Low-temperature far-infrared integral electric heating tender porcelain decorative material and preparation method thereof

A decorative material, far-infrared technology, applied in the field of architectural decorative materials, can solve the problems of limited temperature adjustment, inability to realize the decorative effect of soft porcelain, and inability to adjust the ambient temperature, so as to achieve good air permeability, improve the conversion rate of electricity and heat, and improve the heat transfer rate. The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

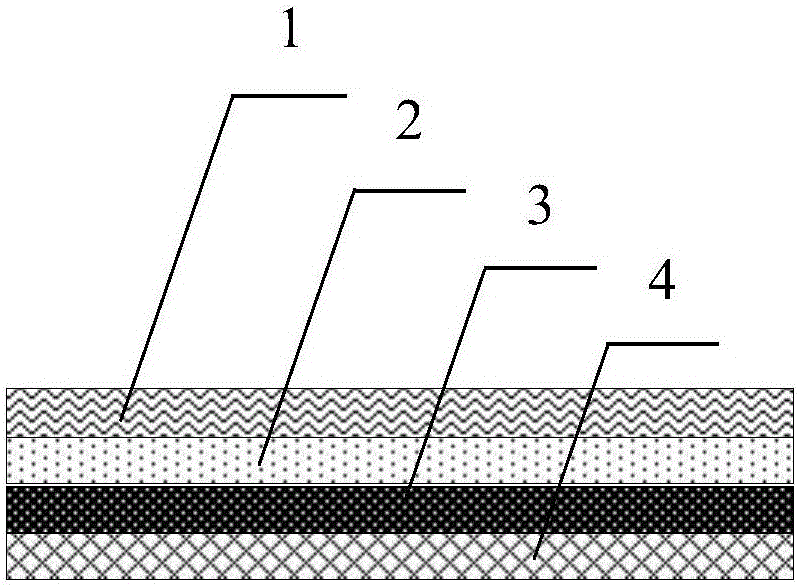

Image

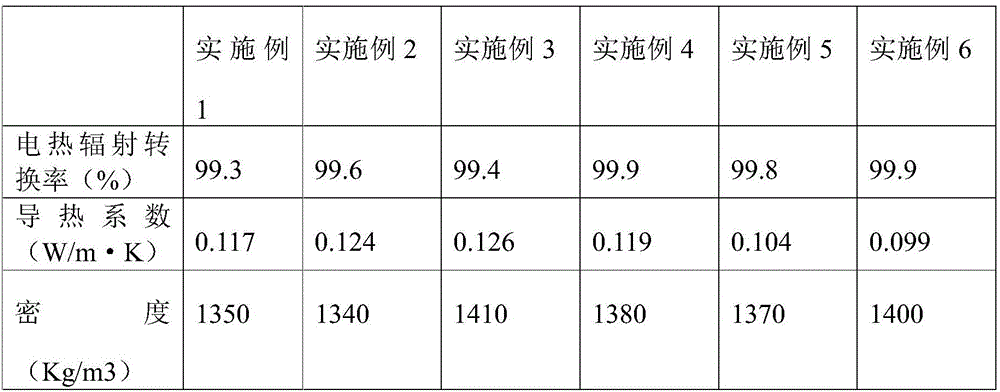

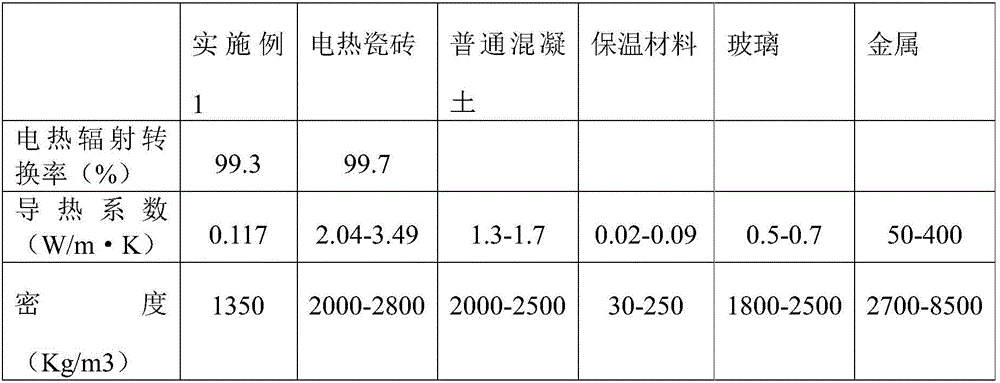

Examples

Embodiment 1

[0036] A method for preparing a low-temperature and far-infrared integrated electric heating soft porcelain decorative material, comprising the following steps:

[0037] 1) Preparation of the soft porcelain layer: First weigh 15 parts of 300-mesh medical stone powder, 60 parts of 70-mesh quartz sand, 25 parts of 325 Portland white cement, 2 parts of anatase nano-titanium dioxide, 5 parts of flame retardant melamine and 2 parts of silane coupling agent KH-550 were placed in a kneader to stir and mix evenly to obtain a mixed powder; weigh 10 parts of silicon acrylic emulsion, 0.8 parts of hydrophobic agent SEAL 80 and 25 parts of water, Place in a stirred tank and mix evenly to obtain a mixed emulsion; then add the mixed powder into the stirred tank and stir thoroughly to obtain a mixed slurry, pour the slurry into a mold, and dry it for 4 hours at a temperature of 40°C to obtain Soft porcelain layer with a thickness of 2mm;

[0038] 2) Preparation of heat-conducting waterproof...

Embodiment 2

[0042] A method for preparing a low-temperature and far-infrared integrated electric heating soft porcelain decorative material, comprising the following steps:

[0043] 1) Preparation of the soft porcelain layer: First weigh 20 parts of 250-mesh medical stone powder, 50 parts of 90-mesh quartz sand, 30 parts of 425 Portland white cement, 4 parts of rutile nano-titanium dioxide, flame retardant 10 parts of amine polyphosphate and 1.5 parts of silane coupling agent KH-560 were placed in a kneader to stir and mix evenly to obtain a mixed powder; weigh 15 parts of silicon acrylic emulsion, 0.6 parts of hydrophobic agent PHOBE H-1022 and 20 parts of water Place in a stirring tank and mix evenly to obtain a mixed emulsion; then add the mixed powder into the stirring tank and stir thoroughly to obtain a mixed slurry, pour the slurry into a mold, and dry it for 4 hours at a temperature of 50°C , to obtain a soft porcelain layer with a thickness of 2.5 mm;

[0044] 2) Preparation of ...

Embodiment 3

[0048] A method for preparing a low-temperature and far-infrared integrated electric heating soft porcelain decorative material, comprising the following steps:

[0049] 1) Preparation of the soft porcelain layer: first weigh 25 parts of 200-mesh medical stone powder, 55 parts of 100-mesh quartz sand, 20 parts of Portland white cement with a label of 525, 3.5 parts of anatase nano-titanium dioxide, 8 parts of flame retardant melamine ammonium polyphosphate and 1 part of silane coupling agent KH-570 were placed in a kneader to stir and mix evenly to obtain a mixed powder; weigh 20 parts of silicon acrylic emulsion, 0.3 parts of hydrophobic agent SEAL 80 and water 15 parts, placed in a stirred tank and mixed evenly to obtain a mixed emulsion; then the mixed powder was added to the stirred tank and stirred thoroughly to obtain a mixed slurry, which was poured into a mold and dried at a temperature of 60°C 3h, to obtain a soft porcelain layer with a thickness of 3mm;

[0050] 2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com