Floating visible-light-induced photocatalyst, and preparation method and application thereof

A photocatalyst, visible light technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of floating bead structure rupture, loss of floating performance, high equipment requirements, etc. Controllable, easy to implement and industrialized utilization, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a floating visible light photocatalyst, comprising the following steps:

[0031] (1) Pretreatment of floating beads, adding fly ash floating beads to distilled water, washing at room temperature for 1h-2h, filtering, and drying at 101°C;

[0032] ⑵Bi(NO 3 ) 3 • 5H 2 O dissolved in ethylene glycol, Bi(NO 3 ) 3 • 5H 2 The mass ratio of O to ethylene glycol is 1:5 to 40. After all the solids are dissolved, add KBr or / and KI, fully stir and dissolve into a transparent mixed solution; KBr and Bi(NO 3 ) 3 • 5H 2 The molar ratio of O is 0~1:1, KI and Bi(NO 3 ) 3 • 5H 2 The molar ratio of O is 0 to 1:1, the total molar number of KBr and KI and Bi(NO 3 ) 3 • 5H 2 The molar ratio of O is 1:1;

[0033] In step (2) of the present invention, Bi(NO 3 ) 3 • 5H 2 The mass ratio of O to ethylene glycol is preferably 1:15-30.

[0034] In step (2) of the present invention, Bi(NO 3 ) 3 • 5H 2 The mass ratio of O to ethylene glycol is preferably 1...

