Defect detection method and system applied to receiver

A defect detection and receiver technology, applied in electrical components and other directions, can solve the problems of difficult to meet the long-term development of enterprises, difficulty in quality inspection of vibration parts, and low efficiency of manual inspection, so as to improve the detection efficiency and accuracy, and facilitate expansion and application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

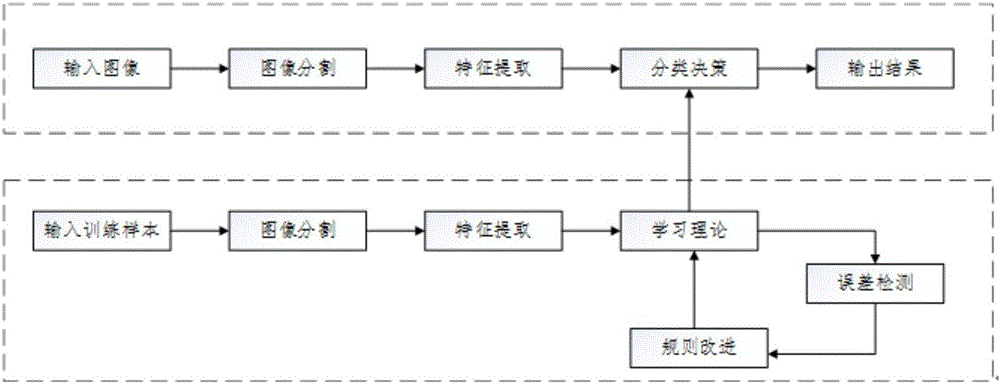

[0052] like figure 1 As shown, the defect detection method applied to the receiver of the present invention comprises the following steps:

