Propolis wine capable of enhancing immunity and preparation method thereof

A technology for propolis wine and immunity, which is applied in the field of preparing health care wine by efficiently utilizing propolis, can solve problems such as low immunity of patients, and achieve the effects of regulating immunity, improving quality of life, and enhancing curative effect of radiotherapy and chemotherapy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

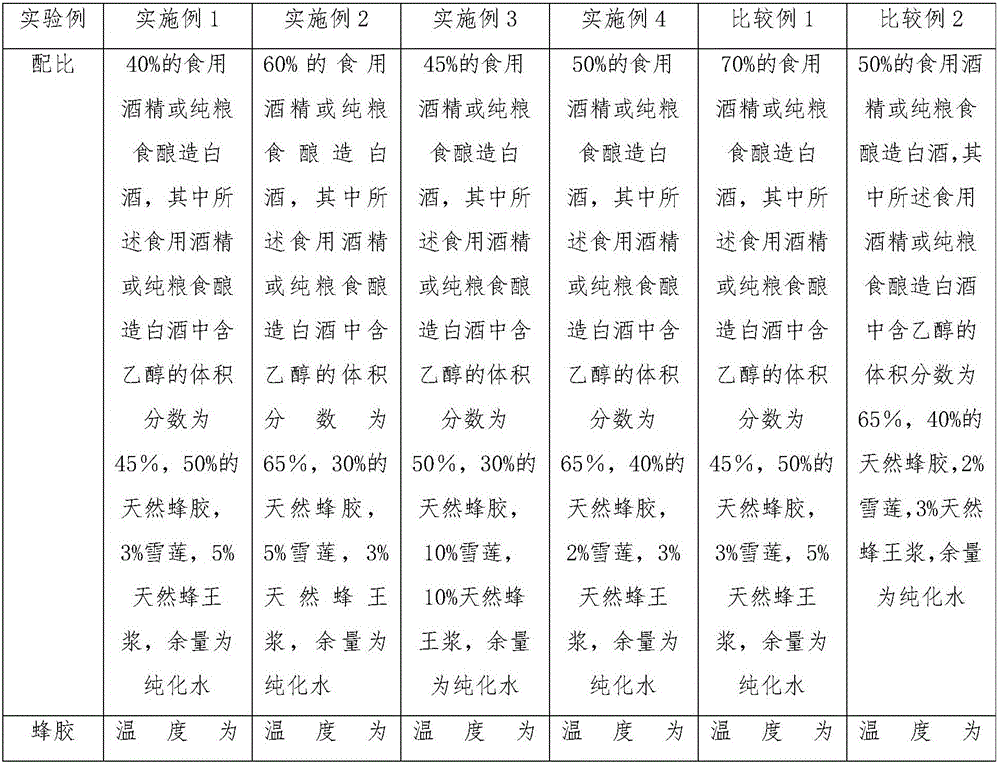

Embodiment 1

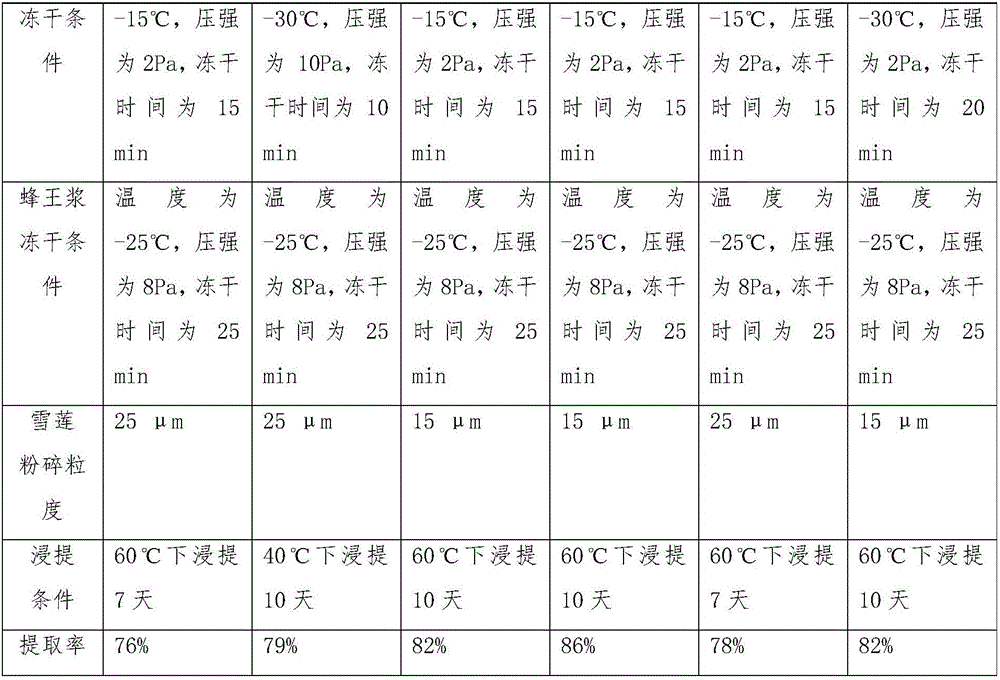

[0064] A propolis wine with improved immunity is characterized in that it comprises the following raw materials in percentage by weight: 40% edible alcohol or pure grain brewed liquor, wherein the volume fraction of ethanol in the edible alcohol or pure grain brewed liquor is 45% %, 50% natural propolis, 3% snow lotus, 5% natural royal jelly, and the balance is purified water. Concrete preparation method comprises the following steps:

[0065] 1) After the propolis is washed with water to remove impurities, it is directly freeze-dried to obtain a powdery freeze-dried powder, the propolis powder is collected and sealed, and stored in a refrigerator for later use. The freeze-drying conditions described are: the temperature is -15°C, The pressure is 2Pa, and the freeze-drying time is 15min;

[0066] 2) Freeze-dry the royal jelly directly to obtain the powdery freeze-dried powder, collect the royal jelly powder and seal it, and store it in the refrigerator for later use; the free...

Embodiment 2

[0072] A propolis wine with improved immunity is characterized in that it comprises the following raw materials in percentage by weight: 60% edible alcohol or pure grain brewed liquor, wherein the volume fraction of ethanol in the edible alcohol or pure grain brewed liquor is 65% %, 30% natural propolis, 5% snow lotus, 3% natural royal jelly, and the balance is purified water. Concrete preparation method comprises the following steps:

