Novel acrylic ester glue and preparation method thereof

A technology of acrylate and isooctyl acrylate, applied in the field of new acrylate glue and its preparation, can solve the problems of long reaction time, low surface energy material bonding, low organic gas volatilization, etc. Simple, Productive Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

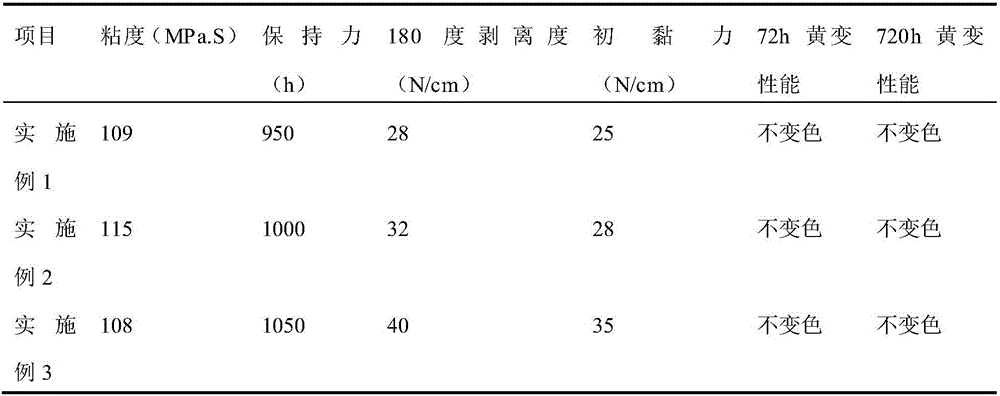

Examples

Embodiment 1

[0036] A new type of acrylate glue, comprising the following components by weight: 3750g of acrylate monomer, 250g of hydroxyethyl ester, 5g of glyceride, 25g of acrylic acid, 5500g of organic solvent, 5g of initiator, Al peroxide 13 N 2.5g;

[0037] Preferably, the acrylate monomer includes the following components: isooctyl acrylate, isobutyl acrylate, isomethyl acrylate; the organic solvent includes the following components: ethyl acetate, toluene, methanol; the The initiator is benzoyl peroxide;

[0038] Preferably, the weight of each component of the new type of acrylate glue is 3000g of isooctyl acrylate, 500g of isobutyl acrylate, 250g of isomethyl acrylate, 250g of hydroxyethyl ester, 5g of glyceride, 25g of acrylic acid, acetic acid Ethyl ester 4250g, toluene 875g, methanol 375g, benzoyl peroxide 5g, Al peroxide 13 N 2.5g;

[0039] The preparation method of a kind of novel acrylate pressure-sensitive glue of the present invention comprises the following processing ...

Embodiment 2

[0048] A new type of acrylate glue, comprising the following components in parts by weight: 5000g of acrylate monomer, 375g of hydroxyethyl ester, 20g of glyceride, 50g of acrylic acid, 7125g of organic solvent, 10g of initiator, Al peroxide 13 N 10g;

[0049] Preferably, the acrylate monomer includes the following components: isooctyl acrylate, isobutyl acrylate, isomethyl acrylate; the organic solvent includes the following components: ethyl acetate, toluene, methanol; the The initiator is benzoyl peroxide;

[0050] Preferably, for the new type of acrylate glue, the parts by weight of each component are 3750g of isooctyl acrylate, 750g of isobutyl acrylate, 500g of isomethyl acrylate, 375g of hydroxyethyl ester, 20g of glyceride, and 50g of acrylic acid , ethyl acetate 5000g, toluene 1375g, methanol 750g, benzoyl peroxide 10g, Al peroxide 13 N 10g;

[0051] The preparation method of a kind of novel acrylate pressure-sensitive glue of the present invention comprises the fo...

Embodiment 3

[0061] A new type of acrylate glue, including the following components by weight: 4375g of acrylate monomer, 325g of hydroxyethyl ester, 12.5g of glyceride, 37.5g of acrylic acid, 6312.5g of organic solvent, 7.5g of initiator, Al peroxide 13 N 6.25g;

[0062] Preferably, the acrylate monomer includes the following components: isooctyl acrylate, isobutyl acrylate, isomethyl acrylate; the organic solvent includes the following components: ethyl acetate, toluene, methanol; the The initiator is benzoyl peroxide;

[0063] Preferably, the weight of each component of the new type of acrylate glue is 3375g of isooctyl acrylate, 625g of isobutyl acrylate, 375g of isomethyl acrylate, 325g of hydroxyethyl ester, 12.5g of glyceride, and 37.5g of acrylic acid , ethyl acetate 4625g, toluene 1125g, methanol 562.5g, benzoyl peroxide 7.5g, Al peroxide 13 N 6.25g;

[0064] The preparation method of a kind of novel acrylate pressure-sensitive glue of the present invention comprises the follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com