Phase change material for phase change memory and preparation method thereof

A phase-change memory and phase-change material technology, applied in the field of microelectronics, can solve problems such as poor data retention, low crystallization temperature, and slow phase change speed, achieve phase change speed and fatigue cycle characteristics, and realize information storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

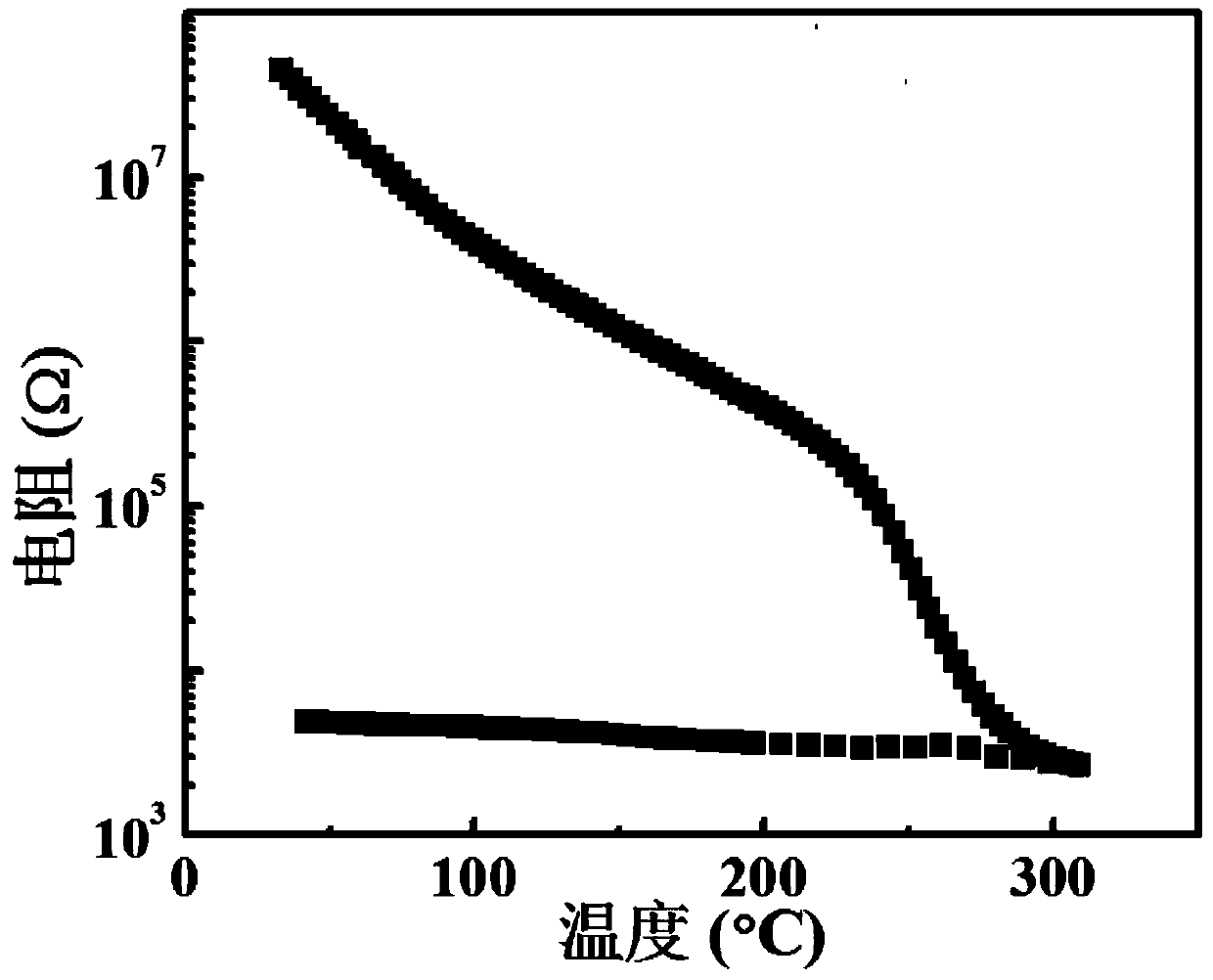

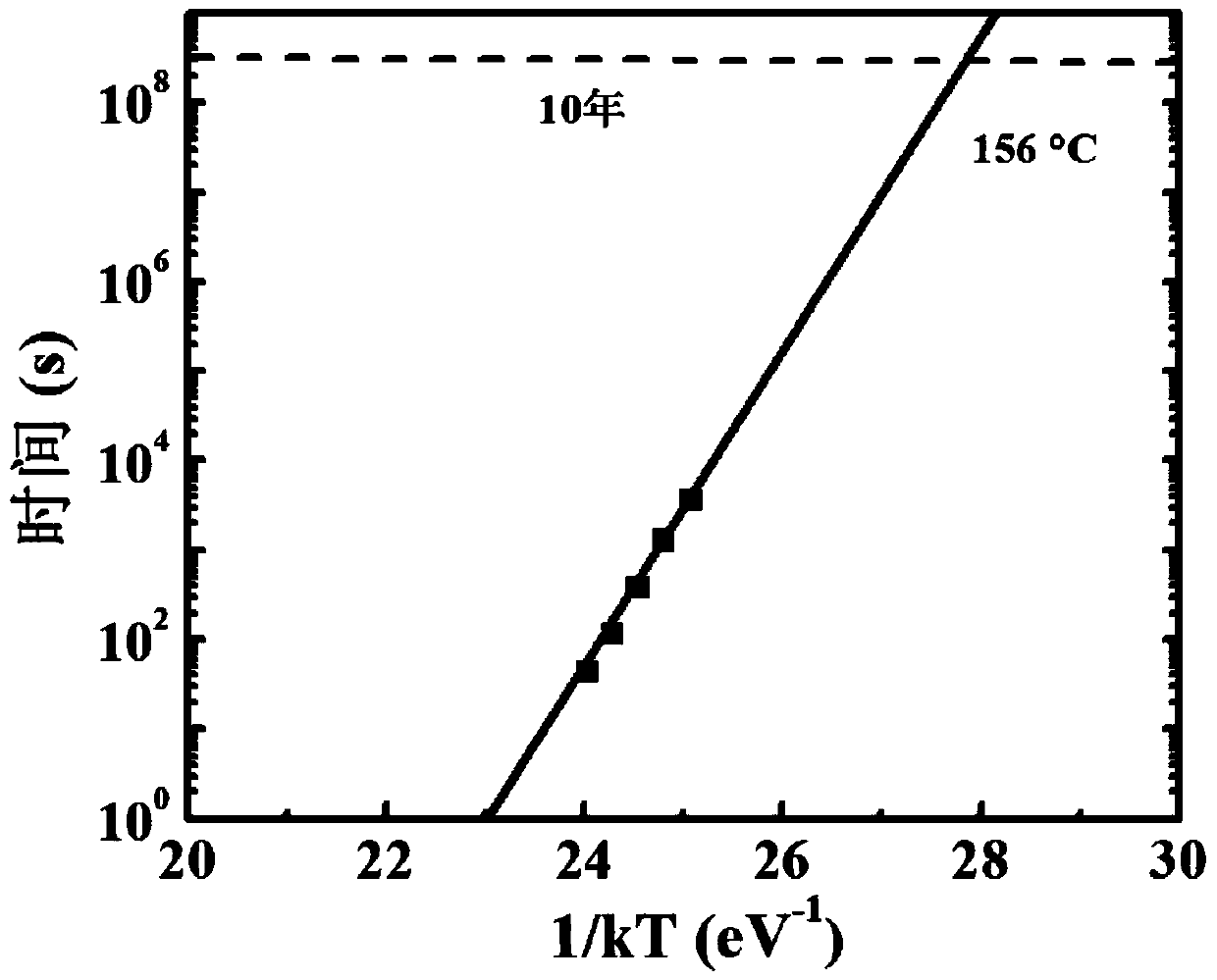

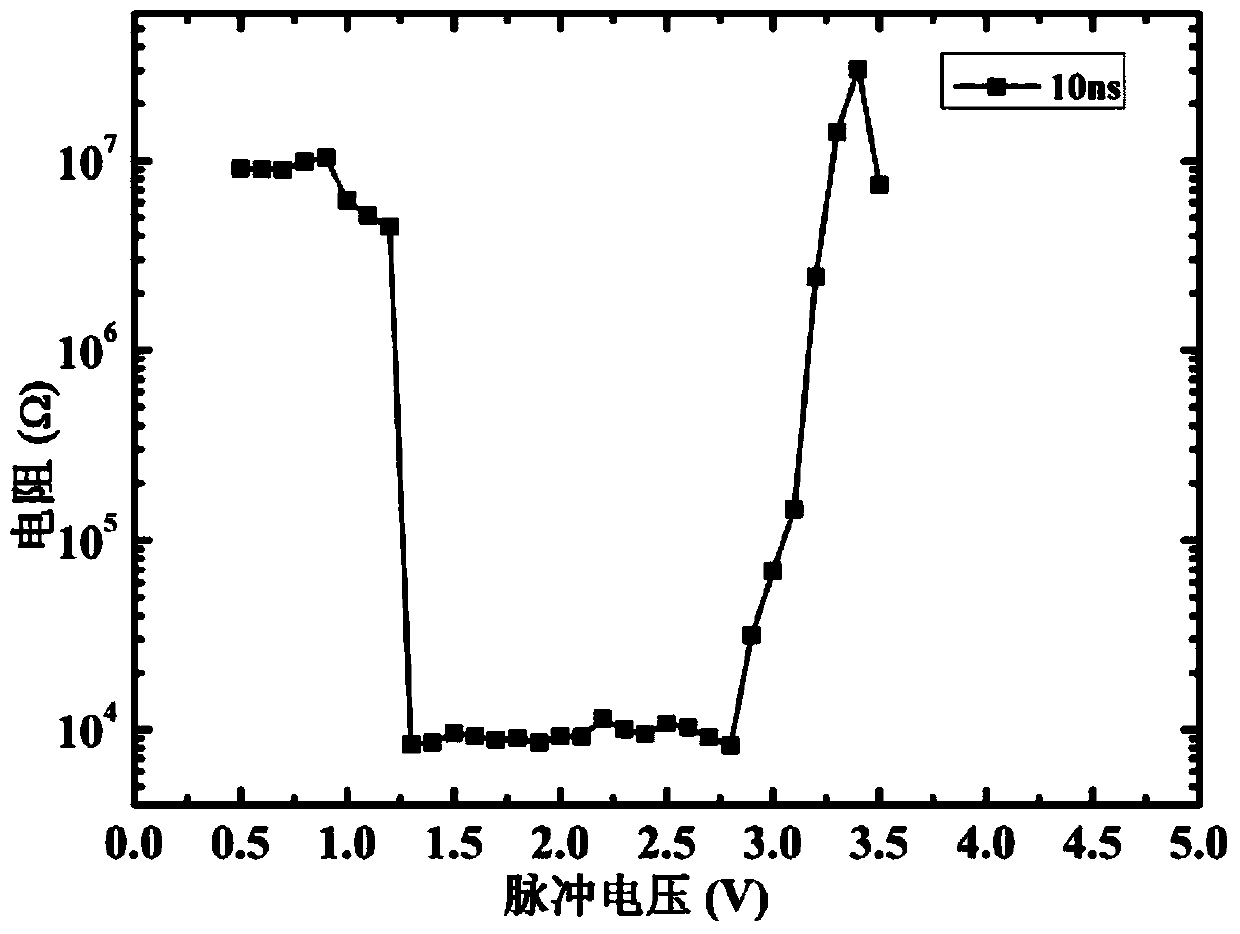

[0032] This embodiment provides a Sc for phase change memory 100-x-y-z Ge x Sb y Te z Phase change material system, wherein, the phase change material system is in Sb 2 Te 3 It is formed by doping Sc on the basis of the phase change material system, and its general chemical formula is Sc 100-x-y- z Ge x Sb y Te z , where x=0, 0<y≤80.