[0073] 1) After the propolis is washed with water to remove impurities, it is directly freeze-dried to obtain a powdery freeze-dried powder, the propolis powder is collected and sealed, and stored in a refrigerator for later use. The freeze-drying conditions described are: the temperature is -30°C, The pressure is 10Pa, and the freeze-drying time is 10min;

[0074] 2) Freeze-dry the royal jelly directly to obtain the powdery freeze-dried powder, collect the royal jelly powder and seal it, and store it in the refrigerator for later use; the fre...

Embodiment 3

[0080] A propolis wine with improved immunity is characterized in that it comprises the following raw materials in percentage by weight: 45% edible alcohol or pure grain brewed liquor, wherein the volume fraction of ethanol in the edible alcohol or pure grain brewed liquor is 50% %, 30% natural propolis, 10% snow lotus, 10% natural royal jelly, and the balance is purified water. Concrete preparation method comprises the following steps:

[0081]1) After the propolis is washed with water to remove impurities, it is directly freeze-dried to obtain a powdery freeze-dried powder, the propolis powder is collected and sealed, and stored in a refrigerator for later use. The freeze-drying conditions described are: the temperature is -15°C, The pressure is 2Pa, and the freeze-drying time is 15min;

[0082] 2) Freeze-dry the royal jelly directly to obtain the powdery freeze-dried powder, collect the royal jelly powder and seal it, and store it in the refrigerator for later use; the fre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com