Method for inhibiting bonding of pellets in COREX shaft furnace

A technology of pelletizing and shaft furnace, which is applied in the field of suppressing pellet bonding in the COREX shaft furnace, and can solve the problems of affecting the forward movement of the pre-reduction shaft furnace, reducing the efficiency of equipment use, and poor air permeability of the material column, so as to ensure the strength and improve the utilization Efficiency, reduce the effect of pulverization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

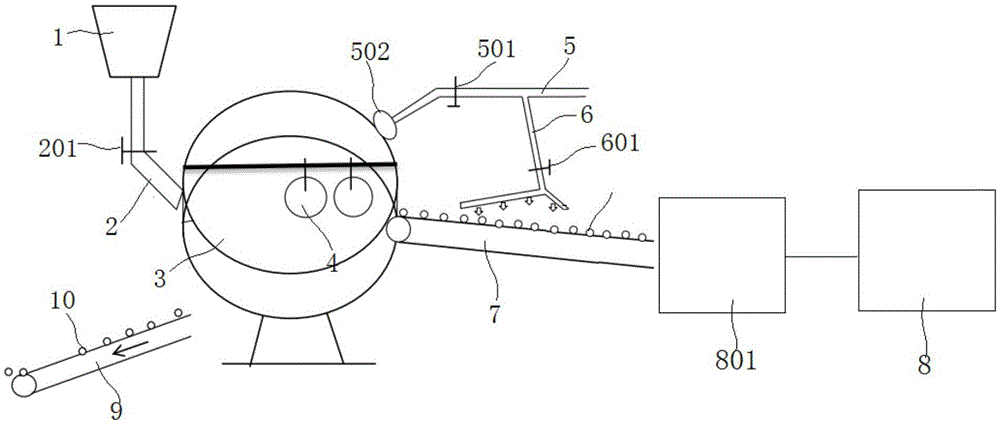

[0041] Such as figure 2 As shown, a production device for COREX coated pellets in this embodiment includes a roasting furnace 8, a pelletizing machine 3, a coating material tank 1 and a water inlet pipe 5, wherein the roasting furnace 8 is connected with cooked pellet storage The area 801 is connected, and the cooked ball storage area 801 is connected with the pelletizing machine 3 through the feeding conveyor belt 7, and the pelletizing machine 3 in this embodiment adopts a disc pelletizing machine. The coating material tank 1 is connected to the pelletizing machine 3 through the feeding pipe 2, and the coating material tank 1 is equipped with a solid inhibitor Ca(OH) 2 , and a feeding control valve 201 is provided on the feeding pipe 2 . The nozzle 502 at the end of the water inlet pipe 5 is located above the pelletizer 3, and the end of the water inlet pipe 5 near the nozzle 502 is provided with a flow valve 501, and the nozzle 502 is an atomizing nozzle. The above-menti...

Embodiment 2

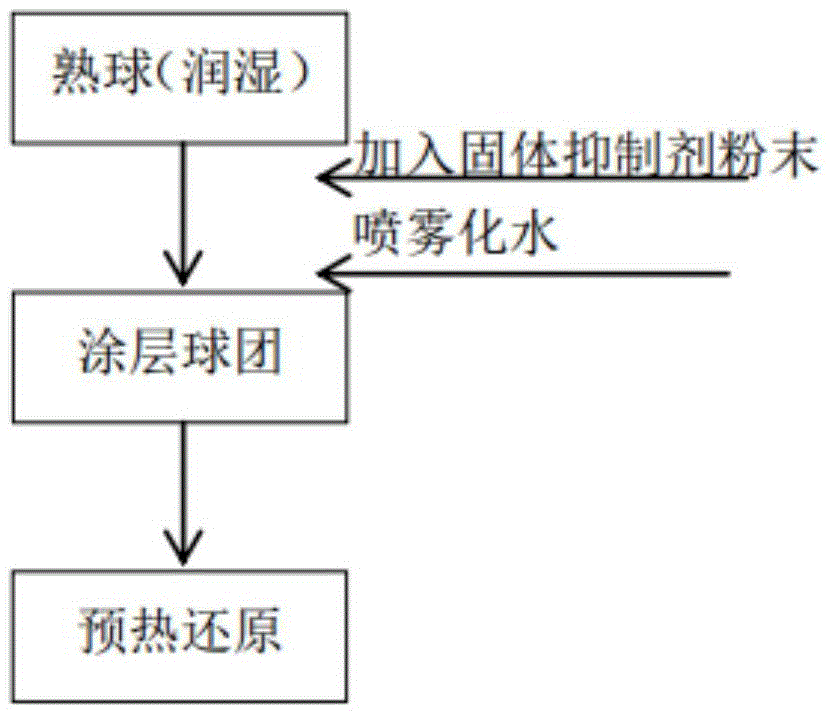

[0056] A method of inhibiting pellet bonding in the COREX shaft furnace in this embodiment is to prepare a layer of solid inhibitor on the surface of the pellets after roasting the green pellets to make coated pellets, so that the COREX shaft furnace can be effectively improved. The sticking problem of pellets in the process is beneficial to the smooth operation of the pre-reduction shaft furnace, which improves the utilization efficiency of the COREX shaft furnace equipment and reduces the production cost. The specific steps are:

[0057] (1) Preheat the prepared green pellets at 1000°C for 14 minutes, and then bake them at 1300°C for 13 minutes to form finished oxidized pellets. The main components of the green pellets in this example are shown in Table 2. When the green pellets are formed into pellets, the amount of bentonite added is 1.3%, the water content of the obtained green pellets is 8.0%, and the pelletizing time is 10 minutes.

[0058] The main component (%) of ta...

Embodiment 3

[0068] A method of inhibiting pellet bonding in the COREX shaft furnace in this embodiment is to prepare a layer of solid inhibitor on the surface of the pellets after roasting the green pellets to make coated pellets, so that the COREX shaft furnace can be effectively improved. The sticking problem of pellets in the process is beneficial to the smooth operation of the pre-reduction shaft furnace, which improves the utilization efficiency of the COREX shaft furnace equipment and reduces the production cost. The specific steps are:

[0069] (1) Preheat the prepared green pellets at 900°C for 15 minutes, and then bake them at 1320°C for 12 minutes to form finished oxidized pellets. The main components of the green pellets in this example are shown in Table 4. When the green pellets are formed into pellets, the amount of bentonite added is 1.7%, the water content of the obtained green pellets is 8.0%, and the pelletizing time is 15 minutes.

[0070] The main component (%) of tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com