Etching liquid composition for copper-based metal film, array substrate using the etching liquid composition for display device and manfuacutring method of the etching liquid composition

A technology for array substrates and display devices, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as increased process time, reduced etching straightness, and poor etching contours, and achieves excellent etching contours, The effect of a small amount of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0117] Experimental example 1. Measurement of etching profile and etching straightness

[0118] In the experimental equipment (model name: ETCHER (TFT), SEMES company) of spraying type etching mode, put respectively the etchant composition of above-mentioned embodiment 1~5 and comparative example 1~5, set the temperature of etchant composition to Heating was performed at about 33°C. Although the total etching time may vary depending on the etching temperature, it is generally performed on the order of 50 to 80 seconds in the LCD etching process.

[0119] Put the substrate in, start spraying, take it out after 50 to 80 seconds of etching time, wash it with deionized water, and dry it with a hot air drying device. Cut the substrate after cleaning and drying. The cross section was measured with a scanning electron microscope (SEM: Hitachi product, model name S-4700). The results are described in Table 2 below.

[0120]

[0121] ○: good

[0122] △: Normal

[0123] Х: bad...

experiment example 2

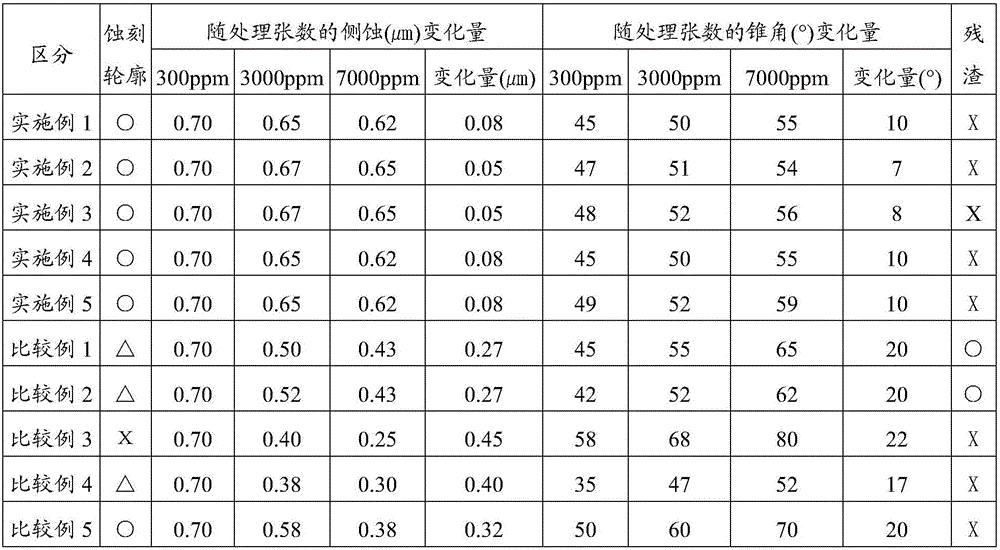

[0125] Experimental example 2. The change of side erosion and the measurement of cone angle with the number of substrates processed

[0126] In the experimental equipment (model name: ETCHER (TFT), SEMES company) of spraying type etching mode, put respectively the etchant composition of above-mentioned embodiment 1~5 and comparative example 1~5, set the temperature of etchant composition to Heating was performed at about 33°C. Although the total etching time may vary depending on the etching temperature, it is generally performed on the order of 50 to 80 seconds in the LCD etching process.

[0127] Regarding the measurement of the side erosion change and the cone angle measurement with the number of sheets being processed, the Mo-Ti and Cu powder is thrown in and performed. In the case of 300ppm, put in 150ppm of Mo-Ti powder and 150ppm of Cu powder; in the case of 3,000ppm, put in 1,500ppm of Mo-Ti powder and 1,500ppm of Cu powder; ppm and Cu powder 3,500ppm, experiment....

experiment example 3

[0132] Experimental example 3. Residue measurement

[0133] In the experimental equipment (model name: ETCHER (TFT), SEMES company) of spraying type etching mode, put respectively the etchant composition of above-mentioned embodiment 1~5 and comparative example 1~5, set the temperature of etchant composition to Heating was performed at about 33°C. Although the total etching time may vary depending on the etching temperature, it is generally performed on the order of 50 to 80 seconds in the LCD etching process.

[0134] Put the substrate in, start spraying, take it out after 50 to 80 seconds of etching time, wash it with deionized water, dry it with a hot air drying device, and remove the photoresist with a photoresist stripper (PR stripper) . After washing and drying, use a scanning electron microscope (SEM; model name: S-4700, manufactured by HITACHI Corporation) to measure the residue, which is a phenomenon that the metal film remains without being etched, in the part no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com