Oil-water separation device and oil-water separation method

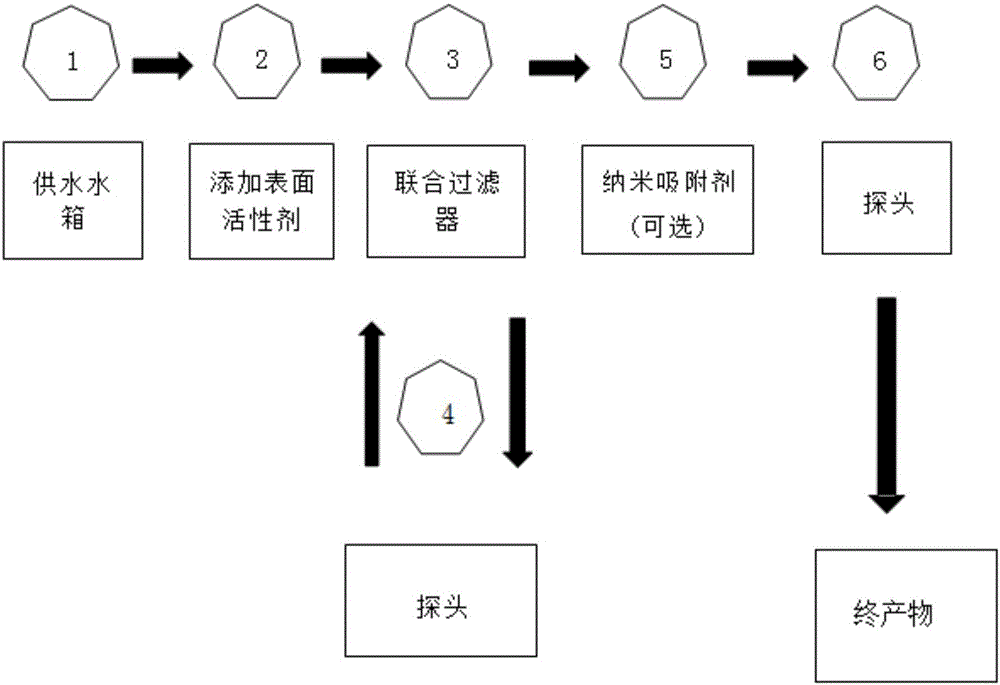

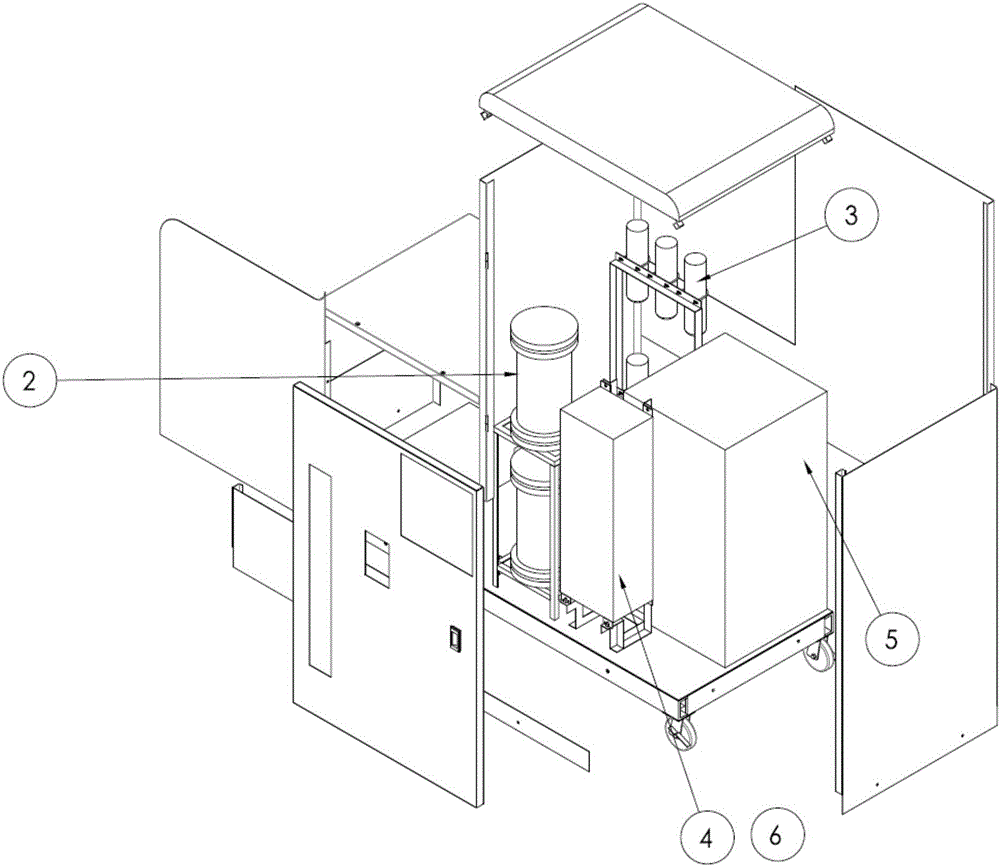

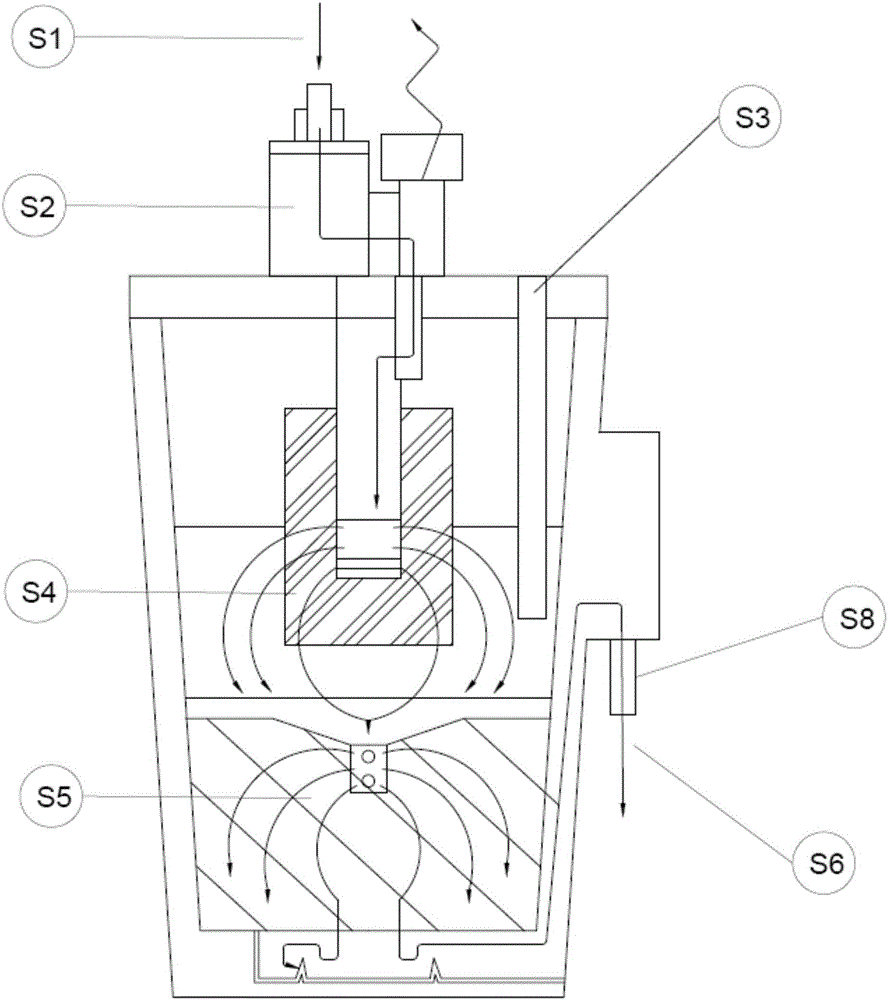

An oil-water separation device and oil-water separation technology are applied in separation methods, liquid separation, grease/oily substance/floating matter removal devices, etc., and can solve the problems of large dosage of chemicals, large amount of waste residues, long contact time replacement, etc. Achieve the effect of high oil-water separation efficiency, small dosage of chemicals, and small amount of waste residue generated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Oil-water separation in fresh water of embodiment 1

[0030] 1. Processing with a joint filter

[0031] 1. Engine oil

[0032] Experiment 1:

[0033] 0.1g surfactant, 16 liter tank, 10 minute cycle time.

[0034] 20 liters of water and 200 milliliters of engine oil were emulsified, and the emulsion was cooled to 4.6-5°C in a 16-liter circulation tank with a flow rate of 3 liters / minute and a pressure of 0.08 MPa.

[0035] The oil content in the lower layer of the emulsion is 2268ppm. After filtering through the combined filter, the oil content in the filtrate cannot be detected.

[0036] Experiment 2:

