Wide-temperature self-healing electrolyte, preparation method thereof and lithium battery

A technology of electrolyte and lithium battery, which is applied in the field of wide-temperature self-healing electrolyte and its preparation, and can solve problems such as service capability decline, device short circuit, and capacity reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

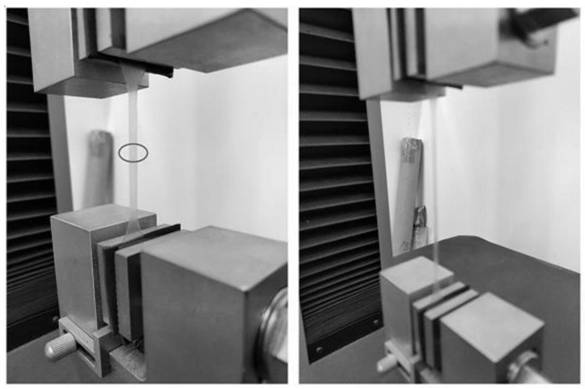

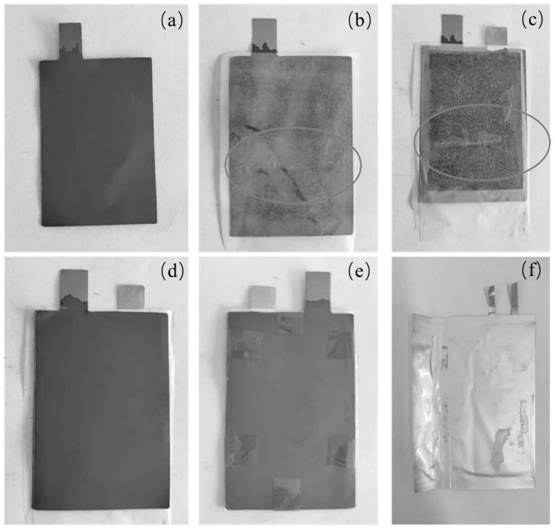

Method used

Image

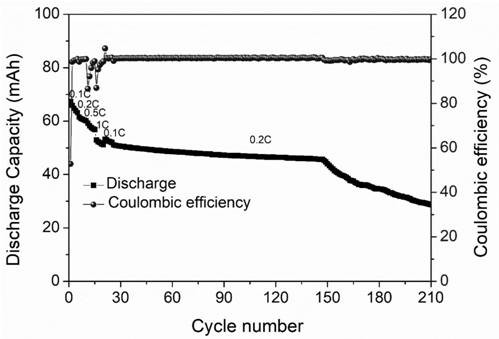

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing the wide temperature self-healing electrolyte described in the above technical solution, comprising the following steps:

[0041] S1. N-ethylethanolamine and carbon disulfide are reacted, and the product obtained is recorded as TDS;

[0042] In step S1, the reaction solution is iodine-containing chloroform, and the reaction condition is ice bath. The molar ratio of N-ethylethanolamine and carbon disulfide is 1:(0.5-1).

[0043] S2. reacting diisocyanate with hydroxyl-terminated polyether polyol to obtain isocyanate-terminated polyether polyol;

[0044] In step S2, the diisocyanate is toluene diisocyanate (TDI), isophorone diisocyanate (IPDI), diphenylmethane diisocyanate (MDI), dicyclohexylmethane diisocyanate (HMDI), hexamethylene One or more in radical diisocyanate (HDI), lysine diisocyanate, preferably toluene diisocyanate; Described polyether polyol is one or more in polyethylene glycol, polypropylene glycol...

Embodiment 1

[0051] A wide temperature self-healing electrolyte, the preparation method comprising:

[0052] S1. Add 17.8g of N-ethylethanolamine and 100ml of chloroform into the flask and mix and stir in an ice bath, then add 6ml of carbon disulfide and 12.7g of iodine to react for 3 hours, then remove impurities, and record the product as TDS.

[0053] S2. Reaction of 2,4-toluene diisocyanate and hydroxyl-terminated polypropylene glycol in chloroform at 80°C to obtain 2,4-toluene diisocyanate-terminated polypropylene glycol (molecular weight is about 2300Da)

[0054] S3. Dissolve 2 mmol of glycerol in 50 mL of chloroform CHCl 3 and pour it into a 100ml three-necked flask, then add 0.1mmol of dibutyltin dilaurate (DBTDL) into the flask, then add 6mmol of 2,4-toluene diisocyanate-terminated polypropylene glycol and 1mmol of TDS, and react at 60°C for 5h ; Pour into a polytetrafluoroethylene mold to volatilize to form a film, and obtain a wide temperature self-healing electrolyte membrane....

Embodiment 2-3 and comparative example 1

[0059] A wide temperature self-healing electrolyte, compared with Example 1, the difference is that the molar ratio of glycerol, TDS and 2,4-toluene diisocyanate-terminated polypropylene glycol is shown in Table 1, and the others are roughly the same as Example 1, I won't repeat them here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com