Clay stabilizer and preparation method thereof

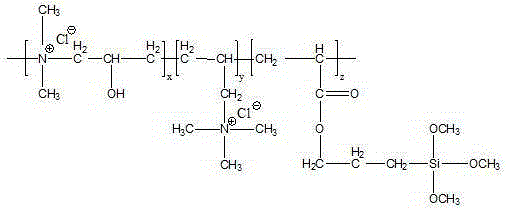

A clay stabilizer and initiator technology, applied in the field of clay stabilizer and its preparation, can solve the problems of short validity period, poor anti-swelling effect, blockage of pore roars, etc., and achieve the effect of low molecular weight and good anti-swelling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

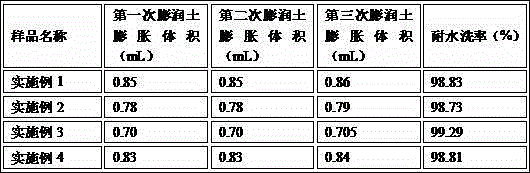

Embodiment 1

[0022] Add 60.0g of epichlorohydrin to the reactor, and control the temperature of the reactor at 20°C, add 52.5g of dimethylamine aqueous solution with a mass fraction of 40%, 4.0g of allyltrimethylammonium chloride, 6.0g of γ- (Methacryloyloxy)propyltrimethoxysilane, 1.0g diethylene glycol butyl ether, 59.5g water, add 0.55g of sodium bisulfite after 30min into the reactor, add 1.35g after 3min Ammonium persulfate is reacted at a temperature of 40° C. for 2 to 8 hours. After the reaction is completed, a clay stabilizer is obtained, and the molecular weight of the clay stabilizer is 5,000.

Embodiment 2

[0024] Add 65.0g epichlorohydrin to the reactor, the reactor temperature is controlled at 20°C, add 60.0g dimethylamine aqueous solution with a mass fraction of 40%, 6.0g allyltrimethylammonium chloride, 2.0g γ- (Methacryloyloxy)propyltrimethoxysilane, 1.2g diethylene glycol butyl ether, 206.5g water, add 0.55g sodium bisulfite after 30min into the reactor, add 1.35g after 3min Ammonium persulfate is reacted at a temperature of 40° C. for 2 to 8 hours. After the reaction is completed, a clay stabilizer is obtained, and the molecular weight of the clay stabilizer is 8,000.

Embodiment 3

[0026] Add 70.0g of epichlorohydrin to the reactor, the temperature of the reactor is controlled at 20°C, add 95.0g of dimethylamine aqueous solution with a mass fraction of 40%, 4.0g of allyltrimethylammonium chloride, 2.0g of γ- (Methacryloyloxy)propyltrimethoxysilane, 1.2g diethylene glycol butyl ether, 57.0g water, add 0.99g of sodium bisulfite after 30min into the reactor, add 2.43g after 3min Ammonium persulfate is reacted at a temperature of 40° C. for 2 to 8 hours. After the reaction is completed, a clay stabilizer is obtained, and the molecular weight of the clay stabilizer is 12,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com