Embodiment 2

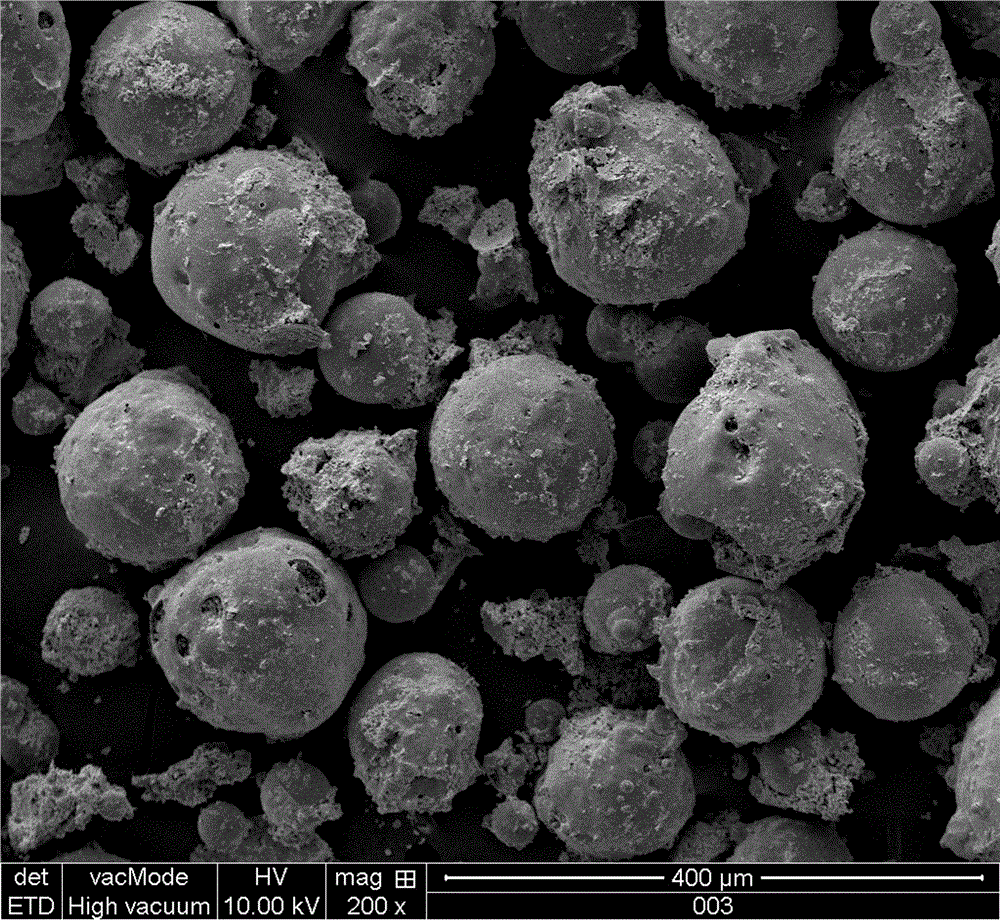

[0043] In this embodiment, fly ash floating beads (with a diameter of 20 μm to 200 μm and a specific gravity of 0.3 g / cm 3 ~0.5g / cm 3 ) into distilled water, wash at room temperature for 1-2 hours, filter, and dry at 101°C; weigh 2.8 mmo of Bi(NO 3 ) 3 • 5H 2 O was dissolved in 20mL ethylene glycol, and after all the solids were dissolved, 2.8 mmol KI was added to make KI and Bi(NO 3 ) 3 • 5H 2 O molar ratio is 1:1, fully stirred and dissolved into a transparent mixed solution; add 2.0g dried fly ash float beads to the above mixed solution, fully stir for 60min, and then add to the above mixed solution under continuous stirring at room temperature The liquid is slowly added to 35.0 wt﹪ NH 3 •H 2 O adjust the pH value of the system to 9 to obtain a white mixture; vacuum filter the milky suspension obtained in the above steps, and keep the obtained filter cake in an oven at 160 ° C for 6 hours, and then the obtained yellow-brown powder The sample was washed several times...

