Layered composite photocatalyst using bimetallic nanoparticles as heterojunctions and preparation method thereof

A bimetallic nano, photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, non-metallic elements, etc., can solve problems such as poisoning, soil and water environmental pollution, achieve high activity and improve photocatalytic efficiency , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

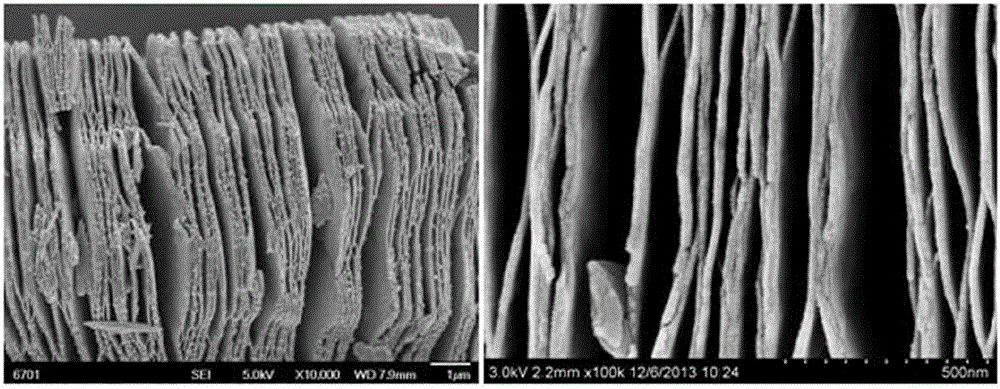

[0034] Weigh 15mg of methylcellulose and dissolve it in 40mL of deionized water. After fully stirring and dissolving, add 2mL of palladium nitrate aqueous solution containing 2mg / mL of Pd and 3mL of chloroauric acid aqueous solution containing 2.4mg / mL of Au respectively. Adjust the pH value to 7.5, and after fully mixing, use the reflux stirring device to maintain the condition of 80 ℃ and reduce it with a mixture of hydrogen and argon containing 1% hydrogen for 1 hour, and then statically place it in a constant temperature water bath at 40 ℃. Place and age for 4h to obtain a solution containing Pd-Au bimetallic nanoparticles;

[0035] In the resulting solution containing bimetallic nanoparticles, 500 mg of layered Ti 3 C 2 and 2mL of 0.5wt.% perfluorosulfonic acid resin solution, ultrasonically disperse for 30min, make it fully mixed, and then keep it at 80°C for 24h in vacuum to obtain Pd-Au bimetallic nanoparticles as heterojunction Layered Ti 3 C 2 Composite photocata...

Embodiment 2

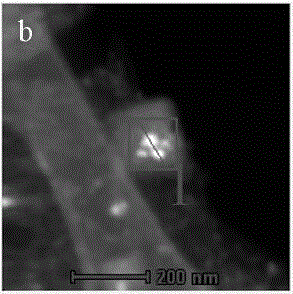

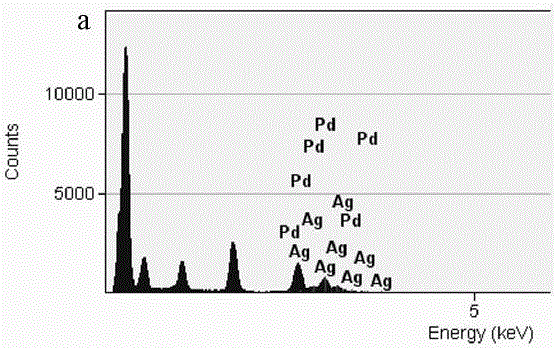

[0037] Weigh 10 mg of methyl cellulose and dissolve it in 40 mL of deionized water. After fully stirring and dissolving, add 1 mL of palladium nitrate aqueous solution containing 2 mg / mL of Pd and 4 mL of silver nitrate aqueous solution containing 2 mg / mL of Ag to adjust the pH value to 7.5, after fully mixing evenly, and then using the reflux stirring device to maintain the condition of 80 ° C with a hydrogen-containing 1% mixture of hydrogen and argon for 1 hour, and then let it stand in a constant temperature water bath at 40 ° C Aging for 4h to obtain a solution containing Pd-Ag bimetallic nanoparticles;

[0038] In the resulting solution containing bimetallic nanoparticles, 500 mg of layered Ti 3 C 2 and 2mL of 0.5wt.% perfluorosulfonic acid resin solution, ultrasonically dispersed for 30min to make it fully mixed, and then kept at 80°C for 24h in vacuum to obtain Pd-Ag bimetallic nanoparticles as heterojunction Layered Ti 3 C 2 Composite photocatalyst B.

Embodiment 3

[0040] Weigh 20 mg of methyl cellulose and dissolve it in 40 mL of deionized water. After fully stirring and dissolving, add 4 mL of chloroauric acid aqueous solution containing 2.4 mg / mL of Au and 5 mL of silver nitrate aqueous solution containing 2 mg / mL of Ag. Adjust the pH value to 7.5, and after fully mixing, use the reflux stirring device to maintain the condition of 80 ℃ and reduce it with a mixture of hydrogen and argon containing 1% hydrogen for 2 hours, and then statically place it in a constant temperature water bath at 40 ℃. Place and age for 4h to obtain a solution containing Au-Ag bimetallic nanoparticles;

[0041] In the resulting solution containing bimetallic nanoparticles, 500 mg of layered Ti 3 C 2 and 2mL of 0.5wt.% perfluorosulfonic acid resin solution, ultrasonically dispersed for 30min to make it fully mixed, and then kept at 80°C for 24h in vacuum to obtain Au-Ag bimetallic nanoparticles as heterojunction Layered Ti 3 C 2 Composite photocatalyst C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com