Method for modifying catalytic cracking equilibrium agent

A catalytic cracking and balancing agent technology, which is applied in chemical instruments and methods, catalyst regeneration/reactivation, physical/chemical process catalysts, etc., can solve the problems of limited pore cleaning, low efficiency, and decreased activity, and achieve surface improvement. The effect of acidic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

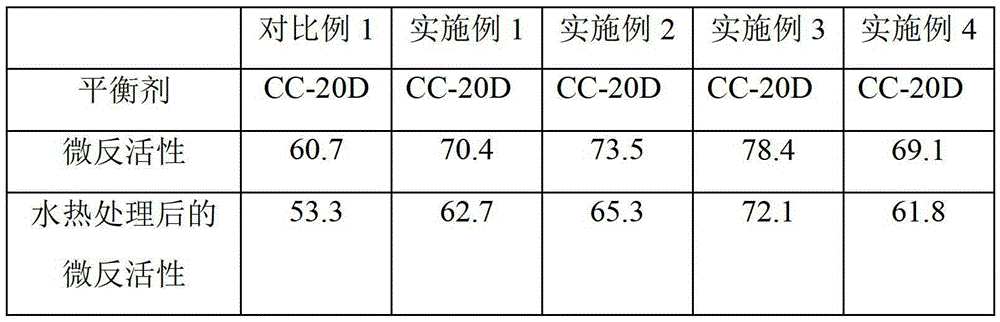

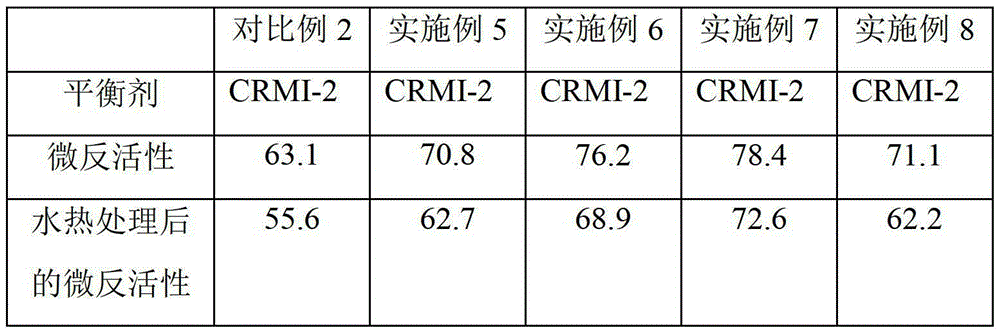

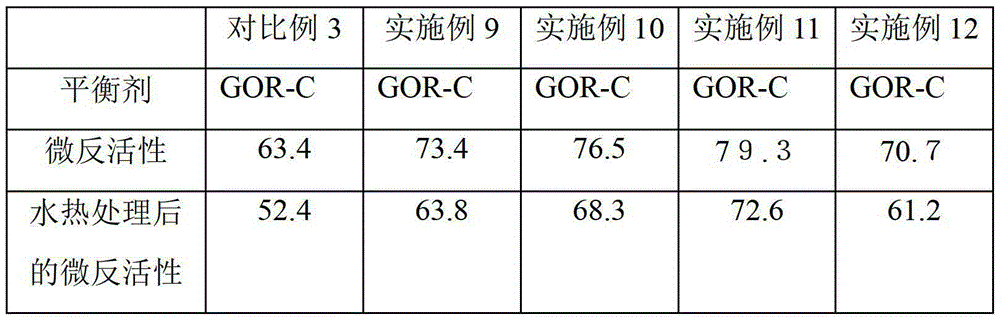

Embodiment 1

[0041] Mix the catalytic cracking balancer A that has been roasted at 450°C for 1 hour with oxygen enrichment according to the mass ratio of catalyst:water:phosphoric acid=1:10:0.02, stir at 80°C for 1.5 hours, filter, wash, and dry at 110°C . Then the balancing agent obtained is according to balancing agent: water: ReCl 3 =1:10:0.02 mass ratio mixed, adjusted pH=5, exchanged at 80°C for 1.5 hours, filtered, dried at 110-130°C after washing, and roasted at 600°C for 2 hours to obtain the treated catalytic cracking balancer, Test its microreactive activity, and then measure its microreactive activity after hydrothermal aging treatment at 800°C for 4 hours. The results are shown in Table 2.

Embodiment 2

[0043] The catalytic cracking balance agent A that was roasted at 500°C for 1 hour was mixed according to the mass ratio of catalyst:water:hydrochloric acid=1:10:0.02, stirred at 80°C for 2 hours, filtered, washed, repeated 2 times, in Dry at 110-130°C. Then the catalyst obtained according to catalyst: water: CuCl 2 =1:10:0.04 mass ratio mixed, adjusted pH=5 with ammonia water, exchanged at 80°C for 1.5 hours, filtered, dried at 110-130°C after washing, and roasted at 600°C for 2 hours to obtain the catalytic cracking equilibrium after treatment Agent, test its micro-reaction activity, and then measure its micro-reaction activity after hydrothermal aging at 800°C for 4 hours. The performance is shown in Table 2.

Embodiment 3

[0045] The catalytic cracking balance agent A after 550 DEG C oxygen-enriched roasting treatment for 2 hours was mixed according to the mass ratio of catalyst: water: phosphoric acid = 1:8:0.02, stirred at 75 DEG C for 2 hours, filtered, washed, repeated 2 times, Dry at 110-130°C. Then the catalyst obtained according to catalyst: water: ReCl 3 =1:8:0.06 mass ratio mixed, adjusted pH=6 with ammonia water, exchanged at 75°C for 2 hours, filtered, washed, dried at 110-130°C, roasted at 650°C for 2 hours to obtain the catalytic cracking equilibrium after treatment Agent, test its micro-reaction activity, and then measure its micro-reaction activity after hydrothermal aging at 800°C for 4 hours. The performance is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com