Graphene silkworm excrement microporous carbon core-shell composite material as well as preparation and application thereof

A composite material and microporous carbon technology, applied in the field of carbon materials, can solve the problems of non-target biological damage environment, excessive pesticide residues in agricultural products, low pesticide utilization efficiency, etc., achieve short reaction time, reduce impact, and increase porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

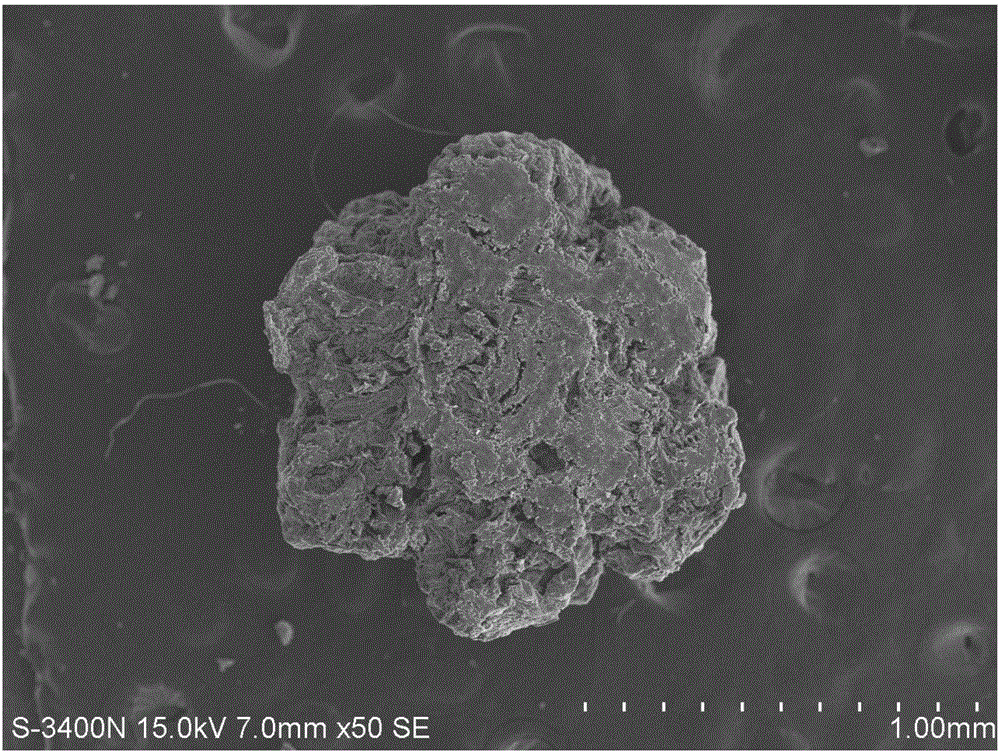

[0037] A preparation method of graphene silkworm excrement microporous carbon core-shell composite material, comprising the following steps,

[0038] (1) Mix and swell the original silkworm excrement and deionized water according to the mass-to-body ratio of 1:100. After swelling at 30°C for 3.0 hours, remove the silkworm excrement and freeze-dry it. First, freeze and pretreat at -20°C for 4 hours. Then lower the temperature to -60° C. and freeze-dry for 24 hours to obtain freeze-dried silkworm excrement.

[0039] in N 2 In the atmosphere, 10.0 g of freeze-dried silkworm excrement was raised to 750°C at a heating rate of 5°C / min, kept at 750°C for more than 2.0 hours, and then cooled to room temperature to prepare carbonized silkworm excrement.

[0040] (2) Mix carbonized silkworm excrement and KOH at a mass ratio of 1:1, 2In the atmosphere, the temperature was raised to 700°C at a rate of 5°C / min, and kept at 700°C for 5.0h to carry out the pore expansion reaction. After co...

