Acrylate OCA optical adhesive film, and preparation method and application thereof

An acrylate and acrylate-based technology, which is applied in the field of acrylate OCA optical adhesive film and its preparation, can solve the problems of inability to precisely control and design molecular chains, loss of practicability of products, loss of elasticity of products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

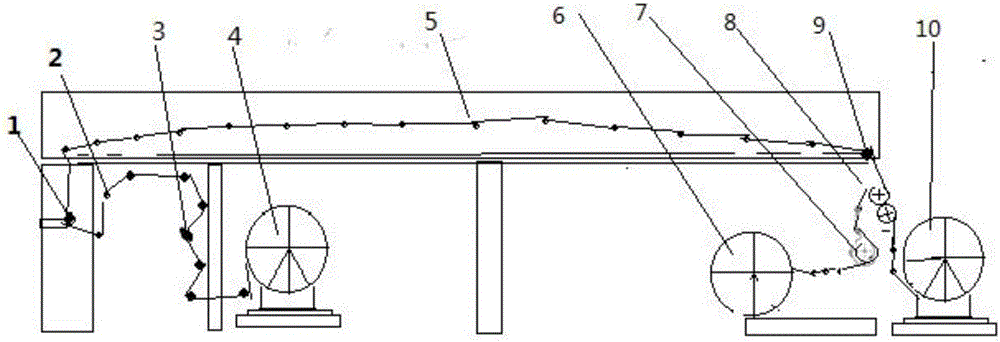

Image

Examples

Embodiment 1

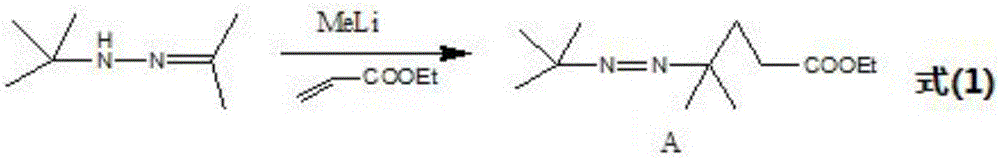

[0062] Example 1 Preparation of bifunctional initiator 4-methyl-4-tert-butylazo-peroxyvaleric acid tert-butyl ester

[0063] (1) Dissolve 12.8g of tert-butylpropionylhydrazone in 400mL of tetrahydrofuran, add 80mL of n-hexane solution with a concentration of 1.4mol / L methyllithium at -20°C to obtain reaction solution A, and react at this temperature 30min; the reaction solution was cooled to -60°C, and a solution of 13g of ethyl acrylate dissolved in 100mL of tetrahydrofuran was added to the reaction solution A to obtain a reaction solution B, and the reaction was continued for 2 hours at this temperature, and the color of the reaction solution changed from orange to When the reaction is bright yellow, the reaction is terminated; then 200 mL of n-hexane solution with 10 mL of acrylic acid is added to the reaction solution B to obtain the reaction solution C, and the reaction temperature is raised to room temperature; 300 mL of water is added to the reaction solution C, and the ...

Embodiment 2

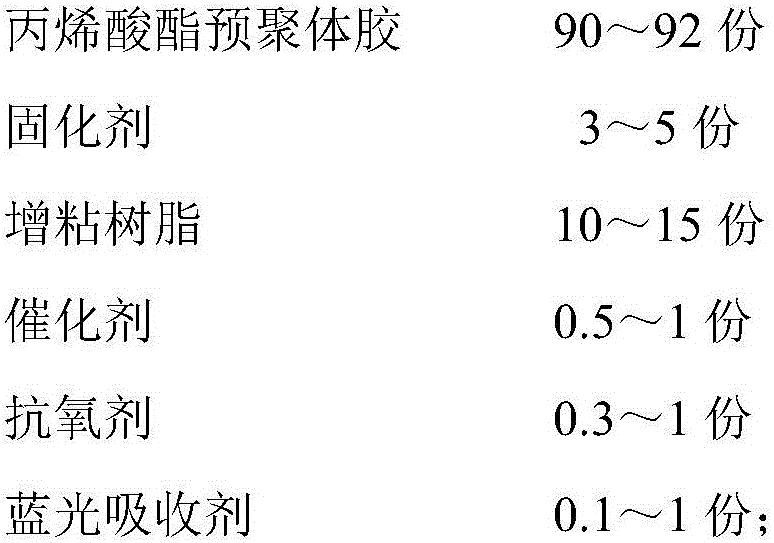

[0066] The preparation of embodiment 2 acrylate prepolymer glue

[0067] Add 200g of ethyl acetate as a reaction diluent to a 500mL reaction bottle, then add 50g of ethyl acrylate monomer, and simultaneously add 1g of hydroxyethyl acrylate and 0.1g of azoperoxybifunctional initiator 4-methyl-4-tert Butylazo-peroxyvalerate tert-butyl, feed nitrogen and start stirring, the speed is set to 80r / min, turn on the 100W LED ultraviolet lamp at room temperature, and then slowly add 0.1g of 20mL of ethyl acetate solution of bifunctional initiator 4-methyl-4-tert-butylazo-peroxyvaleric acid tert-butyl ester initiates the polymerization reaction, after 30 minutes of dropwise addition, it reacts for 1.5 hours, and its viscosity reaches about 2000cps after testing , raise the temperature to 75°C, and start to drop 100mL of ethyl acetate solution containing 85g of isooctyl methacrylate and 1g of triethylamine at the same time, and then react for about 3h after 1h of dropping, when the viscos...

Embodiment 3

[0068] The preparation of embodiment 3 acrylate prepolymer glue

[0069] In a 500mL reaction flask, add 200g of ethyl acetate as a reaction diluent, then add 60g of butyl acrylate monomer, and simultaneously add 1.2g of hydroxyethyl acrylate and 0.15g of azoperoxybifunctional initiator 4-methyl-4- tert-butyl azo peroxyvalerate tert-butyl, feed nitrogen and start stirring, the speed is set to 90r / min, turn on the 100W LED ultraviolet lamp at room temperature, then slowly add 0.15 25mL of ethyl acetate solution of g bifunctional initiator 4-methyl-4-tert-butylazoperoxyvaleric acid tert-butyl ester initiates the polymerization reaction, and after 40min dropwise addition, it reacts for about 2h, and its viscosity reaches the When the viscosity reaches about 1500cps, raise the temperature to 80°C, and start to drop 150mL of ethyl acetate solution containing 100g of isooctyl methacrylate and 1.5g of triethylenediamine at the same time, and then react for 2.5h after 1h of dropping W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com