Polyphenylene ether resin composition and prepreg containing same, laminated board and printed-circuit board

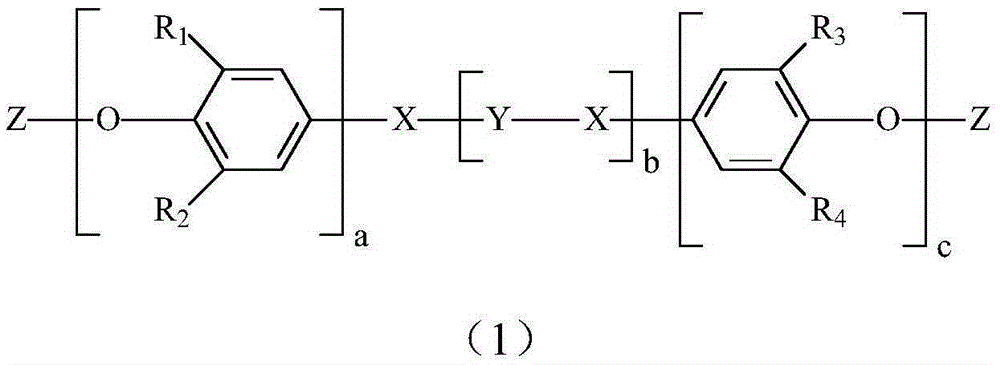

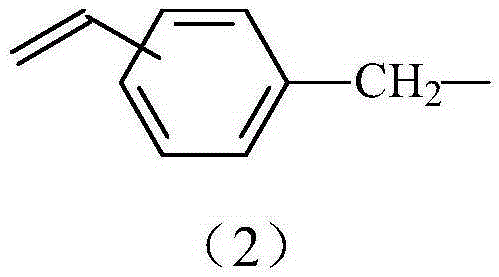

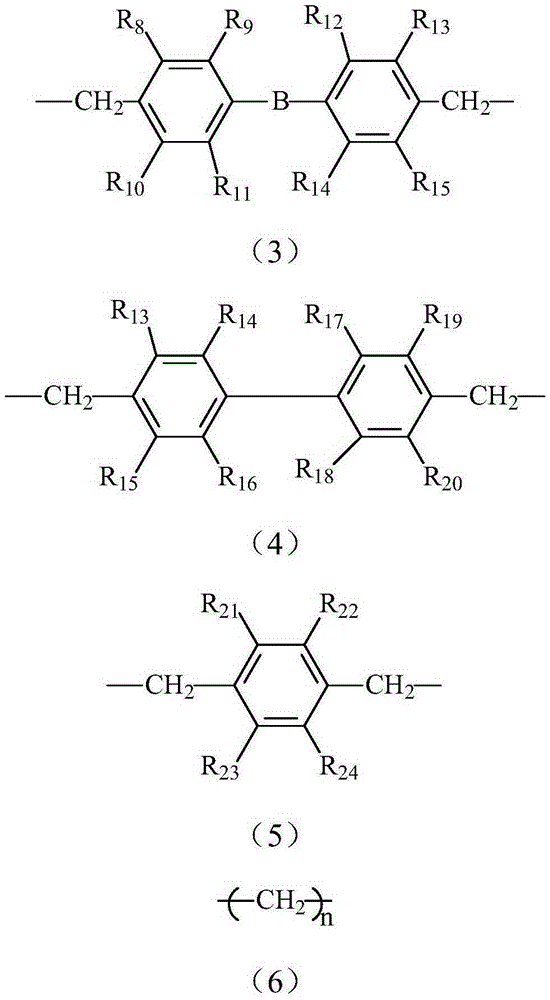

A technology of polyphenylene ether resin and composition, applied in the fields of laminates and printed circuit boards, prepregs, and polyphenylene ether resin compositions, can solve the problem of poor resistance to thermal oxidation aging, low dielectric constant, low dielectric Loss and other issues, to achieve the effect of good thermal oxidation resistance, small absolute value of change, and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0063] Synthesis of Pentafunctional Vinylbenzyl Ether Modified Thermosetting Polyphenylene Ether Resin VBMP-1:

[0064] Add 32.4g of methylphenol, 24.4g of 2,6-dimethylphenol, 50.0g of formaldehyde solution (the content of formaldehyde is (24wt%)), 1.0g of aqueous hydrochloric acid solution (the content of HCL is 32wt%), and add the In a four-necked reaction flask, heat it to 80-90°C, wash it with water three times after reacting for 6 hours, and distill off the water under reduced pressure. Cool to 50°C and add 125g of polyphenylene ether (number average molecular weight = 2500), 300g of toluene, and heat to 80~ At 90°C, add 2 g of benzoyl peroxide in batches, wash with water three times after reacting for 8 hours, distill under reduced pressure to remove toluene and water, and the number average molecular weight of polyphenylene ether detected by GPC is 1340. Dissolve the obtained polyphenylene ether in toluene solution (the polyphenylene ether content is 40wt%), add 30g (0....

preparation example 2

[0066] Synthesis of Pentafunctional Vinylbenzyl Ether Modified Thermosetting Polyphenylene Ether Resin VBMP-2:

[0067] Add 32.4g of methylphenol, 24.4g of 2,6-dimethylphenol, 50.0g of formaldehyde solution (the content of formaldehyde is (24wt%)), 1.0g of aqueous hydrochloric acid solution (the content of HCL is 32wt%) is equipped with mechanical stirring, and the cooling tube In a four-necked reaction flask, heat it to 80-90°C, wash it with water three times after reacting for 6 hours, and remove the water by distillation under reduced pressure. Cool to 50°C and add 125g of polyphenylene ether (number average molecular weight = 10000), 300g of toluene, and heat to 80~ At 90°C, add 2 g of benzoyl peroxide in batches, wash with water three times after reacting for 8 hours, distill under reduced pressure to remove toluene and water, and the number average molecular weight of polyphenylene ether detected by GPC is 1340. Dissolve the obtained polyphenylene ether in toluene solutio...

preparation example 3

[0069] Synthesis of Pentafunctional Vinylbenzyl Ether Modified Thermosetting Polyphenylene Ether Resin VBMP-3:

[0070] Add 32.4g of methylphenol, 24.4g of 2,6-dimethylphenol, 50.0g of formaldehyde solution (the content of formaldehyde is (24wt%)), 1.0g of aqueous hydrochloric acid solution (the content of HCL is 32wt%) is equipped with mechanical stirring, and the cooling tube In a four-necked reaction flask, heat it to 80-90°C, wash it with water three times after reacting for 6 hours, and remove the water by distillation under reduced pressure. Cool to 50°C and add 125g of polyphenylene ether (number average molecular weight = 15000), 300g of toluene, and heat to 80~ At 90°C, add 2 g of benzoyl peroxide in batches, wash with water three times after reacting for 8 hours, distill under reduced pressure to remove toluene and water, and the number average molecular weight of polyphenylene ether detected by GPC is 1340. Dissolve the obtained polyphenylene ether in toluene solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com