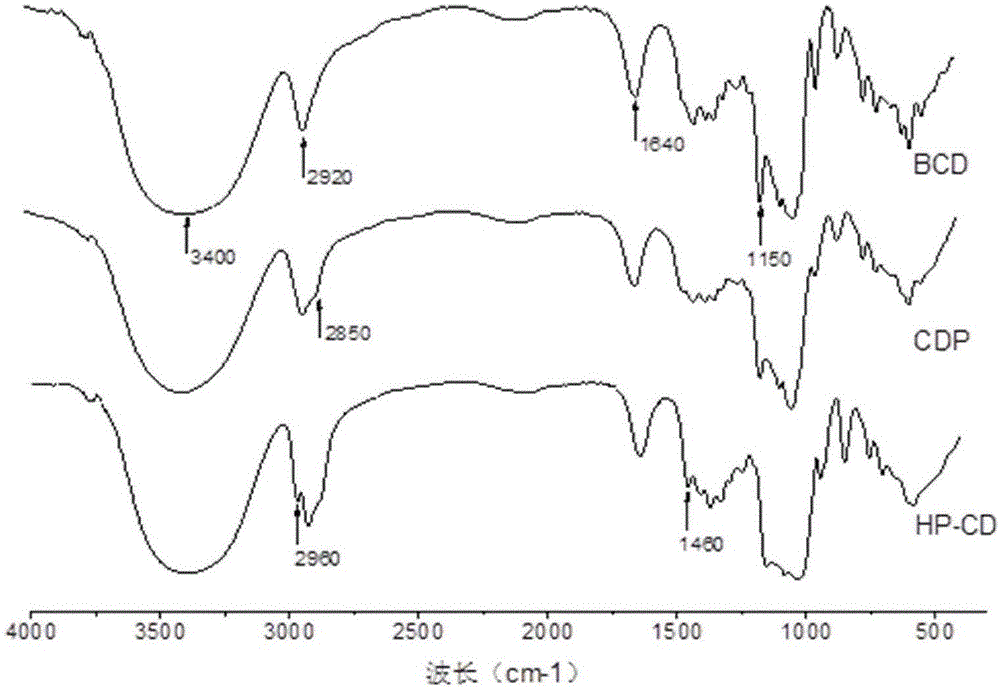

Examples

Embodiment 1

[0020] 1) Dissolve 10g of cyclodextrin into 16ml of 20wt% NaOH aqueous solution, continue to stir for 12 hours to dissolve into a transparent solution, and the hydroxyl group is fully activated, then add 2ml of absolute ethanol and stir evenly;

[0021] 2) Heating and maintaining the cyclodextrin solution obtained in step (1) at 30°C, adding epichlorohydrin whose molar weight is 5-8 times that of cyclodextrin, stirring and continuing to react for 180-360 minutes;

[0022] 3) Then pour 0.5 to 1 times the volume of acetone in the reaction system obtained in step (2) to terminate the reaction, stir at 200 rpm for 5 minutes and then let it stand, and remove the acetone in the upper layer after the system is layered; add hydrochloric acid solution drop by drop to dissolve the reaction system Adjust to neutrality; the obtained neutral product is poured into absolute ethanol whose volume is 4 times its volume, centrifuged at 2000g for 10min, and the viscous liquid at the bottom is ret...

Embodiment 2

[0025] 1) Dissolve 13g of cyclodextrin into 20ml of 25wt% NaOH aqueous solution, continue stirring for 13 hours to dissolve into a transparent solution, and the hydroxyl group is fully activated, then add 5ml of absolute ethanol and stir evenly;

[0026] 2) Heating and maintaining the cyclodextrin solution obtained in step (1) at 35°C, adding epichlorohydrin whose amount is 6 times the molar amount of cyclodextrin, stirring and continuing to react for 270 minutes;

[0027] 3) Then pour acetone of 0.7 times the volume of the reaction system obtained in step (2) to terminate the reaction, stir at 220rpm for 6min and then let stand, remove the acetone in the upper layer after the system is layered; add hydrochloric acid solution drop by drop to adjust the reaction system to Neutral; the resulting neutral product is poured into absolute ethanol 5 times its volume, centrifuged at 2500g for 15min, and the viscous liquid at the bottom is collected;

[0028] 4) Dilute the viscous liqu...

Embodiment 3

[0030] 1) Dissolve 15g of cyclodextrin into 25ml of 30wt% NaOH aqueous solution, continue to stir for 15 hours to dissolve into a transparent solution, and the hydroxyl group is fully activated, then add 8ml of absolute ethanol and stir evenly;

[0031] 2) Heating the cyclodextrin solution obtained in step (1) and maintaining it at 40°C, adding epichlorohydrin whose amount is 8 times the molar amount of cyclodextrin, stirring and continuing to react for 360 minutes;

[0032] 3) Then pour acetone of 1 times the volume of the reaction system obtained in step (2) to terminate the reaction, stir at 240rpm for 8min and then let stand, remove the acetone in the upper layer after the system is layered; add hydrochloric acid solution dropwise to adjust the reaction system to Neutral; the resulting neutral product is poured into anhydrous ethanol whose volume is 6 times its volume, centrifuged at 3000g for 20min, and the viscous liquid at the bottom is collected;

[0033] 4) Dilute the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com