In-site measurement system of aspheric die and measurement method and measurement examination method of system

A measurement system and aspheric surface technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems that the measurement accuracy needs to be improved, the processing of the shearing interferogram is complex, and the in-situ measurement accuracy cannot reach the nanometer level, etc., to achieve real-time High effect of in-situ measurement, measurement accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

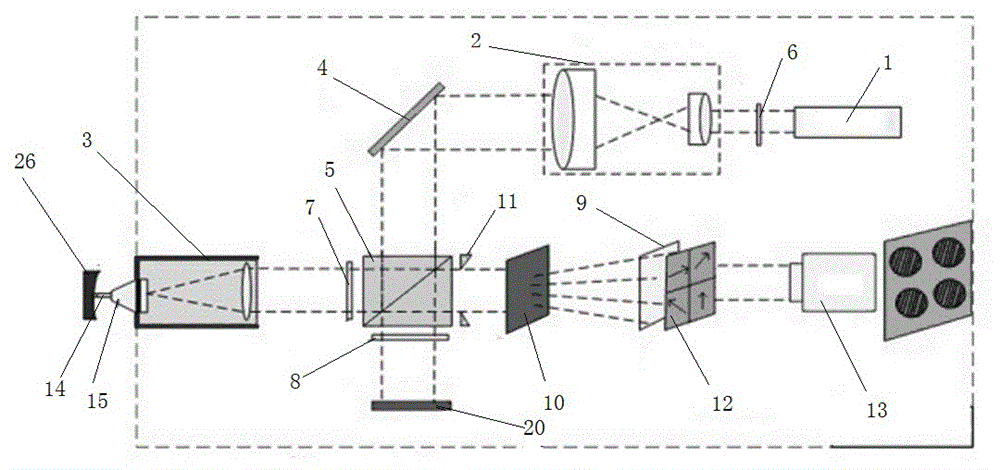

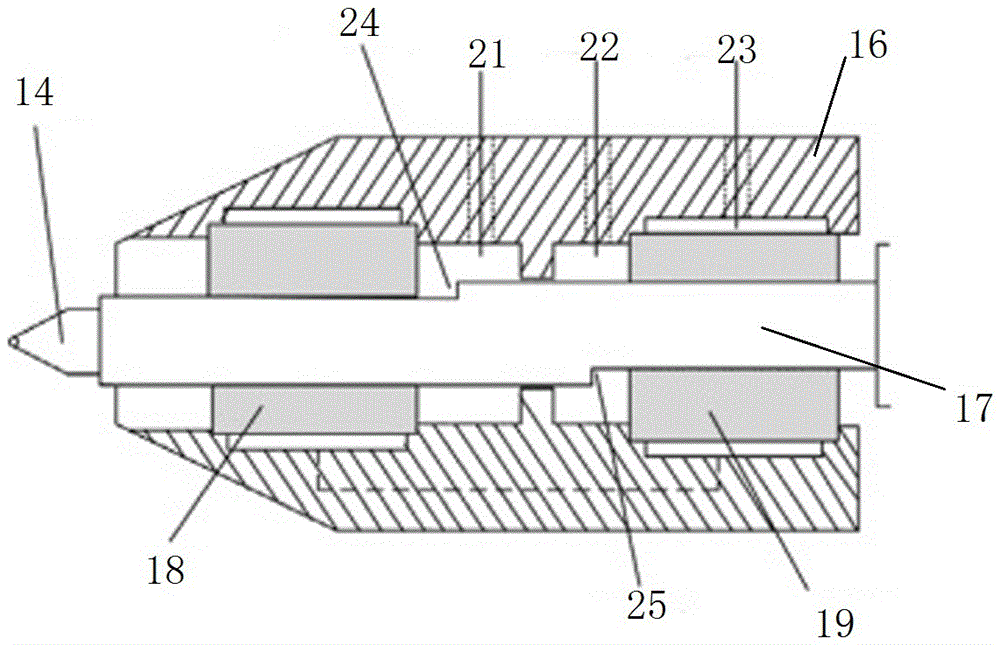

[0037] Such as figure 1 and 2 As shown, an in-situ measurement system for a hybrid aspheric lens mold includes a contact probe 14, an air bearing 15, an optical interference system, an image acquisition and processing system, and a software processing system. The optical interference system includes: semiconductor laser 1, laser beam expander system 2, cat's eye mirror 3, mirror 4, reference mirror 20, polarization beam splitter 5, 1 / 2λ wave plate 6, beam splitting grating 10, spatial filter 11 And polarizer set 12 and three 1 / 4λ glass slides. The image acquisition and processing system includes: CCD camera, image acquisition card and computer, and the software processing system includes: phase calculation module, surface coordinate conversion module, surface fitting module and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com