[0033] The phase change material realizes reversible phase transition through electric drive, laser pulse drive or electron beam drive, and realizes the function of data storage.

[0034] Specifically, in this embodiment, the Sc 100-x-y-z Ge x Sb y Te z The general chemical formula of phase change materials is Sc 5 Sb 38 Te 57 , and using Sb 2 Te 3 Co-sputtering of alloy target and Sc elemental target to obtain Sc 5 Sb 38 Te 57 For thin films, different thicknesses of materials can be controlled by controlling the sputtering time. In this embodiment, sputtering is under 99.999% argon atmosphere, Sb 2 Te 3 The alloy target...

Embodiment 2

[0040] This embodiment adopts basically the same technical solution as Embodiment 1, the difference is that the Sb in Embodiment 1 2 Te 3 Alloy target changed to Sb 2 Te alloy target. The remaining steps are exactly the same as in Example 1. The electrical properties of the obtained corresponding devices can also achieve similar effects.

Embodiment 3

[0042] This embodiment provides a Sc for phase change memory 100-x-y-z Ge x Sb y Te z A phase change material system, wherein the phase change material system is a structure Sc 2 Te 3 -Sb 2 Te 3 Pseudo binary phase change material system, its chemical formula is Sc 100-x-y- z Ge x Sb y Te, where x=0, 0<y≤80.

[0043] The phase change material realizes reversible phase transition through electric drive, laser pulse drive or electron beam drive, and realizes the function of data storage.

[0044] Specifically, in this embodiment, the Sc 100-x-y-z Ge x Sb y Te z The general chemical formula of phase change materials is Sc 20 Sb 20 Te 60 , and adopt the co-sputtering method of Sc simple substance target, Sb simple substance target and Te simple substance target to obtain Sc 20 Sb 20 Te 60 For thin films, different thicknesses of materials can be controlled by controlling the sputtering time. In this embodiment, the sputtering is carried out under a 99.999% arg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com