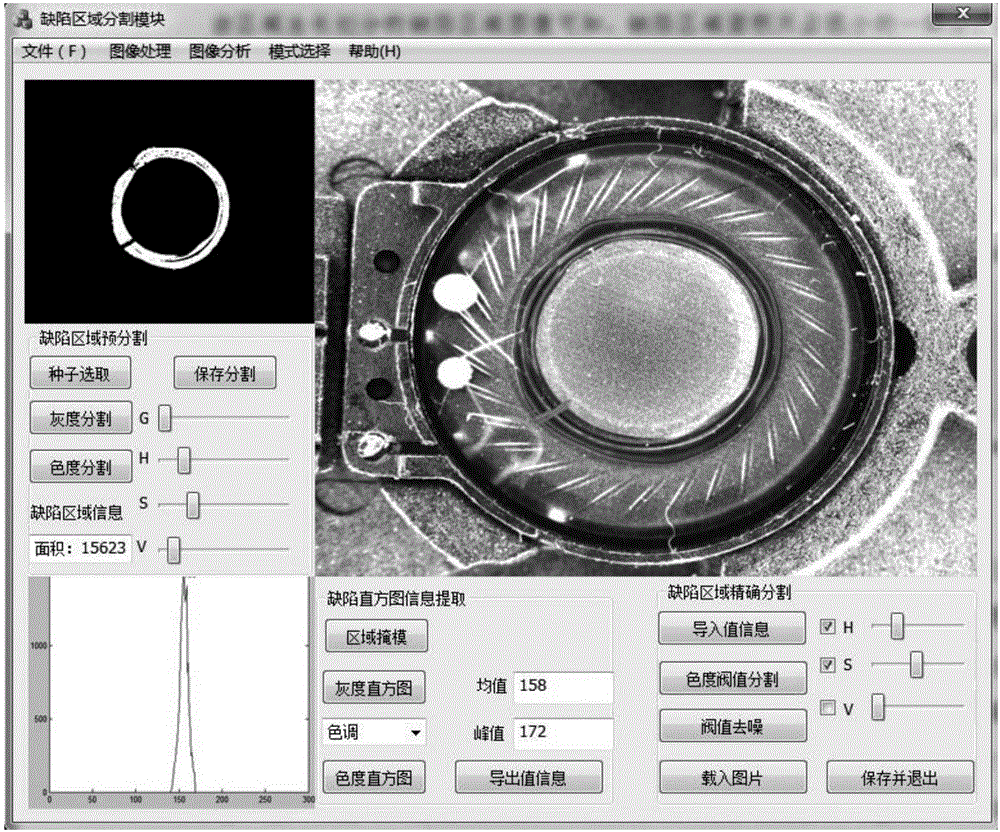

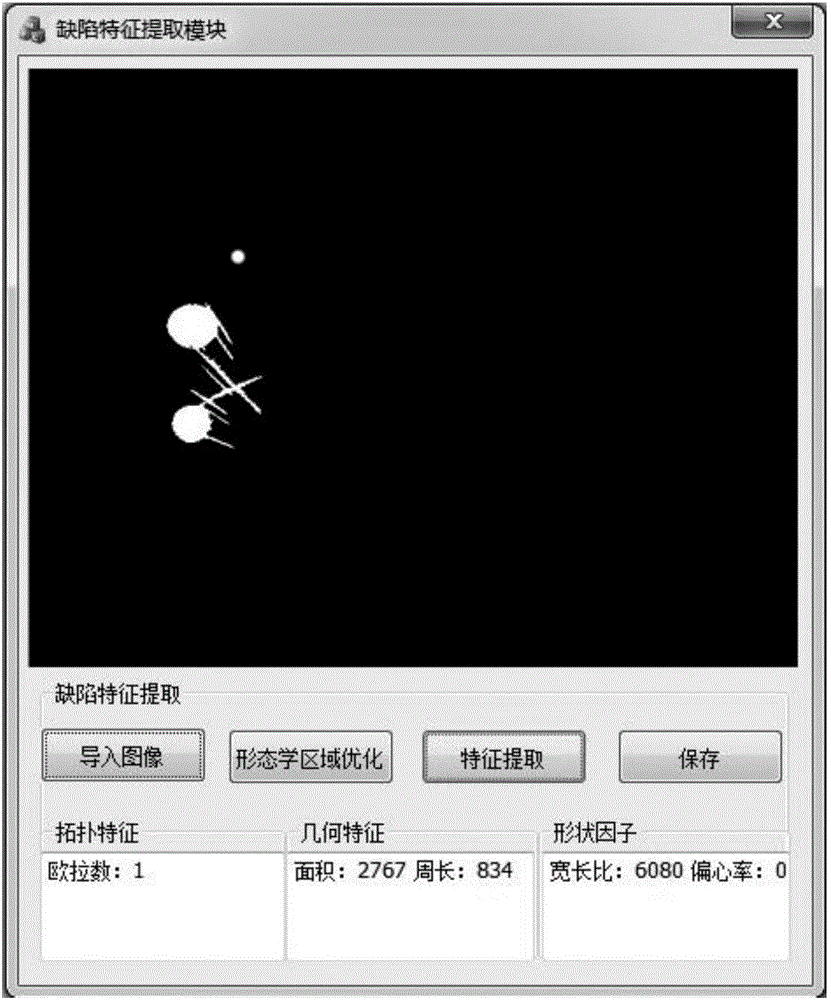

[0053] like figure 2 As shown, step S1: Defect area segmentation: input training samples through a debugging module 121, and then conduct any one or more of the receiver winding, voice coil coating, notched copper wire, and voice coil lead wire in the training sample. Segmentation to obtain the defect area, and in order to obtain complete data and realize the purpose of comprehensively detecting the receiver, the winding wire, voice coil coating, notched copper wire and voice coil lead wire of this embodiment are all subjected to defect segmentation;

[0054] Further, in step S1, the method for obtaining the defect area includes the following steps:

[0055] S1.1: Color image pre-segmentation and training: select seed growth points for region segmentation through manual interaction;

[0056] The specific method of selecting the seed g...

Embodiment 2

[0089] This embodiment is similar to Embodiment 1, the difference is:

[0090] In this embodiment, the defect region segmentation module 122, the defect feature extraction module 123 and the debugging module 121 in the online inspection system 1 are the defect region segmentation module 122, the defect feature extraction module 123 and the debugging module 121 in the offline debugging system 2, Wherein the classification identification module 14 and the defect target identification module 24 are connected by wireless and / or wired mode, in the online mode, start each module of the online detection system 1, and start each module of the offline debugging system 2 in the offline mode, At the same time, the data including the classification criteria obtained in the offline mode can be directly used in the detection in the online mode. Similarly, the detection data information collected in the online mode can be directly used in the offline mode as reference information for building...

Embodiment 3

[0092] This embodiment is similar to Embodiment 2, the difference is that:

[0093] The defect object identification module 24 and the classification identification module 14 of this embodiment are integrated in the same module, which further simplifies the system architecture.

[0094] The present invention mainly has two operating modes, which are offline debugging mode and online detection mode. In the offline debugging mode, image segmentation, feature extraction and recognition operations can be performed on images, and neural network training can be performed on the extracted features. Through continuous The optimal training result is obtained through training, so as to be used for online detection; in the online detection mode, the defect of the receiver can be detected in real time on the assembly line, and the production process can be accelerated; and the present invention mainly performs application verification for the three types of area defects of the receiver, fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com