A kind of drilling fluid flow pattern regulator and its preparation method

A technology of flow regulator and drilling fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as viscosity, shear force drop, poor performance of drilling fluid, and reduced carrying capacity, so as to reduce the risk of triggering Effects of temperature, increased stability, and strong suppression ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

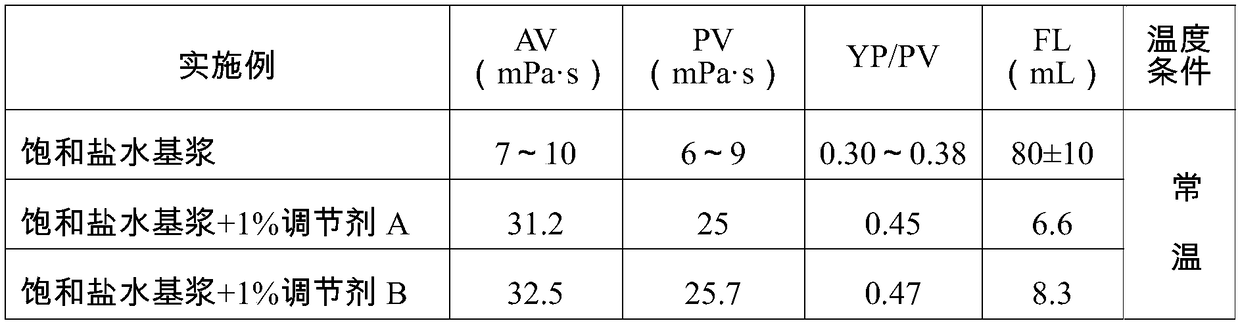

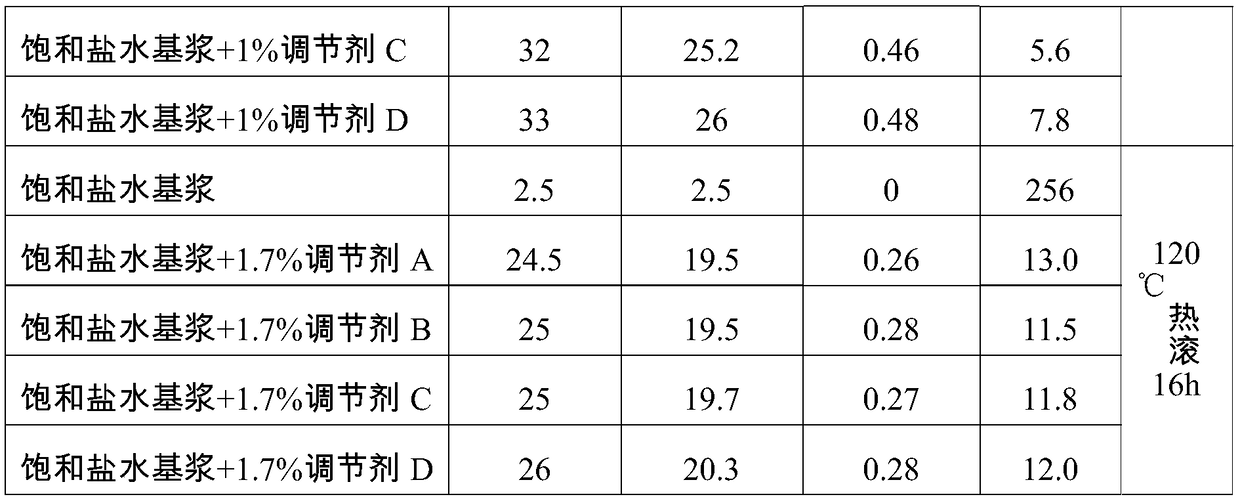

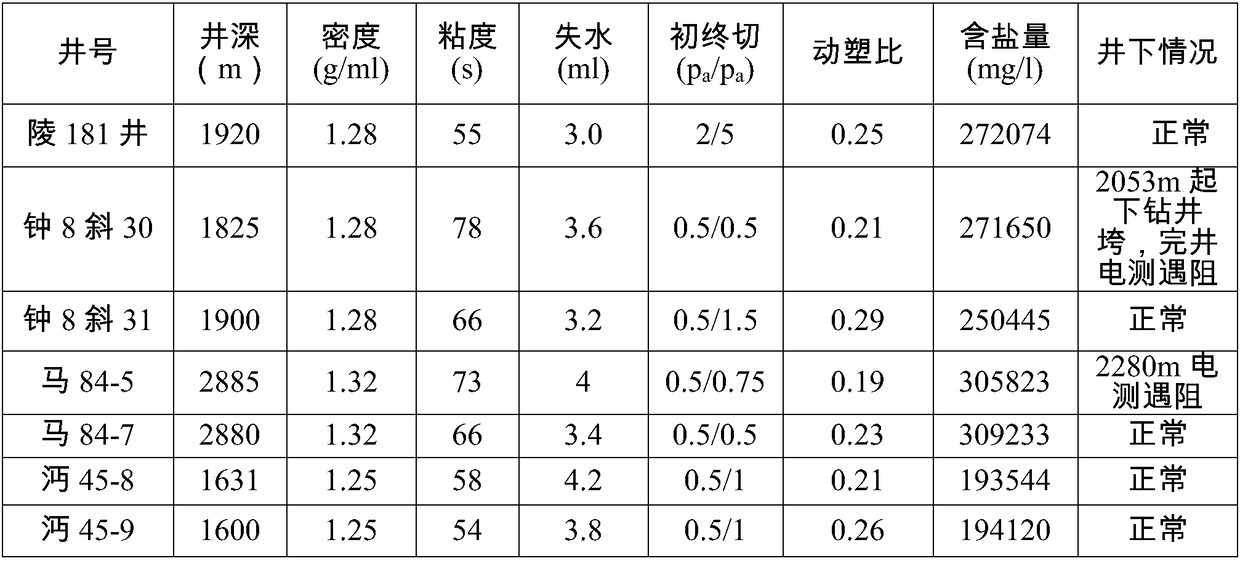

Examples

Embodiment 1

[0029] The invention provides a drilling fluid flow pattern regulator A and a preparation method thereof, comprising the steps of:

[0030] 1) the potassium hydroxide of 3.8g is dissolved with the deionized water of 10g to obtain potassium hydroxide solution;

[0031] 2) Put 3.8g of acrylic acid and 2.2g of 2-acrylamido-2-methylpropanesulfonic acid mixture into the reactor, add potassium hydroxide solution dropwise to the reaction, and adjust the pH to 6.5 with ammonia water after the dropwise addition ;

[0032] 3) Add 15g of acrylamide, 1g of acryloyloxyethyltrimethylammonium chloride, 0.3g of urea, 3ppm transition metal catalyst, and 34g of deionized water into the reactor, and mix them uniformly The solution is poured into a metal polymerization tank with an isolation membrane;

[0033] 4) add the initiator of 160ppm, the blowing agent of 0.53g in the polymerization tank, obtain the copolymerization rubber block after airtight reaction 2h under the protection of nitrogen...

Embodiment 2

[0036] The invention provides a drilling fluid flow pattern regulator B and a preparation method thereof, comprising the steps of:

[0037] 1) the potassium hydroxide of 3.5g is dissolved with the deionized water of 10g to obtain potassium hydroxide solution;

