Novel cloth washing water and preparation method thereof

A new type of deionized water technology, applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problems of reduced decontamination effect and reduced utilization rate, and achieve better effect and improved solubility. , Reasonable effect of formula combination design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

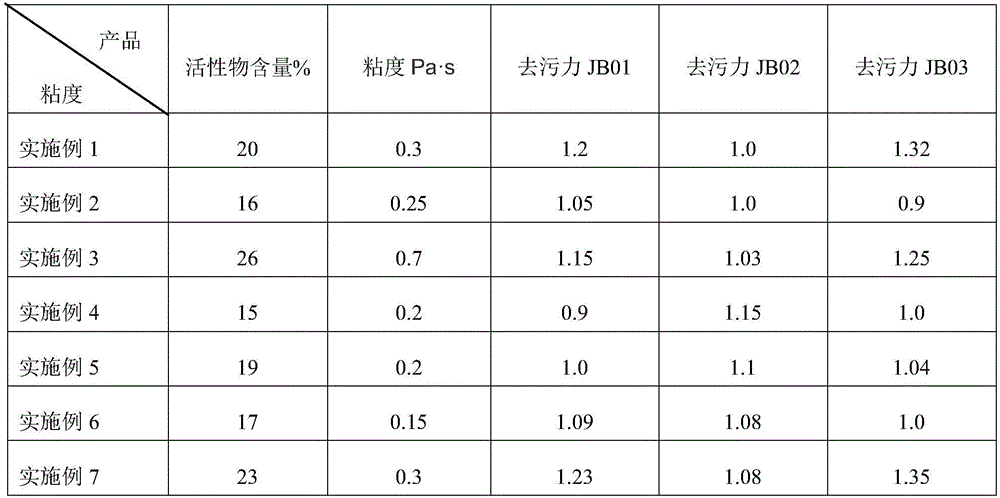

Examples

Embodiment 1

[0027] Step 1. Add 60 parts of deionized water into the mixing tank, heat up to 40-45°C, add 3 parts of sodium laureth sulfate, 4 parts of C12-20 alkyl glucoside, and 3 parts of branched AEO7 Keep stirring for 15 minutes;

[0028] Step 2. Add 0.5 parts of sodium xylene sulfonate and 0.2 parts of PPG-24-glyceryl polyether-24 in turn to the mixing tank, and stir for 3-5 minutes;

[0029] Step 3, add 10 parts of C14-17 secondary alkyl sodium sulfonate and stir for 5-10min;

[0030] Step 4, add 0.05 part of tetrasodium edetate, 0.1 part of 1.5% effective amount of Cathone, 0.2 part of cocoeth-7, 0.1 part of PEG-40 hydrogenated castor oil and 0.5 part of essence mixture successively, supplement Add deionized water until the sum of all components is 100 parts, and stir for 30 minutes to obtain the laundry water of the present invention.

Embodiment 2

[0032] Step 1. Add 60 parts of deionized water into the mixing tank, heat up to 40-45°C, add 6 parts of sodium laureth sulfate, 2 parts of C12-20 alkyl glucoside, and 3 parts of AEO3 and keep stirring for 20 minutes ;

[0033] Step 2. Add 0.5 parts of polyacrylate and 0.3 parts of PPG-24-glyceryl polyether-24 in turn to the mixing tank, and stir for 3-5 minutes;

[0034] Step 3, add 5 parts of C14-17 secondary alkyl sodium sulfonate and stir for 5-10min;

[0035] Step 4, adding 0.05 part of disodium edetate, 0.08 part of 1.5% effective amount of Cathone, 0.2 part of PPG-1-PEG-9 lauryl glycol ether, 0.2 part of PEG-40 hydrogenated castor oil and 0.5 part of Add deionized water to the essence mixture until the sum of all components is 100 parts, and stir for 30 minutes to obtain the laundry water of the present invention.

Embodiment 3

[0037] Step 1. Add 60 parts of deionized water into the mixing tank, heat up to 40-45°C, add 6 parts of sodium laureth sulfate, 5 parts of C12-20 alkyl glucoside, and 5 parts of branched AEO7 to keep warm Stir for 20min;

[0038] Step 2. Add 0.2 parts of sodium xylene sulfonate, 0.3 parts of polyacrylate, and 0.2 parts of PPG-24-glyceryl polyether-24 in the mixing tank in turn, and stir for 3-5 minutes;

[0039] Step 3, add 10 parts of C14-17 secondary alkyl sodium sulfonate and stir for 5-10min;

[0040] Step 4, add 0.05 part of tetrasodium edetate, 0.1 part of 1.5% effective amount of Cathone, 0.1 part of imidazolidinyl urea, 0.2 part of cocoeth-7, 0.1 part of PPG-1-PEG- 9 A mixture of lauryl glycol ether and 0.5 parts of essence, add deionized water until the sum of all components is 100 parts, and stir for 30 minutes to obtain the laundry water of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com