Embodiment 2

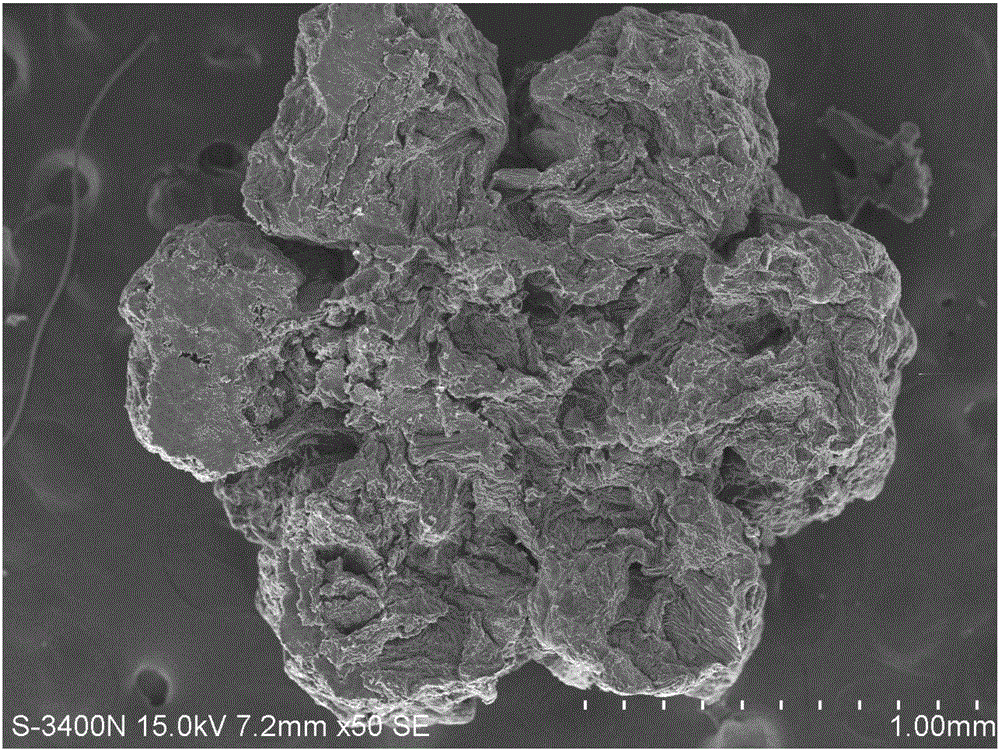

[0044] (1) Mix and swell the original silkworm excrement and deionized water according to the mass-to-body ratio of 1:120. After swelling at 35°C for 2.5 hours, remove the silkworm excrement and freeze-dry it. First, freeze it at -20°C for 3 hours. Then lower the temperature to -55° C. and freeze-dry for 36 hours to obtain freeze-dried silkworm excrement.

[0045] In an Ar atmosphere, 10.0 g of freeze-dried silkworm excrement was raised to 800 °C at a heating rate of 5 °C / min, kept at 800 °C for more than 2.0 h, and then cooled to room temperature to prepare carbonized silkworm excrement.

[0046] (2) Mix carbonized silkworm excrement and KOH at a mass ratio of 1:2, 2 In the atmosphere, the temperature was raised to 750°C at a rate of 5°C / min, and kept at 750°C for 4.0h to carry out the pore expansion reaction. After cooling down to room temperature naturally, the obtained solid was dissolved in 1mol / L HCl to wash and dissolve KOH. Then use deionized water to wash to pH ≈ 7, ...

Embodiment 3

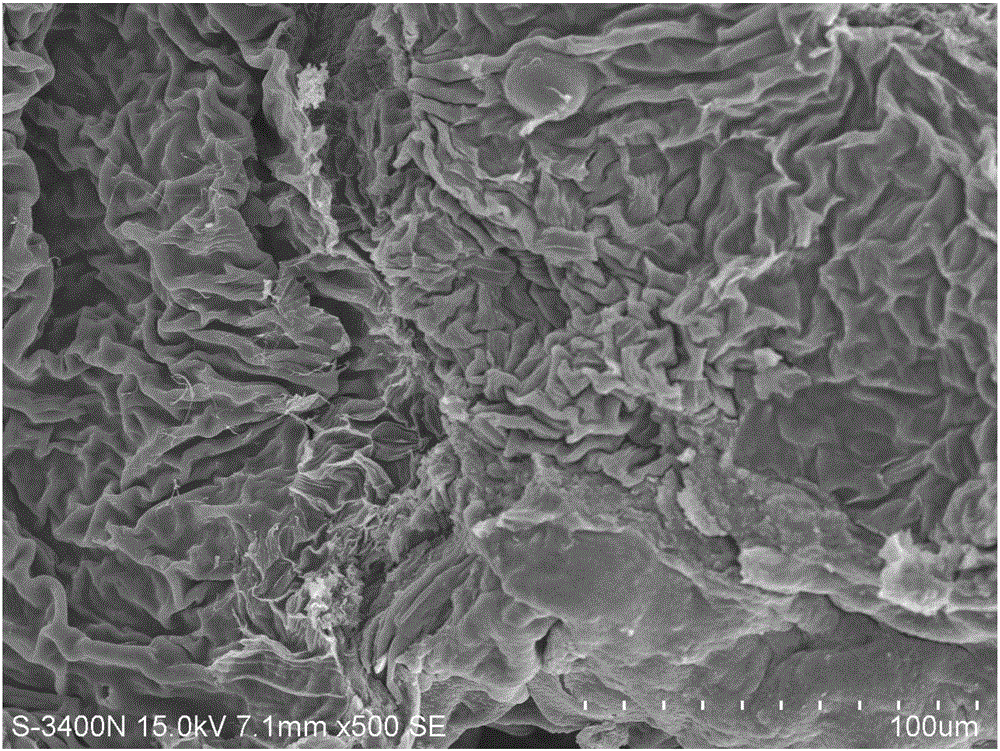

[0050] (1) Mix and swell the original silkworm excrement and deionized water according to the plastid ratio of 1:140, swell at 40°C for 2.0 hours, remove the silkworm excrement and freeze-dry it, and first freeze and pretreat it at -25°C for 2 hours, Then lower the temperature to -50° C. and freeze-dry for 48 hours to obtain freeze-dried silkworm excrement.

[0051] in N 2 In the atmosphere, 10.0 g of freeze-dried silkworm excrement was raised to 850°C at a heating rate of 5°C / min, kept at 850°C for more than 3.0h, and then cooled to room temperature to prepare carbonized silkworm excrement.

[0052] (2) Mix carbonized silkworm excrement and KOH at a mass ratio of 1:3, 2 In the atmosphere, the temperature was raised to 800°C at a rate of 5°C / min, and kept at 800°C for 3.0h to carry out the pore expansion reaction. After cooling down to room temperature naturally, the obtained solid was dissolved in 1mol / L HCl to wash and dissolve KOH. Then use deionized water to wash to pH ≈...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| Loading capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com