[0037] 0.05g surfactant, 16 liter tank, 10 minute cycle time.

[0038] Emulsify 20 liters of water and 200 ml of engine oil and allow the emulsion to cool in a 16 liter circulating water tank

[0039] To 4.6-5.5°C, the flow rate is 3 liters / minute, and the pressure is 0.08MPa. The oil content in the lower layer of the emulsion is 3511ppm, and after filtering throu...

Embodiment 2

[0059] The oil-water separation in the artificial seawater of embodiment 2

[0060] 1. Prepare artificial seawater according to the following formula

[0061] Composition of artificial sea water

[0062] Element Concentration(g / L) Mass in 20 liters (grams) NaCl 24.53 490.6 MgCl2 5.2 104 Na2SO4 4.09 81.8 CaCl2 1.16 23.2 KCl 0.695 13.9 NaHCO3 0.201 4.02 KBr 0.101 2.02 H3BO3 0.027 0.54 SrCl2 0.025 0.5 NaF 0.003 0.06

[0063] 2. Processing with combined filters

[0064] 1. Engine oil

[0065] Experiment 1:

[0066] 0.005g surfactant, 16 liter tank, 5 minute cycle time.

[0067] Emulsify 20 liters of artificial seawater and 200 ml of engine oil, and cool the emulsion to 4.7-5.2°C in a 16-liter circulating water tank with a flow rate of 3 liters / minute and a pressure of 0.08 MPa.

[0068] The oil content in the lower layer of the emulsion is 364.98ppm, and after filtering through the combine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com