House leakage repair high-viscosity cold-flow adhesive tape and preparation method thereof

A cold flow, leak repair technology, applied in the direction of non-polymer adhesive additives, adhesives, film/sheet adhesives, etc., can solve the problems of difficult gap sealing, poor sealing effect, roof cracks, etc. The effect of low surface treatment requirements, easy operation and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

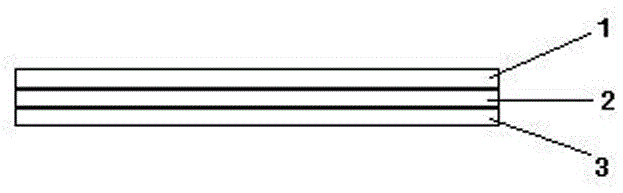

[0036] Embodiment 1: refer to attached figure 1 .

[0037] A house leak-trapping high-viscosity cold-flow adhesive tape, which is composed of a protective film 1, a house-trapping high-viscosity cold-flow adhesive layer 2 and an isolation film 3 arranged in sequence, and the protective film 1 is pasted on one side of the house leak-trapping high-viscosity cold-flow adhesive layer 2, The isolation film 3 is pasted on the other side of the high-viscosity cold-flow adhesive layer 2 for leak trapping in the house;

[0038] The protective film 1 is a polyester film (i.e. polyester film, referred to as PET film or PET), and the isolation film 3 is a polyethylene film (i.e. polyethylene film, referred to as PE or PE film);

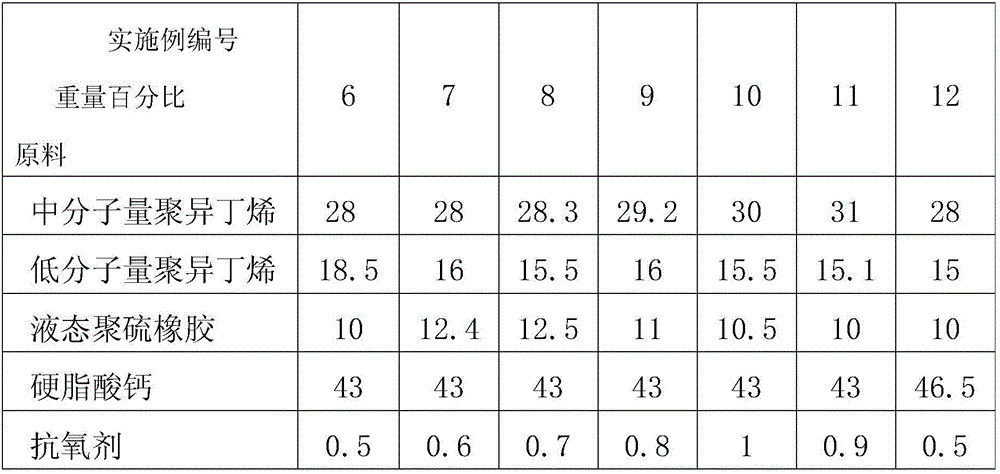

[0039] The high-viscosity cold-flow adhesive layer 2 for leak-trapping houses is composed of the following raw material components and weight percentage ratios: 28% of medium molecular weight polyisobutylene, 15% of low molecular weight polyisobutylene, 10% of l...

Embodiment 2

[0041] A house leak-trapping high-viscosity cold-flow adhesive tape, which is composed of a protective film 1, a house-trapping high-viscosity cold-flow adhesive layer 2 and an isolation film 3 arranged in sequence, and the protective film 1 is pasted on one side of the house leak-trapping high-viscosity cold-flow adhesive layer 2, The isolation film 3 is pasted on the other side of the high-viscosity cold-flow adhesive layer 2 for leak trapping in the house;

[0042] The protective film 1 is a polyester film (i.e. polyester film, referred to as PET film or PET), and the isolation film 3 is a polyethylene film (i.e. polyethylene film, referred to as PE or PE film);

[0043] The house leak-trapping high-viscosity cold-flow adhesive layer 2 is composed of the following raw material components and weight percentage ratio: medium molecular weight polyisobutylene 29%, low molecular weight polyisobutylene 15.5%, liquid polysulfide rubber (JLP-121) 10.5%, hard Calcium fatty acid 44.1...

Embodiment 3

[0045] A house leak-trapping high-viscosity cold-flow adhesive tape, which is composed of a protective film 1, a house-trapping high-viscosity cold-flow adhesive layer 2 and an isolation film 3 arranged in sequence, and the protective film 1 is pasted on one side of the house leak-trapping high-viscosity cold-flow adhesive layer 2, The isolation film 3 is pasted on the other side of the high-viscosity cold-flow adhesive layer 2 for leak trapping in the house;

[0046] The protective film 1 is a polyester film (i.e. polyester film, referred to as PET film or PET), and the isolation film 3 is a polyethylene film (i.e. polyethylene film, referred to as PE or PE film);

[0047] The house leak-trapping high-viscosity cold-flow adhesive layer 2 is composed of the following raw material components and weight percentage ratio: 28% of medium molecular weight polyisobutylene, 15% of low molecular weight polyisobutylene, 13.5% of liquid polysulfide rubber, and 43% of calcium stearate , a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com