Treatment method for quench boiler tube inner surface

A technology for rapidly cooling boilers and inner surfaces, applied to lighting and heating equipment, etc., can solve problems such as coking, and achieve excellent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment is used to illustrate the method provided by the present invention for treating the inner surface of the furnace tube of a quenched boiler.

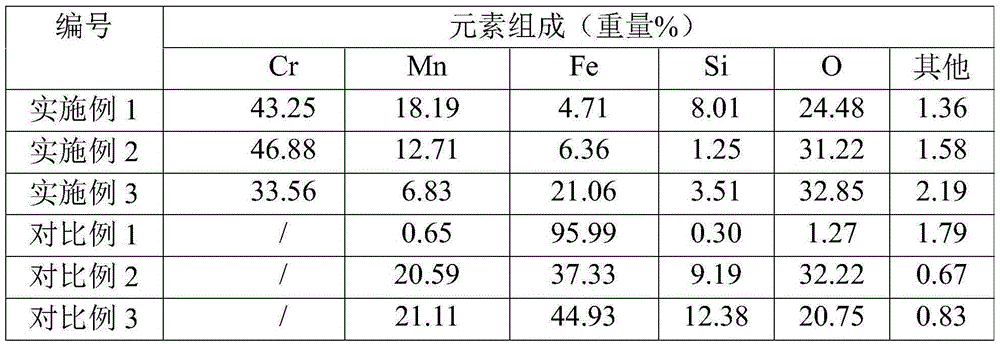

[0027] size is The inner surface of the 15Mo3 alloy furnace tube is bright and free of scale after machining. The furnace tube is processed according to the method of the present invention, specifically, hydrogen gas with a pressure of 0.1 MPa is passed into a chromic acid aqueous solution with a temperature of 10° C. and a concentration of 30% by weight to obtain hydrogen gas containing chromic acid, and then Pass it into a high-temperature furnace tube at 900°C, and treat at a constant temperature for 30 hours. After cooling, the element composition of the inner surface of the furnace tube was analyzed by X-ray energy dispersive spectrometer, and the results are shown in Table 1.

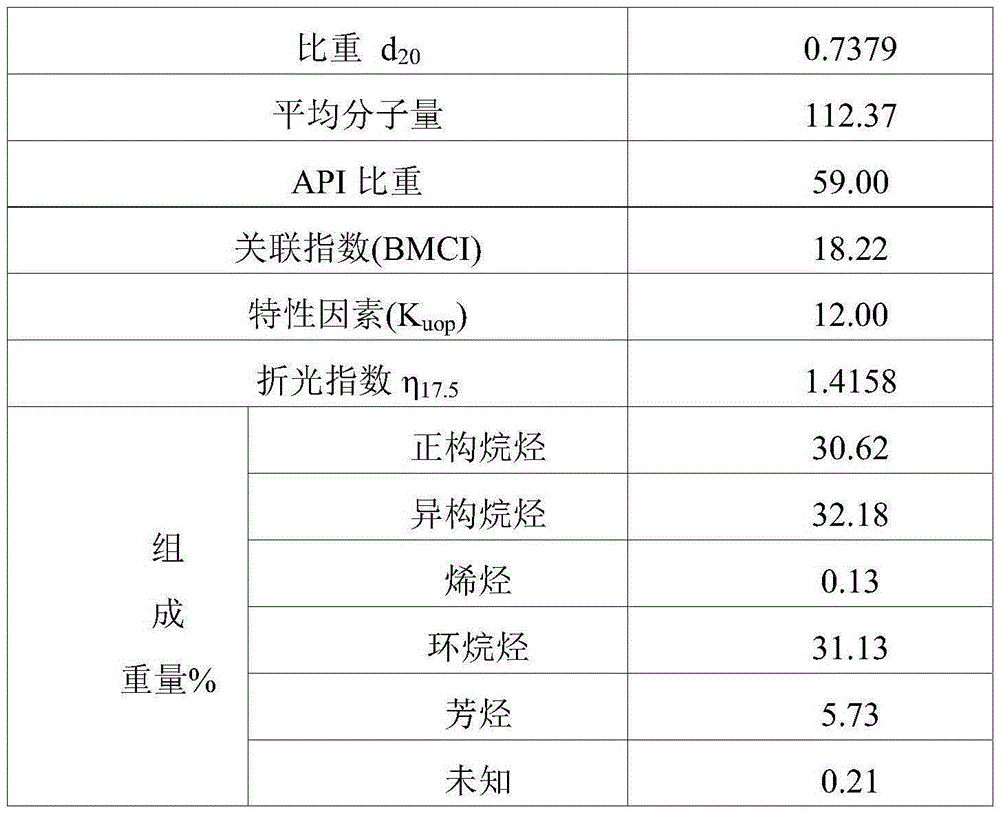

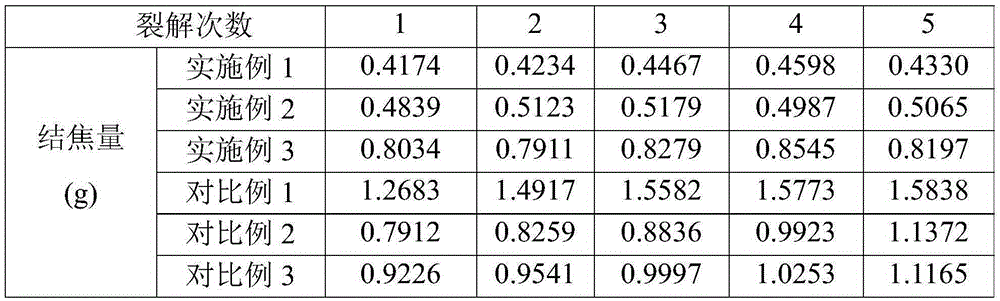

[0028] Use this furnace tube on the laboratory device of 200g / h feed rate, take naphtha (property see table 2) as cracking raw mat...

Embodiment 2

[0031] This embodiment is used to illustrate the method provided by the present invention for treating the inner surface of the furnace tube of a quenched boiler.

[0032] The size and material of the furnace tube used in this embodiment are the same as those in Embodiment 1. The furnace tube is processed according to the method of the present invention. Specifically, CO with a pressure of 0.15 MPa is introduced into a chromic acid aqueous solution having a concentration of 10% by weight at 70° C. to obtain carbon monoxide gas containing chromic acid, which is then passed through Put it into a high-temperature furnace tube at 1000°C, and treat it at a constant temperature for 20 hours. After cooling, the element composition of the inner surface of the furnace tube was analyzed by X-ray energy dispersive spectrometer, and the results are shown in Table 1.

[0033] Using the method and conditions of Example 1, the furnace tube was subjected to 5 cycles of pyrolysis and charring...

Embodiment 3

[0035] This embodiment is used to illustrate the method provided by the present invention for treating the inner surface of the furnace tube of a quenched boiler.

[0036] The size and material of the furnace tube used in this embodiment are the same as those in Embodiment 1. The furnace tube is processed according to the method of the present invention, specifically, the pressure is 0.2MPa N 2 Pass into 0 DEG C, concentration is the chromic acid aqueous solution of 20% by weight, obtain the nitrogen gas containing chromic acid, then pass it into the high-temperature furnace tube of 700 DEG C, constant temperature treatment for 60 hours. After cooling, the element composition of the inner surface of the furnace tube was analyzed by X-ray energy dispersive spectrometer, and the results are shown in Table 1.

[0037] Using the method and conditions of Example 1, the furnace tube was subjected to 5 cycles of pyrolysis and charring experiments, and the coking amounts of different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com