[0038] 2) Put 2.27g of acrylic acid and 6.53g of 2-acrylamido-2-methylpropanesulfonic acid mixture into the reactor, add potassium hydroxide solution dropwise to the reaction, and adjust the pH to 6.3 with ammonia water after the dropwise addition ;

[0039] 3) Add 15g of acrylamide, 1g of acryloyloxyethyltrimethylammonium chloride, 0.3g of urea, 3ppm transition metal catalyst, and 34g of deionized water into the reactor, and mix them uniformly The solution is poured into a metal polymerization tank with an isolation membrane;

[0040] 4) add the initiator of 160ppm, the blowing agent of 0.53g in the polymerization tank, obtain the copolymerization rubber block after airtight reaction 3h under the protection of nitrog...

Embodiment 3

[0043] The invention provides a drilling fluid flow pattern regulator C and a preparation method thereof, comprising the steps of:

[0044] 1) the potassium hydroxide of 3.5g is dissolved with the deionized water of 10g to obtain potassium hydroxide solution;

[0045] 2) Put 3.8g of acrylic acid and 2.2g of 2-acrylamido-2-methylpropanesulfonic acid mixture into the reactor, add potassium hydroxide solution dropwise to the reaction, and adjust the pH to 6 with ammonia water after the dropwise addition ~7;

[0046] 3) Add 15g of acrylamide, 1.2g of acryloyloxyethyltrimethylammonium chloride, 0.3g of urea, 3ppm transition metal catalyst, and 34g of deionized water into the reactor, and mix the reactor Pour the solution in the metal polymerization tank with an isolation membrane;

[0047] 4) add the initiator of 160ppm, the blowing agent of 0.53g in the polymerization tank, obtain the copolymerization rubber block after airtight reaction 3h under the protection of nitrogen;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com