Antibacterial self-repairing microcapsule as well as preparation method and application thereof in coating

A self-healing microcapsule and self-healing technology, which is applied in the direction of microcapsule preparation, microsphere preparation, antifouling/underwater coating, etc., can solve the problems of poor product storage, poor compatibility, and microcapsule agglomeration, and achieve improved storage High stability, reduced agglomeration, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

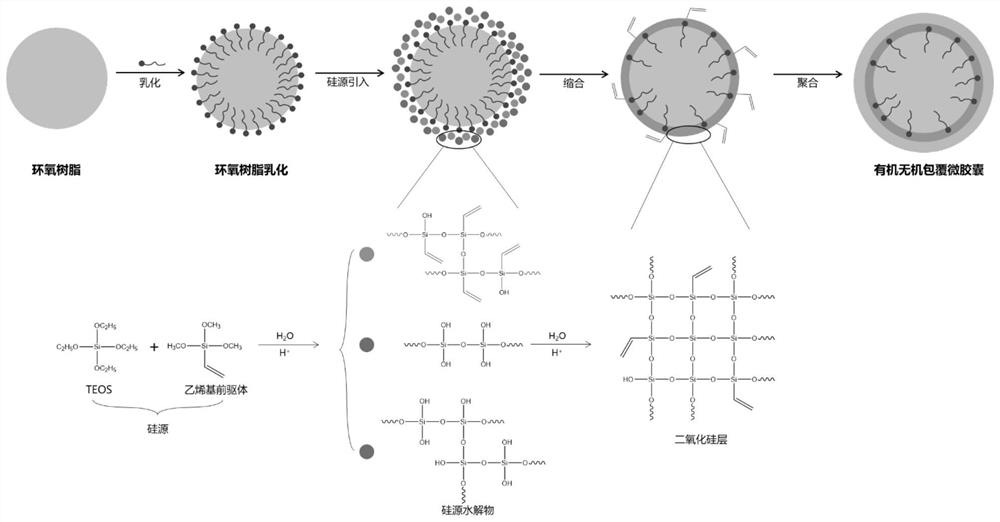

[0036] The present invention also provides the preparation method of above-mentioned antibacterial self-healing microcapsules, which comprises the following steps:

[0037] S1 adding the self-healing substance to the emulsifier to obtain a mixture;

[0038] S2 adding the silicon source material to the obtained mixture after being hydrolyzed under acidic conditions to form inorganic microcapsules with an inorganic shell-coated self-healing material;

[0039] S3 Emulsion polymerizing the obtained inorganic microcapsules with acrylic monomers to obtain the antibacterial self-repairing microcapsules.

[0040] Such as figure 1 As shown, the present invention pre-emulsifies the self-healing substance through an emulsifier, and the emulsifier coats the self-healing substance; on this basis, the silicon source material is hydrolyzed to form a hydrolyzate containing vinyl active groups, and the encapsulating The emulsifier covered with the self-healing substance undergoes interfacial...

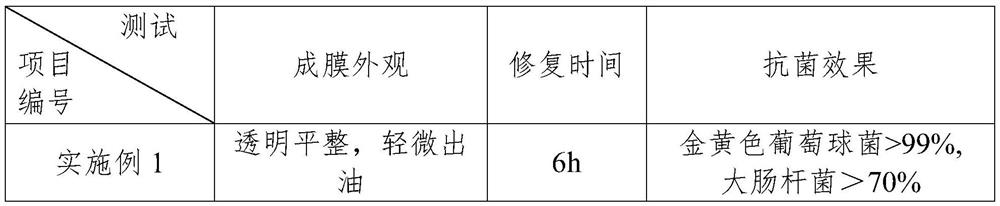

Embodiment 1

[0048] Preparation of antibacterial self-healing microcapsules:

[0049] Emulsion mixing of S1 self-healing substances

[0050]Under 1500rpm mechanical dispersion, in 100g water, add 4g PF80S (non-ionic emulsifier) to form homogeneous solution; Continue under stirring, and rotating speed is 3000rpm, adds the mixture 100g of epoxy resin E51 and cationic photoinitiator WPI113 (wherein initiator and Resin ratio is 1:20), dispersed at high speed for half an hour to form a uniform emulsified mixture.

[0051] S2 silicon source prehydrolyzate

[0052] Take 20g of ethyl orthosilicate and 10g of vinyltrimethoxysilane and add it to 70g of water under stirring at 250rpm, slowly add dilute hydrochloric acid (mass concentration: 10%) to adjust the pH of the system to 2.0; continue to stir at 40°C for 30min to form a transparent The silicon source hydrolyzate.

[0053] S3 forms inorganic microcapsules

[0054] S31 Slowly drop the silicon source pre-hydrolyzed solution into the emulsi...

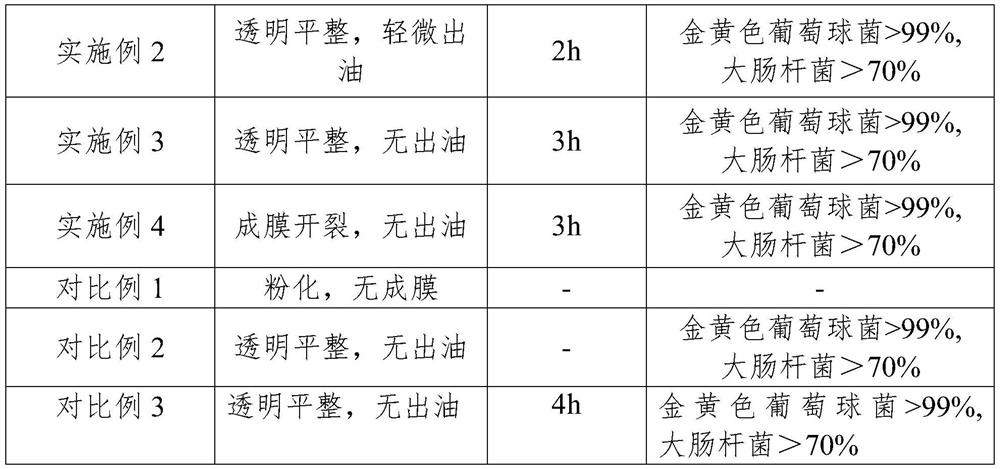

Embodiment 2

[0062] The preparation method of antibacterial self-healing microcapsules, the steps and parameters are the same as in Example 1, the difference is that the epoxy resin in step S1 is replaced by E44, and the photoinitiator is WPI113, wherein the weight ratio of the initiator to the resin is 1:5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com