Pumice phenolic resin compound foam material and preparation method thereof

A phenolic resin and composite foam technology, applied in the field of thermal insulation materials, can solve the problems of poor thermal insulation performance of inorganic thermal insulation materials, low strength of phenolic foam materials, poor flame retardant performance, etc. The effect of improving the chalking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

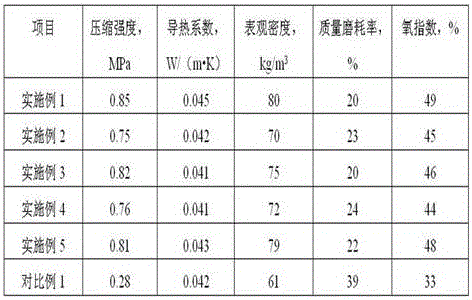

Embodiment 1

[0040] A pumice phenolic resin composite foam material, calculated in parts by weight, each part by weight corresponds to 1g, and weighs the following raw materials:

[0041] 80 parts of phenolic resin, 40 parts of pumice powder, 3 parts of surfactant, 5.5 parts of foaming agent, 4 parts of curing agent;

[0042] Wherein, the phenolic resin is prepared from phenol, paraformaldehyde and alkaline catalyst solution in a mass ratio of 100:60:1.5.

[0043] The above-mentioned basic catalyst is a sodium hydroxide solution, preferably an aqueous sodium hydroxide solution with a mass fraction of 20%. The above-mentioned phenolic resin has a solid content of 80%-85%, a viscosity of 2-3 Pa.S at 25°C, a mass fraction of free aldehyde of 1%-2%, and a pH value of 7-9. The above-mentioned surfactant is one of silicone-based surfactants or Tween-based surfactants. Tween-80 is preferred. Above-mentioned blowing agent is petroleum ether, n-pentane, n-hexane, isopentane or cyclopentane. Pet...

Embodiment 2

[0057] A pumice phenolic resin composite foam material, calculated in parts by weight, each part by weight corresponds to 1g, and weighs the following raw materials:

[0058] 120 parts of phenolic resin, 50 parts of pumice powder, 5 parts of surfactant, 8.5 parts of foaming agent, 6 parts of curing agent;

[0059] Wherein, the phenolic resin is prepared from phenol, paraformaldehyde and alkaline catalyst solution in a mass ratio of 90:50:2.5.

[0060] The above-mentioned basic catalyst is a sodium hydroxide solution, preferably an aqueous sodium hydroxide solution with a mass fraction of 20%. The above-mentioned phenolic resin has a solid content of 80%-85%, a viscosity of 2-3 Pa.S at 25°C, a mass fraction of free aldehyde of 1%-2%, and a pH value of 7-9. The above-mentioned surfactant is one of silicone-based surfactants or Tween-based surfactants. Tween-80 is preferred. Above-mentioned blowing agent is petroleum ether, n-pentane, n-hexane, isopentane or cyclopentane. Pet...

Embodiment 3

[0074] A pumice phenolic resin composite foam material, calculated in parts by weight, each part by weight corresponds to 1g, and weighs the following raw materials:

[0075] 100 parts of phenolic resin, 45 parts of pumice powder, 4 parts of surfactant, 7 parts of foaming agent, 5 parts of curing agent;

[0076] Wherein, the phenolic resin is prepared from phenol, paraformaldehyde and alkaline catalyst solution in a mass ratio of 95:55:2.

[0077] The above-mentioned basic catalyst is a sodium hydroxide solution, preferably an aqueous sodium hydroxide solution with a mass fraction of 20%. The above-mentioned phenolic resin has a solid content of 80%-85%, a viscosity of 2-3 Pa.S at 25°C, a mass fraction of free aldehyde of 1%-2%, and a pH value of 7-9. The above-mentioned surfactant is one of silicone-based surfactants or Tween-based surfactants. Tween-80 is preferred. Above-mentioned blowing agent is petroleum ether, n-pentane, n-hexane, isopentane or cyclopentane. Petrole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com