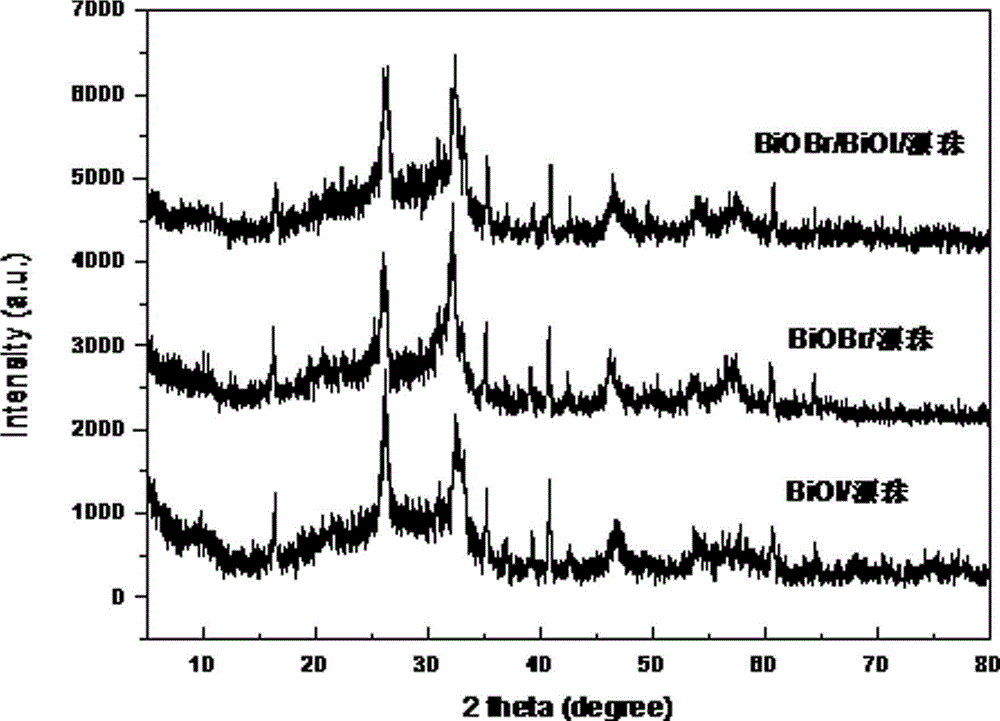

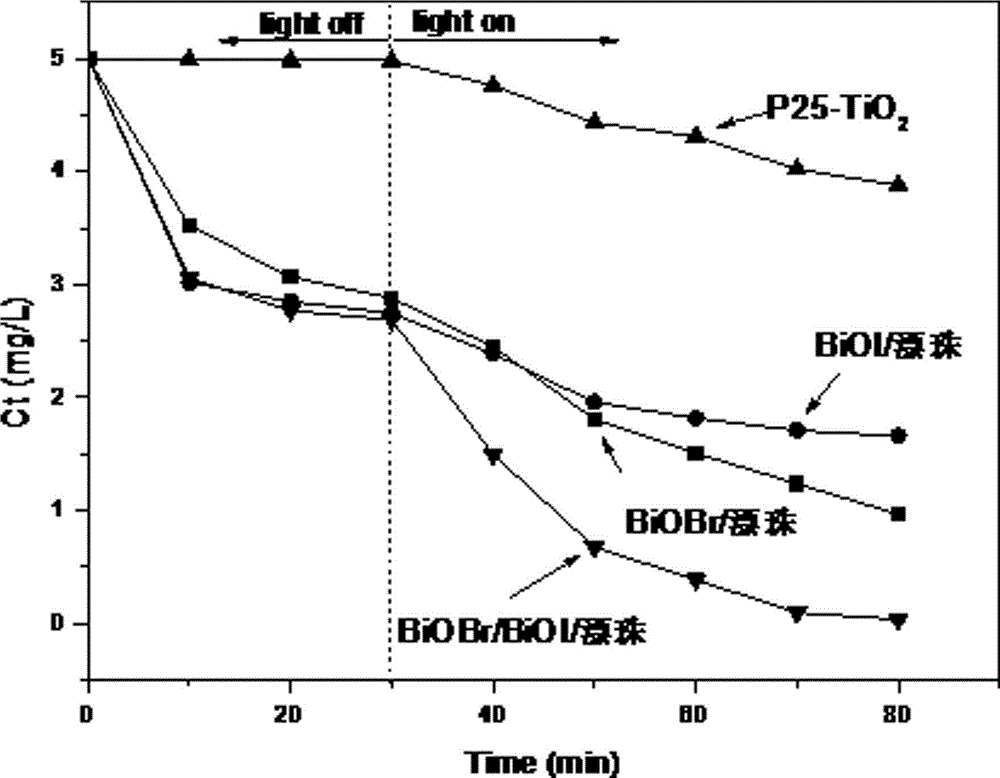

Embodiment 3

[0045] In this embodiment, fly ash floating beads (with a diameter of 20 μm to 200 μm and a specific gravity of 0.3 g / cm 3 ~0.5g / cm 3 ) into distilled water, wash at room temperature for 1-2 hours, filter, and dry at 101°C; weigh 2.8 mmo of Bi(NO 3 ) 3 • 5H 2 O was dissolved in 20mL ethylene glycol, and after the solid was completely dissolved, 1.4 mmol KBr and 1.4 mmol KI were added to make KBr and Bi(NO 3 ) 3 • 5H 2 O molar ratio is 0.5:1, while KI and Bi(NO 3 ) 3 • 5H 2 The O molar ratio is 0.5:1, the total molar number of NaBr and KI and Bi(NO 3 ) 3 • 5H 2 The molar ratio of O is 1:1, fully stirred and dissolved into a transparent mixed solution; 2.0 g of dried hollow microsphere carrier was added to the above mixed solution, and fully stirred for 60 min. Then, under continuous stirring at room temperature, slowly add 35.0 wt﹪ NH 3 •H 2 O adjust the pH value of the system to 9 to obtain a white mixture; vacuum filter the milky suspension obtained in the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com